MAN B&W 14.02

Page 1 of 2

MAN Diesel

198 85 47-8.0MAN B&W S90ME-C9/-GI, G80-60ME-C9/-GI,

S/L70-60ME-C8/-GI TII .2 engines

S80ME-C9/-GI TII .4 engines

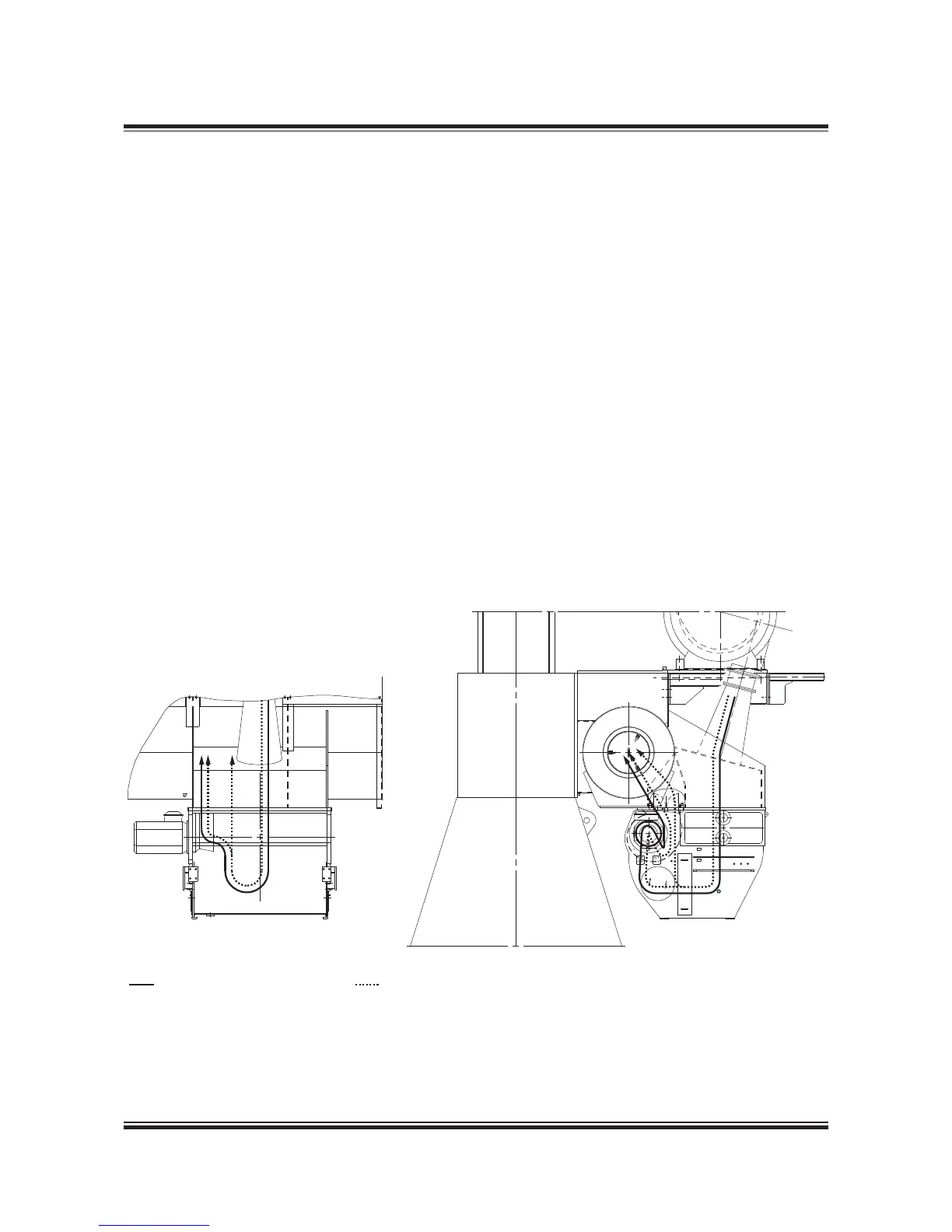

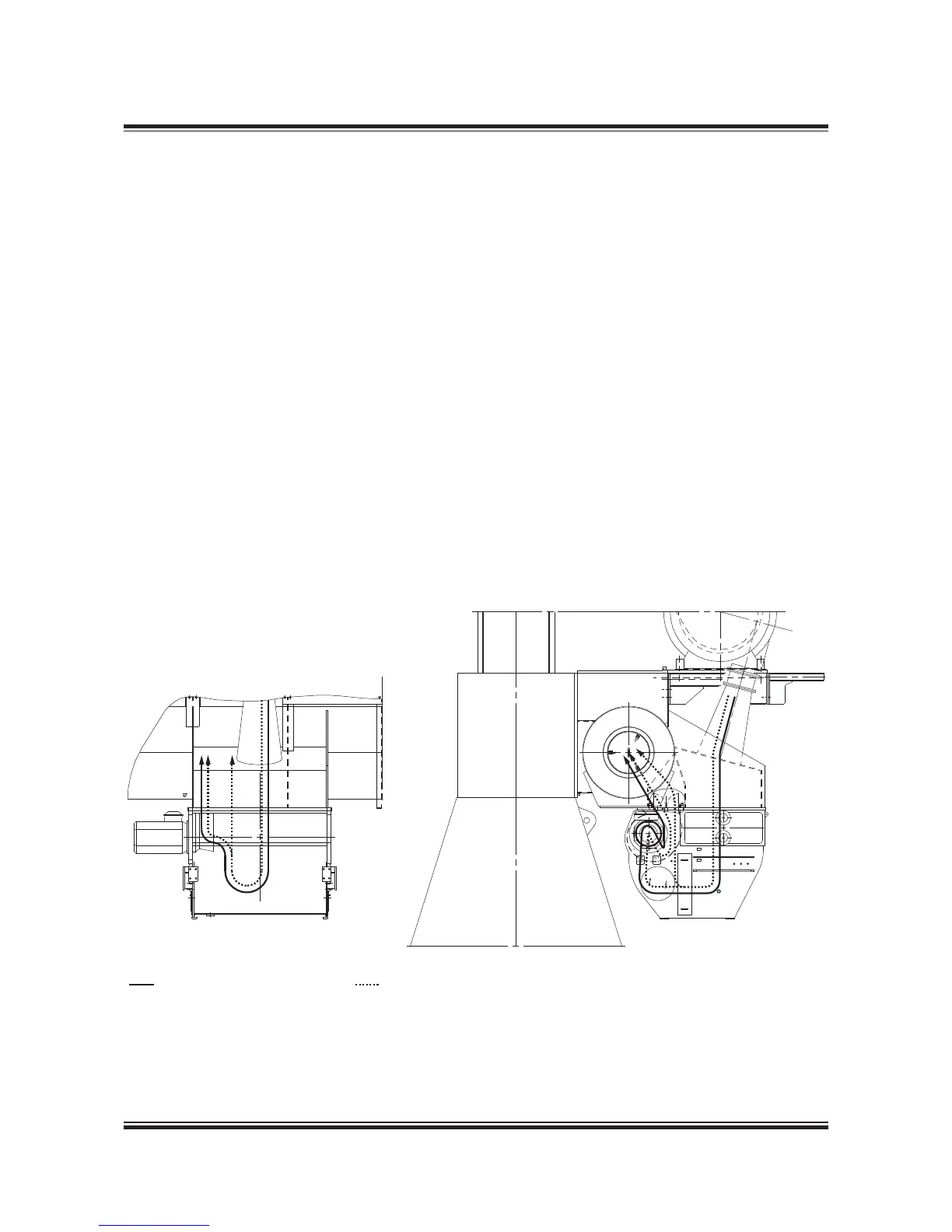

Running with auxiliary blower Running with turbocharger

Auxiliary Blowers

The engine is provided with a minimum of two

electrically driven auxiliary blowers, the actual

number depending on the number of cylinders as

well as the turbocharger make and amount.

The auxiliary blowers are integrated in the reversing

chamber below the scavenge air cooler. Between

the scavenge air cooler and the scavenge air re-

ceiver, nonreturn valves are fitted which close

automatically when the auxiliary blowers start

supplying the scavenge air.

Auxiliary blower operation

The auxiliary blowers start operating consecu-

tively before the engine is started and will ensure

complete scavenging of the cylinders in the start-

ing phase, thus providing the best conditions for a

safe start.

During operation of the engine, the auxiliary blow-

ers will start automatically whenever the blower

inlet pressure drops below a preset pressure,

corresponding to an engine load of approximately

25-35%.

The blowers will continue to operate until the

blower inlet pressure again exceeds the preset

pressure plus an appropriate hysteresis (i.e. taking

recent pressure history into account), correspond-

ing to an engine load of approximately 30-40%.

Emergency running

If one of the auxiliary blowers is out of function,

the other auxiliary blower will function in the sys-

tem, without any manual adjustment of the valves

being necessary.

Fig. 14.02.01: Scavenge air system, integrated blower

178 63 77-1.0

Loading...

Loading...