2 - 34

2 - SEAT BELT

IMPORTANT

In no event should the lift truck be used if the seat belt is defective (fixing, locking, cuts, tears, etc.).

Repair or replace the seat belt immediately.

- Sit correctly on the seat.

- Check that seat belt is not twisted.

- Place the seat belt at hip level.

- Attach the seat belt and check that it locks.

- Adjust the seat belt to your body shape without compressing your pelvis and without excessive slack.

3 - IGNITION SWITCH

This switch has 5 positions:

• P - Not used.

• O - Ignition switched off and engine stopped.

• I - Ignition + preheat.

• II - Not used.

• III - Start-up and returns to position I as soon as the key is released.

4 - EMERGENCY STOP BUTTON

In the event of danger, it enables the engine to be shut down, thereby cutting-off all

hydraulic movements.

IMPORTANT

Warning, hydraulic movements suddenly stop when using this button.

Warning, when driving, the lift truck will be brought to a sudden stop if the parking brake is actuated.

If possible, stop the lift truck before using the emergency stop button.

- Turn the knob to deactivate it before restarting the lift truck.

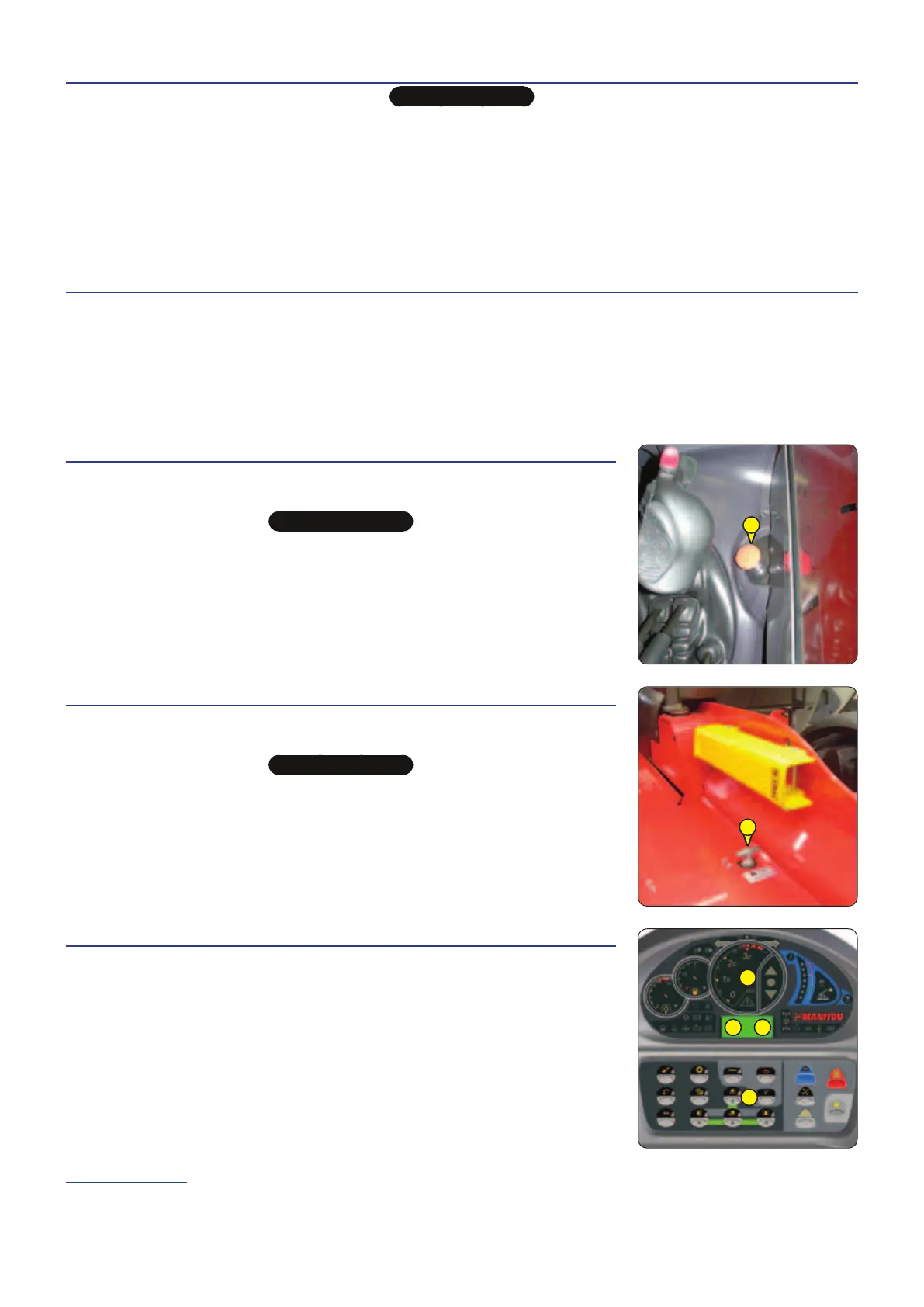

5 - BATTERY CUT-OFF

For quickly disconnecting the battery when working on the electric circuit or when

soldering, for example.

IMPORTANT

Operate the battery cut-off no less than 30 seconds after having switched off the ignition with the ignition key.

6 - MAN-MACHINE INTERFACE (MMI)

• 6A - DRIVER PRESENCE

• 6B - INSTRUMENT CONTROL PANEL

• 6C - PANEL FOR BUTTONS AND KEYBOARD

• 6D - SCREEN DISPLAY

UPDATE: In order to gain maximum advantage from the Man-Machine Interface of

your forklift truck, contact your dealer to receive the most recent version

of the software.

6A - DRIVER PRESENCE

The driver's presence is validated when the operator is correctly seated and the cab door is closed.

- It is only after this that the lift truck is operational; the operator can perform hydraulic movements and move the forklift

truck.

4

5

6A 6D

6B

6C

647563 (22/08/2017)

MT 1435/1440/1840 EASY 75D ST3B S1

Loading...

Loading...