MAN B&W 13.01

Page 1 of 1

MAN Diesel

MAN B&W 65-60MEGI 198 89 70-6.2

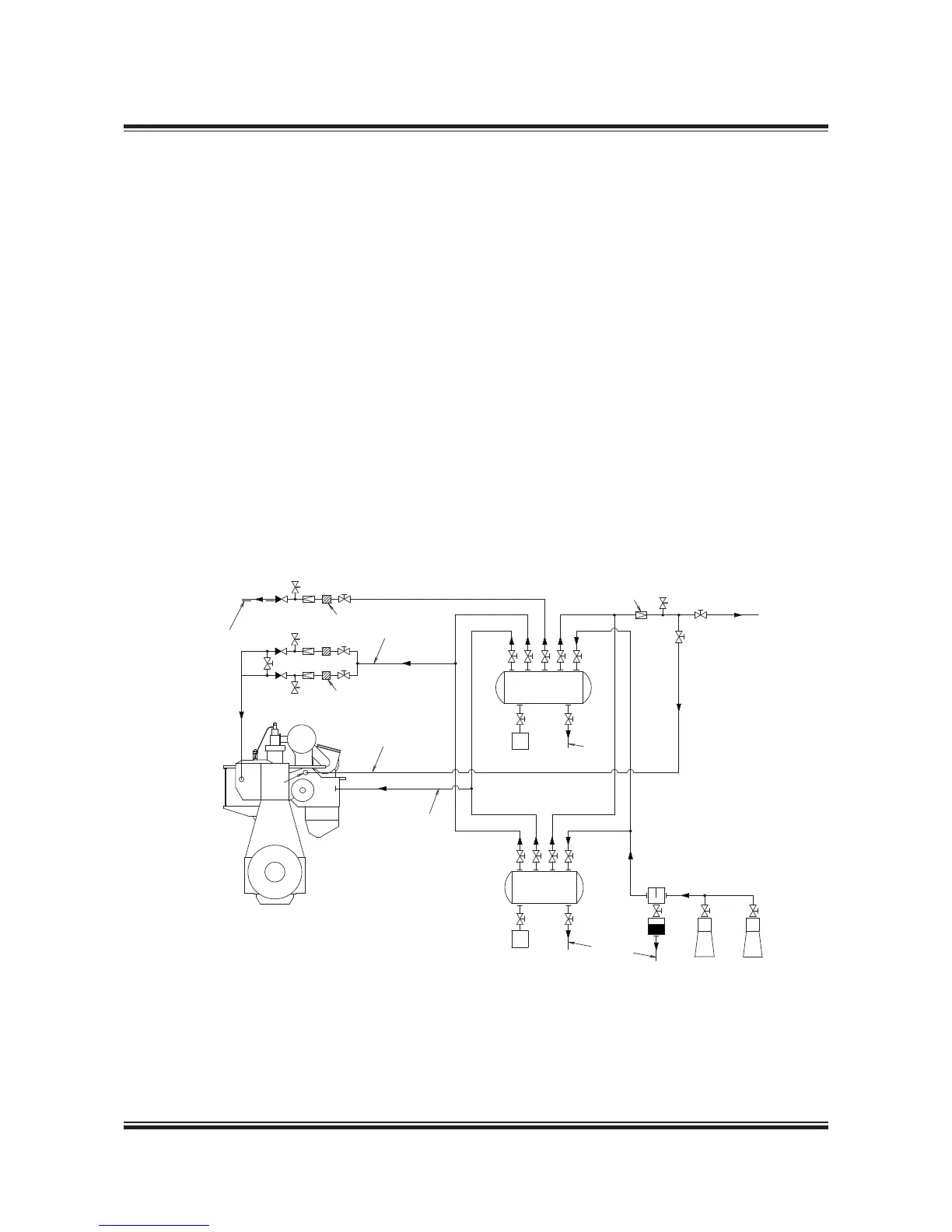

Fig. 13.01.01: Starting and control air systems

The starting air of 30 bar is supplied by the start-

ing air compressors to the starting air receivers

and from these to the main engine inlet ‘A’.

Through a reduction station, filtered compressed

air at 7 bar is supplied to the control air for ex-

haust valve air springs, through engine inlet ‘B’

Through a reduction valve, compressed air is sup-

plied at 10 bar to ‘AP’ for turbocharger cleaning

(soft blast), and a minor volume used for the fuel

valve testing unit.

Through a reduction valve, compressed air is sup-

plied at 1.5 bar to the leakage detection and venti-

lation system for the double-wall gas piping.

Please note that the air consumption for control

air, safety air, turbocharger cleaning, sealing air for

exhaust valve, for fuel valve testing unit and vent-

ing of gas pipes are momentary requirements of

the consumers.

The components of the starting and control air

systems are further desribed in Section 13.02.

For information about a common starting air sys-

tem for main engines and MAN Diesel & Turbo

auxiliary engines, please refer to our publication:

Uni-concept Auxiliary Systems for Two-Stroke Main

Engines and Four-Stroke Auxiliary Engines

The publication is available at www.marine.man.eu

→ ’Two-Stroke’ → ’Technical Papers’.

556 74 77-6.2.0

Oil & water

separator

To bilge

Reduction station

Pipe, DN25 mm

Pipe a, DN *)

Starting air

receiver 30 bar

Starting air

receiver 30 bar

Filter,

40 μm

To

bilge

Main

engine

Air compressors

To fuel valve

testing unit

BAP

A

Reduction valve

PI

PI

Pipe, DN25 mm

Filter,

40 μm

To gas piping double-wall

venting air intake

Heat tracing by

jacket water or

steam

The letters refer to list of ‘Counterflanges’

*) Pipe a nominal dimension: DN125 mm

Starting and Control Air Systems

Loading...

Loading...