3 - 37

G2 - WHEEL

CHANGE

In the event of a wheel being changed on the public highway, make sure of the following

points:

For this operation, we advise you to use the hydraulic jack MANITOU reference 505507

and the safety support MANITOU reference 554772.

- Stop the lift truck, if possible on even and hard ground.

- To pass on stop of lift truck (see: 1 - OPERATING AND SAFETY INSTRUCTIONS: DRIVING

INSTRUCTIONS UNLADEN AND LADEN).

- Put the warning lights on.

- Immobilise the lift truck in both directions on the axle opposite to the wheel to be

changed.

- Unlock the nuts of the wheel to be changed.

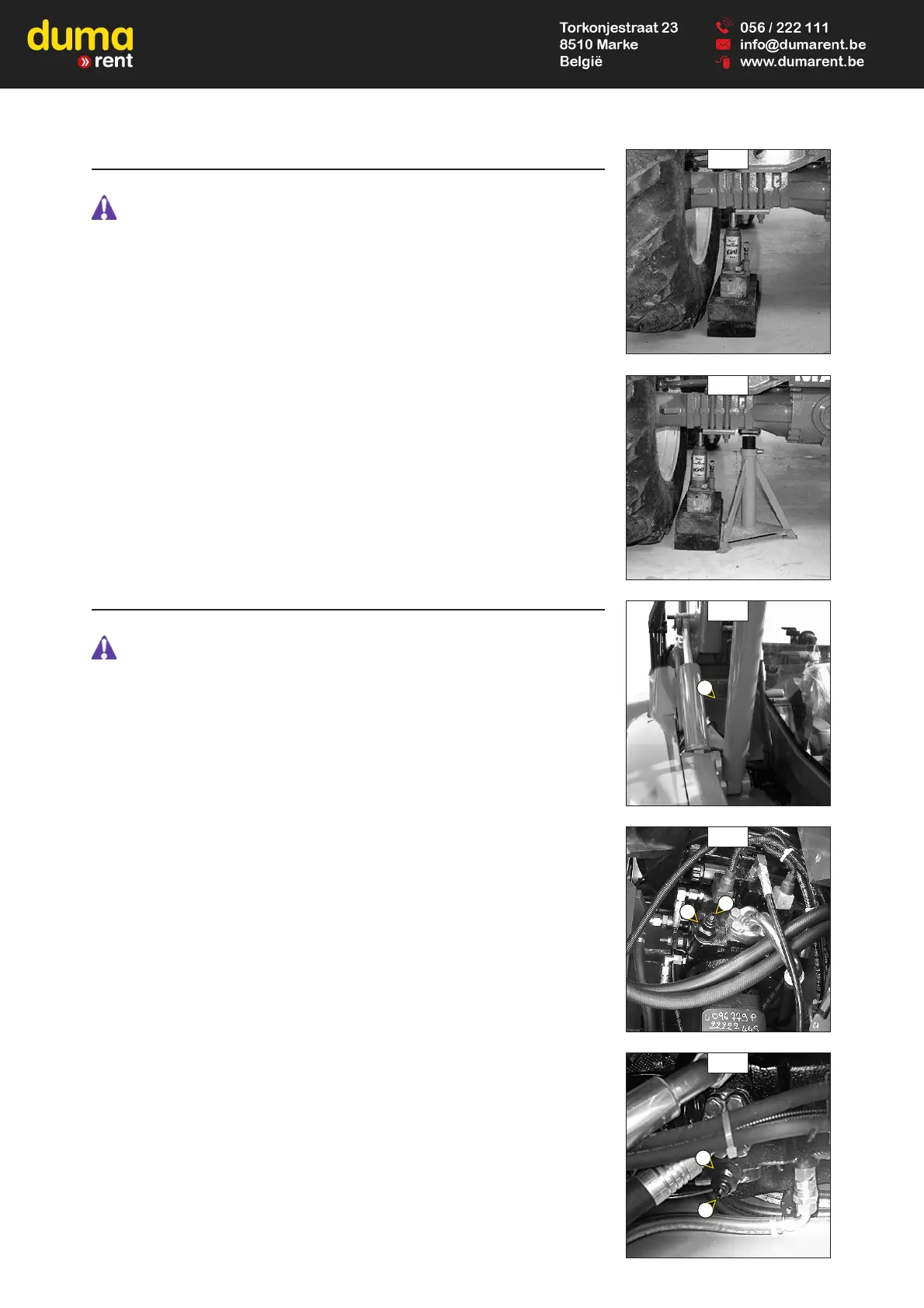

- Place the jack under the flared axle tube, as near as possible to the wheel and adjust the

jack (fig. G2/1).

- Lift the wheel until it comes off the ground and put in place the safety support under the

axle (fig. G2/2).

- Completely unscrew the wheel nuts and remove them.

- Free the wheel by reciprocating movements and roll it to the side.

- Slip the new wheel on the wheel hub.

- Refit the nuts by hand, if necessary grease them.

- Remove the safety support and lower the lift truck with the jack.

- Tighten the wheel nuts with a torque wrench (see: 3 - MAINTENANCE: A - DAILY OR EVERY

10 HOURS SERVICE for tightening torque).

G3 - LIFT TRUCK

TOW

The lift truck must be towed very slowly (less than 5 km/h) and for as short a distance as

possible (less than 100 m).

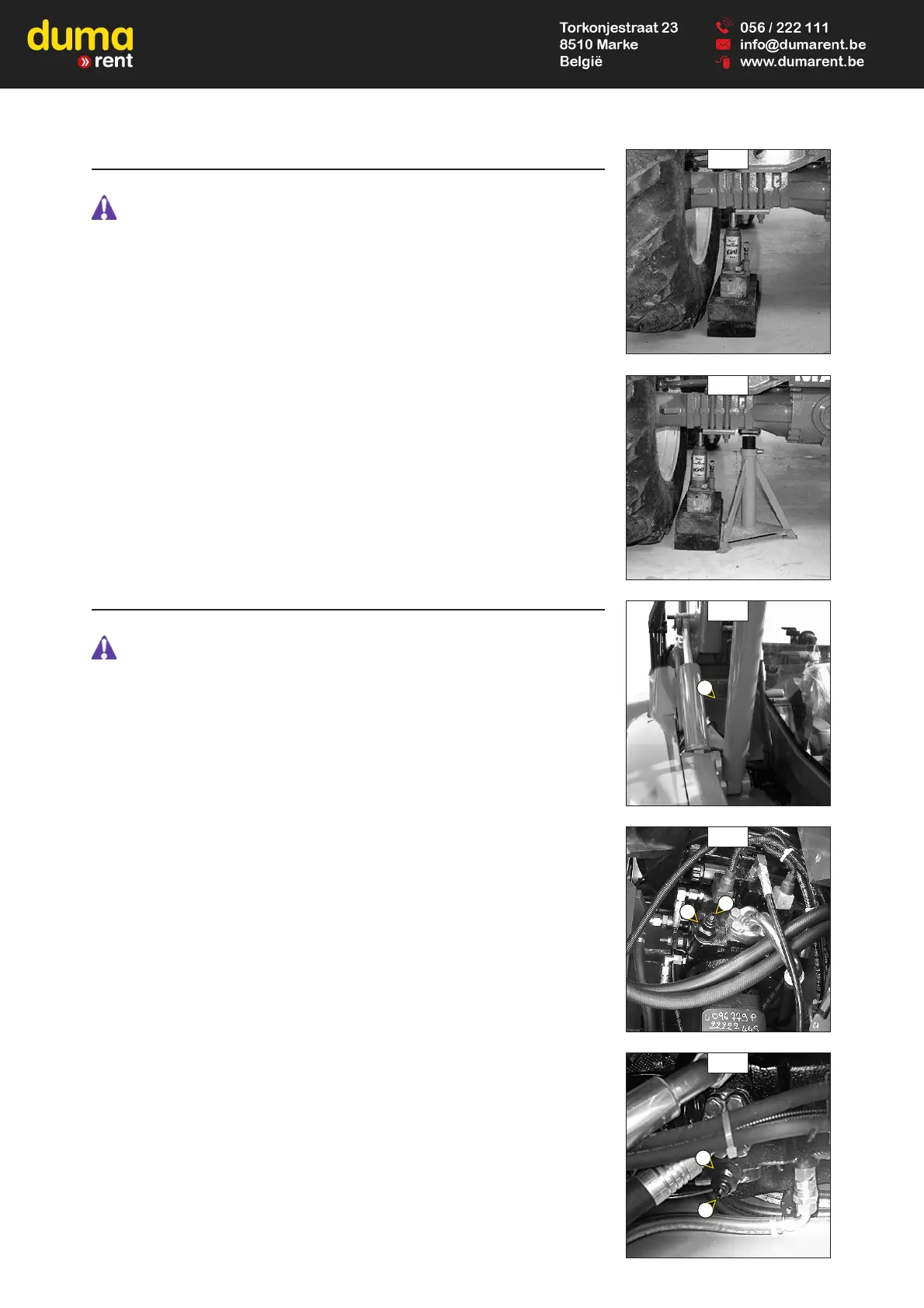

- To tow a lift truck, the high pressure limiters 2 (fig. G3/2 and fig. G3/3) must be unlocked

to avoid deteriorating the hydrostatic transmission.

- Raise the jib.

- Remove the inspection cover 1 (fig. G3/1).

- Untighten screws HC 3 (fig. G3/2 and fig. G3/3) by three turns.

- Put the warning lights on.

- Untighten the hand brake.

- After towing, proceed in the reverse order to lock the high pressure limiters.

G2/1

G2/2

G3/1

G3/2

2

G3/3

1

2

3

3

Loading...

Loading...