MAN B&W 4.05

Page 2 of 9

MAN Diesel

MAN B&W 98-60 engines

198 57 97-7.5

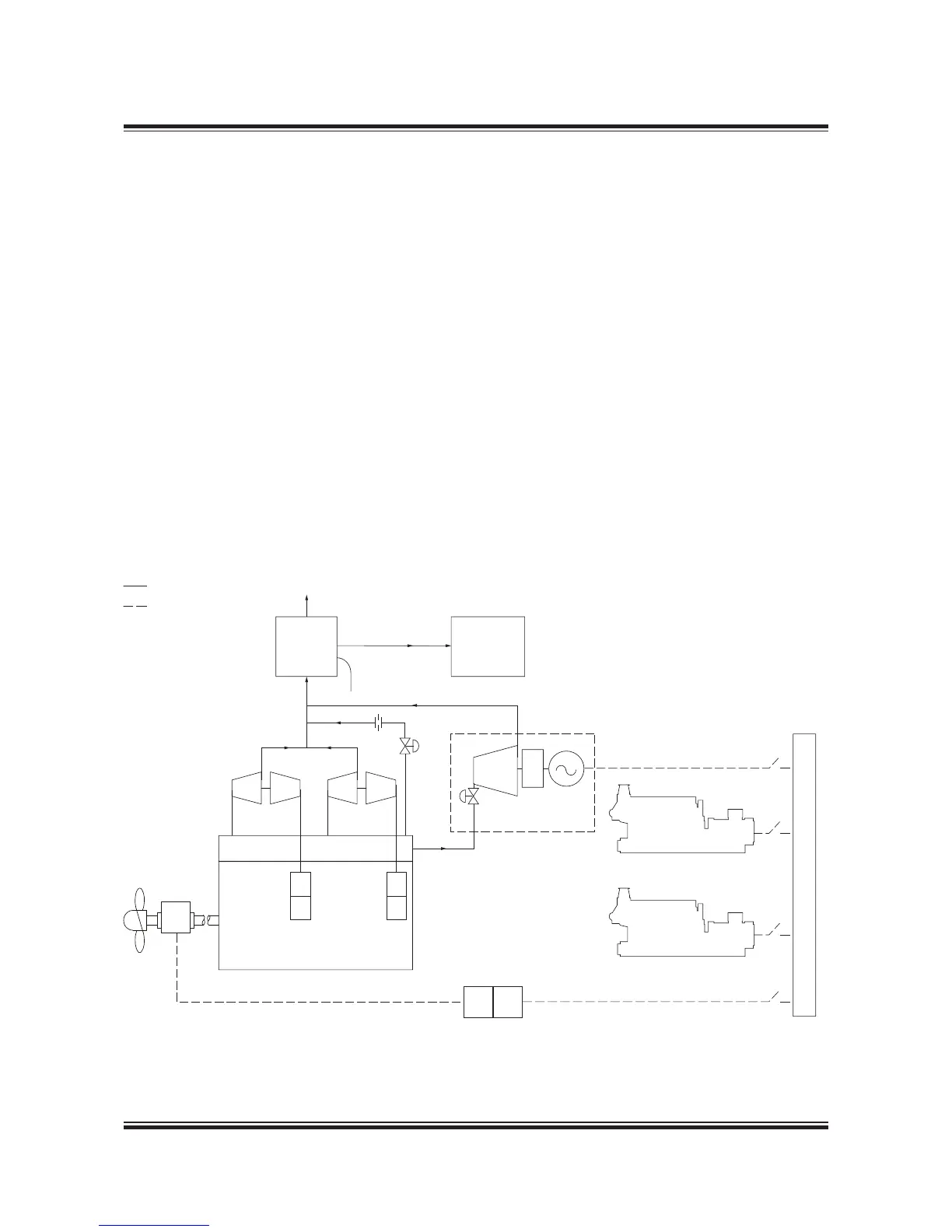

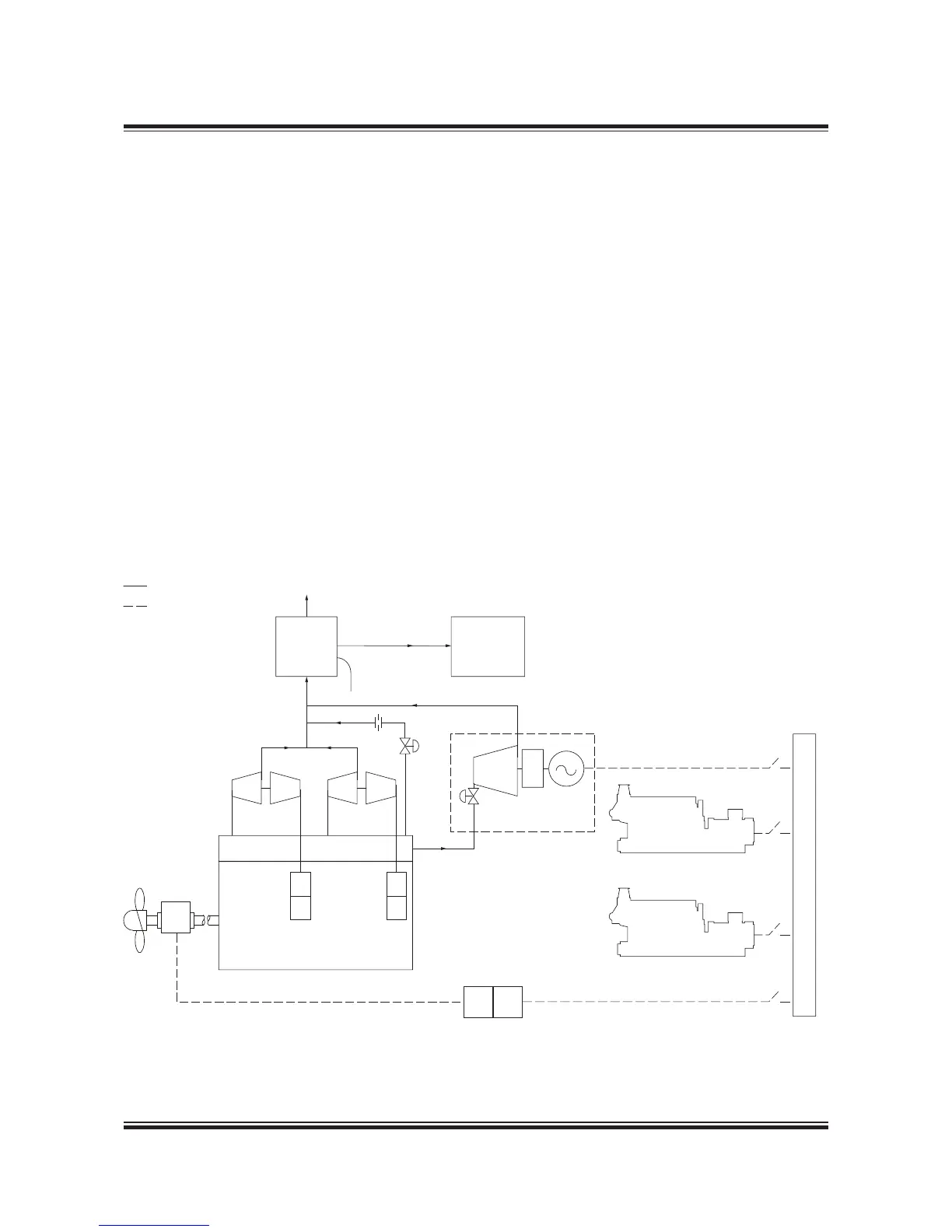

Exhaust gas

To funnel

TCS-PTG

Frequency converter

Main

switchboard

GenSet

GenSet

Piping

Electrical wiring

Exhaust gas receiver

Main engine

Scavenge

air cooler

TC TC

PTO/

PTI

Power

turbine

~/~ OO

Steam

boiler

Steam for

heating

services

178 63 80-5.0

Fig. 4.05.01: PTG diagram

Power Turbine Generator (PTG)

The power turbines of today are based on the dif-

ferent turbocharger suppliers’ newest designs of

high efficiency turbochargers, i.e. MAN TCA, ABB

A-L and Mitsubishi MET turbochargers.

MAN Diesel & Turbo offers PTG solutions called

TCS-PTG in the range from approx. 1,000 kW to

5,000 kW, see Fig. 4.05.02.

The power turbine basically is the turbine side of

a normal high-efficient turbocharger with some

modifications to the bearings and the turbine

shaft. This is in order to be able to connect it to

a gearbox instead of the normal connection to

the compressor side. The power turbine will be

installed on a separate exhaust gas pipe from the

exhaust gas receiver, which bypasses the turbo-

chargers.

The performance of the PTG and the main engine

will depend on a careful matching of the engine

turbochargers and the power turbine, for which

reason the turbocharger/s and the power turbine

need to be from the same manufacturer. In Fig.

4.05.01, a diagram of the PTG arrangement is

shown.

The newest generation of high efficiency turbo-

chargers allows bypassing of some of the main

engine exhaust gas, thereby creating a new bal-

ance of the air flow through the engine. In this

way, it is possible to extract power from the power

turbine equivalent to 3.5% of the main engine’s

SMCR, when the engine is running at SMCR.

Loading...

Loading...