3 - 26

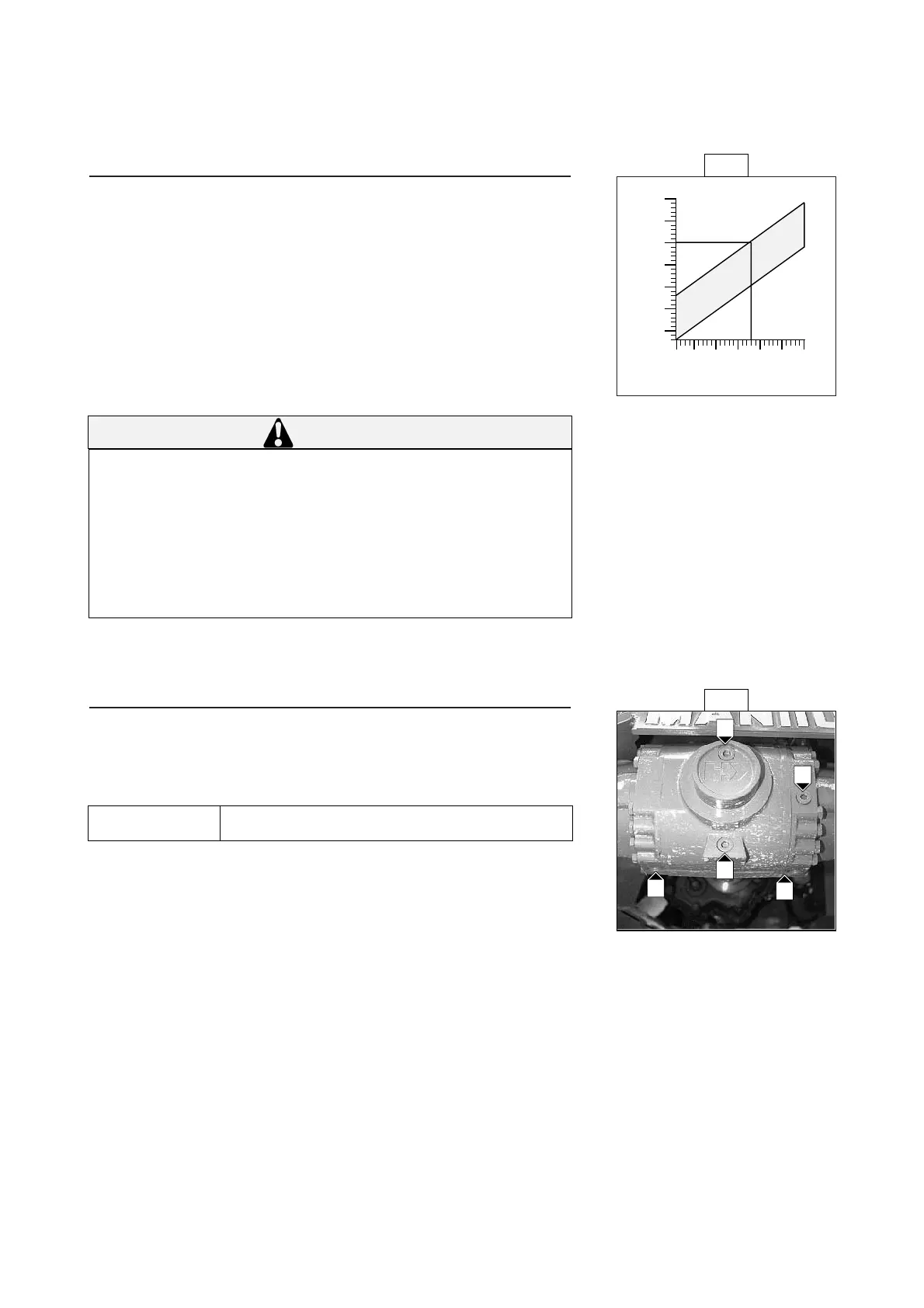

D10 - BATTERY ELECTROLYTE DENSITY

CHECK

The electrolyte density varies depending on the temperature concerned, but a

minimum of 1260 at 16°C (61°F) must be maintained. In the shaded area

(Fig. D10), the battery is in a normal charge condition. Readings above this

zone indicate that the battery needs to be recharged.

The density should not vary more than 0.025 units between cells.

- Check the electrolyte density in each battery cell using a hydrometer.

- Do not carry out this check immediately after topping up with distilled water.

Recharge the battery for at least an hour before checking the battery

electrolyte density.

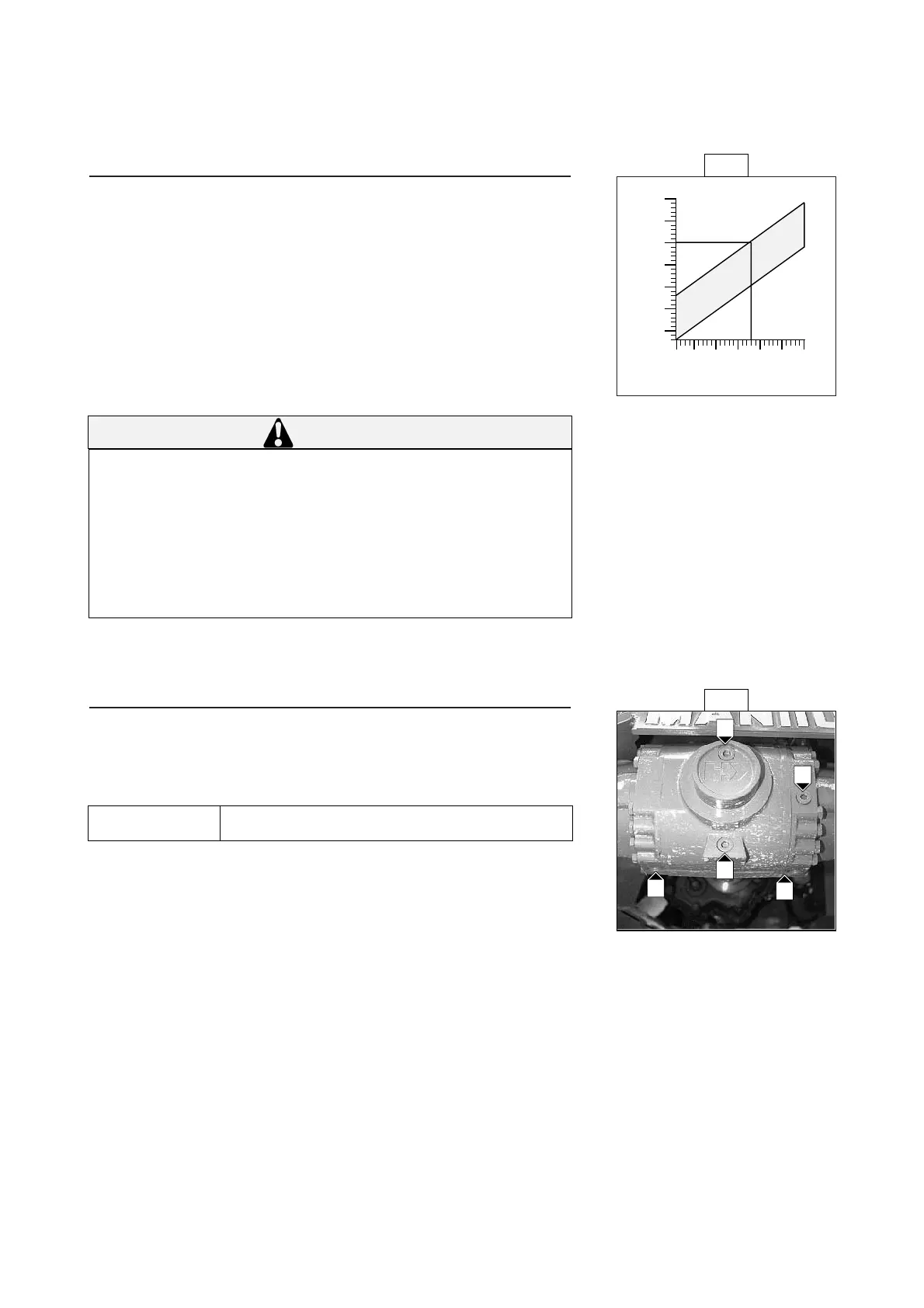

D11 - F

RONT AND REAR AXLE DIFFERENTIAL OIL

DRAIN

Place the lift truck on level ground with the engine stopped and the differential

oil still warm.

- Place a container under drain plugs 1 (Fig. D11) and unscrew the plugs.

- Remove level plug 2 (Fig. D11) and filler plug 3 (Fig. D11) in order to ensure

that the oil is drained properly.

- Refit and tighten drain plugs 1 (Fig. D11) (Tightening torque 34 to 49 N.m or

25 - 36 ft/lbs).

- Fill up with oil (See LUBRICANTS AND FUEL in SECTION 3 -

MAINTENANCE) by filler port 3 (Fig. D11).

- The level is correct when the oil level is flush with the edge of port 2 (Fig.

D11).

- Check for any possible leaks at the drain plugs.

- Refit and tighten level plug 2 and filler plug 3 (Fig. D11) (Tightening torque

34 to 49 N.m or 25 - 36 ft/lbs).

- Repeat this operation for the rear axle differential.

D10

1.240

1.250

1.260

1.270

1.280

1.290

1.300

-10

14

-18

0

°C

°F

0

32

10

50

20

68

30

86

40

104

D11

1

1

1

2

3

Handling and servicing a battery can be dangerous, take the following

precautions :

- Wear protective goggles.

- Keep the battery horizontal.

- Never smoke or work near a naked flame.

- Work in a well-ventilated area.

- In the event of electrolyte being spilled onto the skin or splashed in the

eyes, rinse thoroughly with cold water for 15 minutes and call a doctor.

CAUTION

Dispose the drain oil in an ecological manner.

IMPORTANT

Loading...

Loading...