3 - 18

C - EVERY 250 HOURS SERVICE

Carry out the operations described previously as well as the following operations.

C1 - FAN BELT BELT TENSION

CHECK - ADJUST

- Open the I.C. engine compartment.

- Check the belt for signs of wear and cracks and change if necessary (See

FILTERS CARTRIDGES AND BELTS in SECTION 3 - MAINTENANCE).

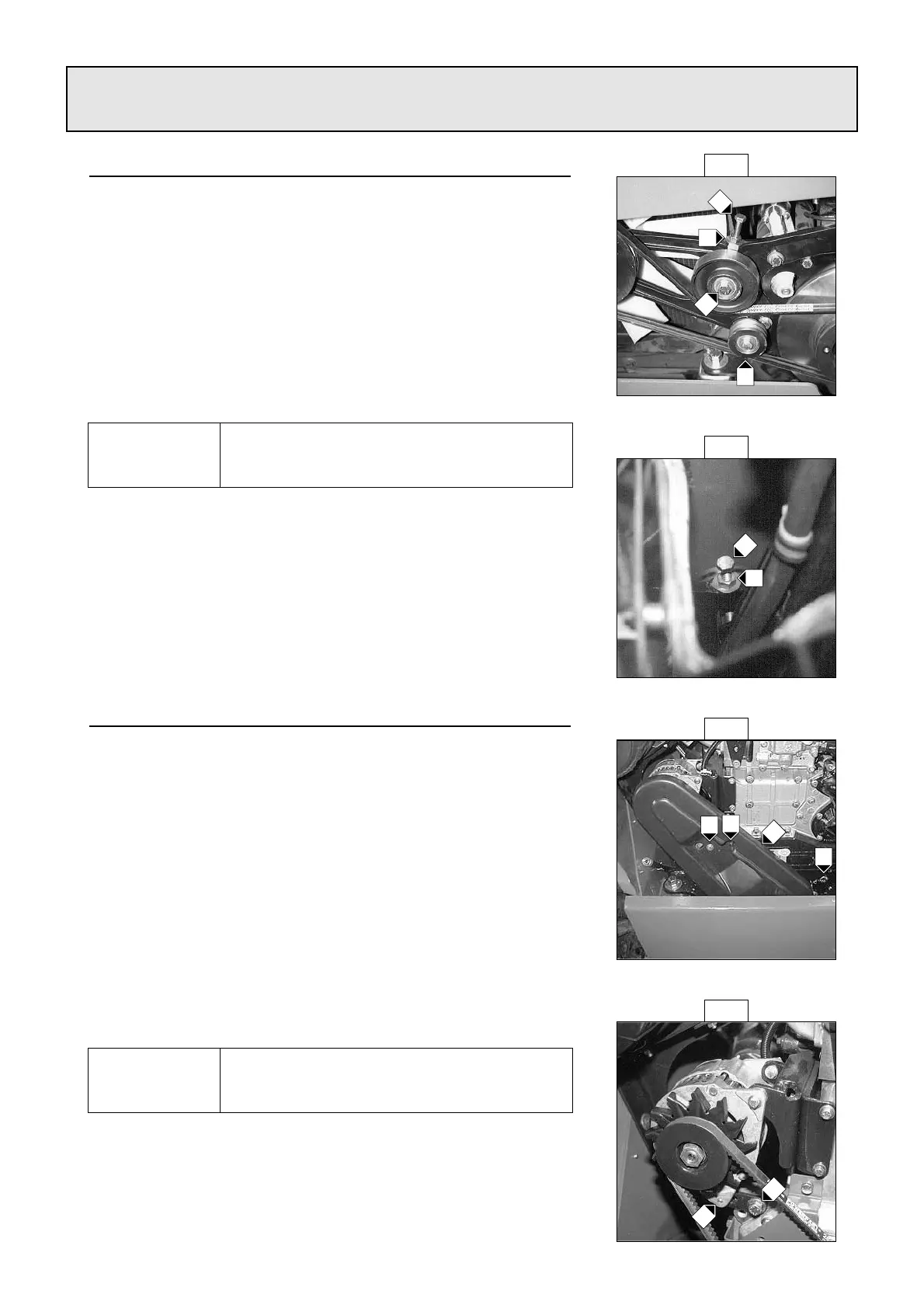

- Loosen screw 1 (Fig. C1/1) on the tension pulley.

- Loosen lock nut 2 (Fig. C1/1 and C1/2) and screw 3 (Fig. C1/1 and C1/2).

- Bring the belt just into contact with pulley 4 (Fig. C1/1) (On the lift truck,

check this operation by feel).

- Make a mark on the head of screw 3 (Fig. C1/1 and C1/2) and tighten,

turning it 5 times.

- Tighten the lock nut 2 (Fig. C1/1 and C1/2).

C2 - A

LTERNATOR

/ CRANKSHAFT BELT TENSION

CHECK - ADJUST

- Open the I.C. engine compartment.

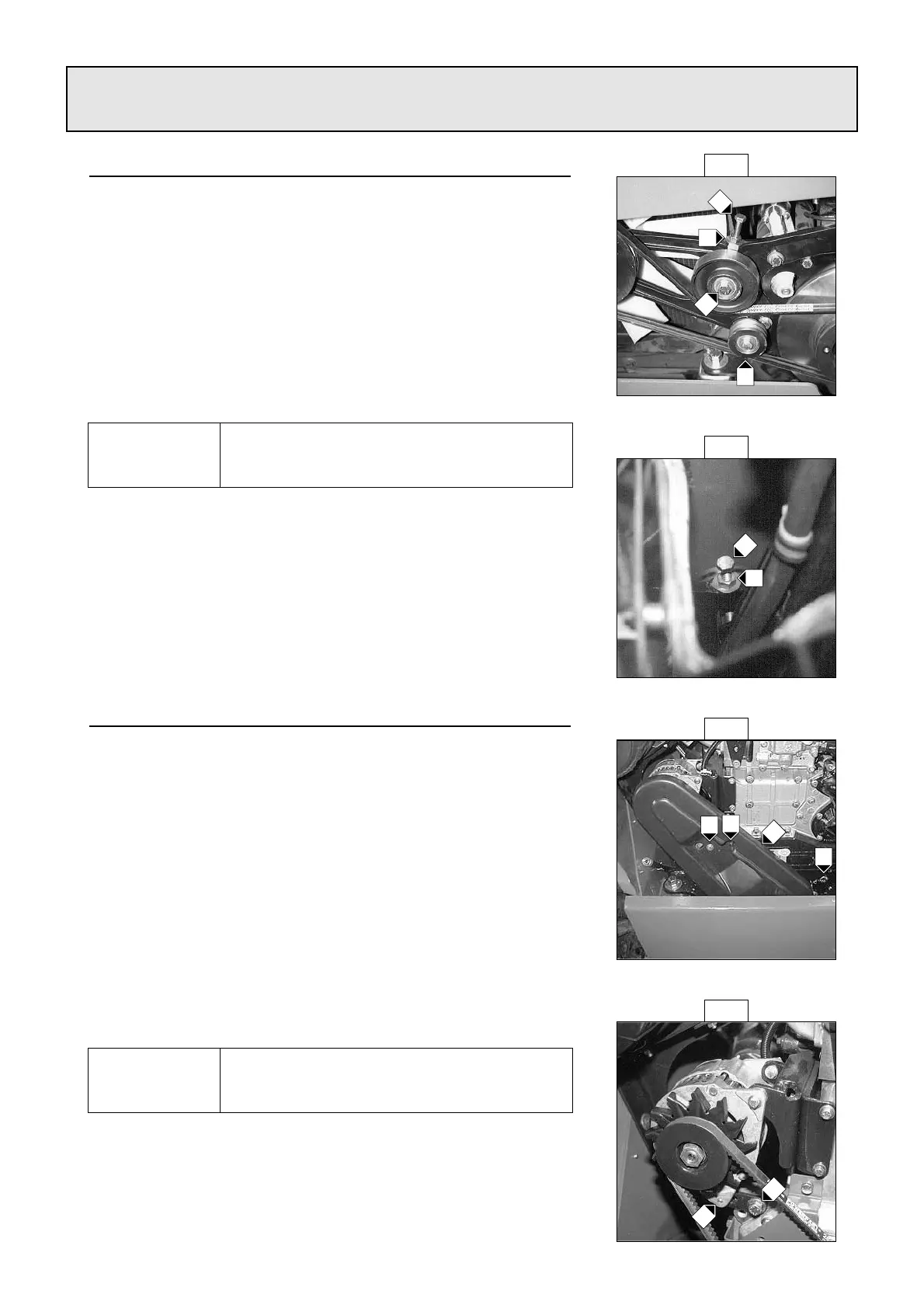

- Unscrew the fastening screws 1 (Fig. C2/1).

- Lay down the protective guard 2 (Fig. C2/1).

- Check the belt for signs of wear and cracks and change if necessary (See

FILTERS CARTRIDGES AND BELTS in SECTION 3 - MAINTENANCE).

- Check the belt tension between the pulleys of the crankshaft and of the

alternator.

- Under a normal pressure exerted with the thumb (45N or 33 lbs), the tension

should be approximately 10 mm (3/8”).

- Carry out adjustments if necessary.

- Untighten screws 3 (Fig. C2/2) by two to three thread turns.

- Swivel the alternator assembly so as to obtain the belt tension required.

- Retighten screws 3 (Fig. C2/2).

- Put the protective guard back 2 (Fig. C2/1).

C1/2

C1/1

2

3

1

2

3

4

C2/2

3

3

C2/1

1

1

1

2

When changing the fanbelt, tighten screw 3 (Fig. C1/1

and C1/2) by one and a half turns, having allowed the

I.C. engine to idle for 30 minutes.

IMPORTANT

If the alternator belt has to be changed, check the

tension again after the first 20 hours of operation.

IMPORTANT

Loading...

Loading...