Features

Crane Control System

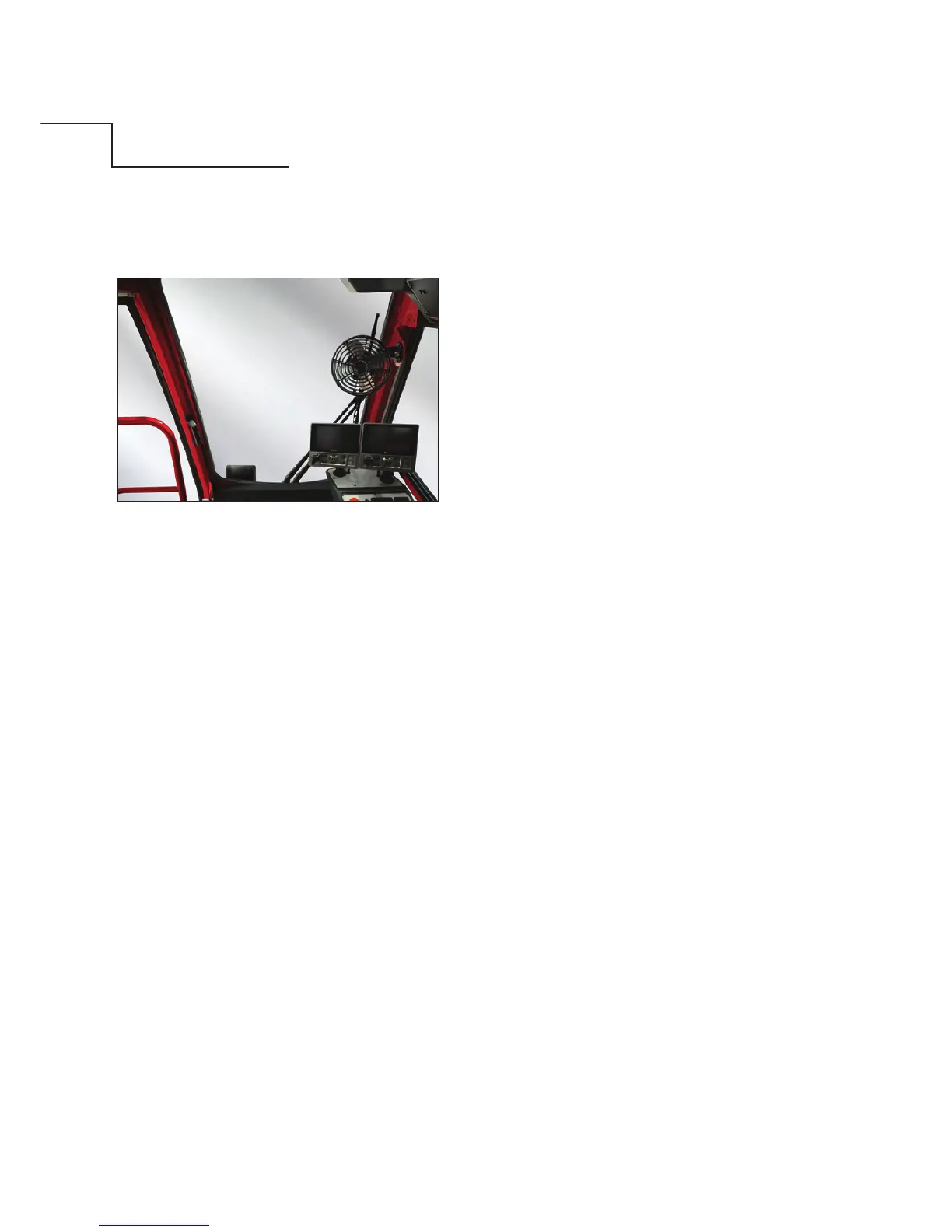

e Crane Control System oers a user-friendly interface,

two full graphic displays mounted horizontally for better

visibility, a jog dial for easier data input and ergonomic

joysticks.

Variable Position Counterweight (VPC)

e Manitowoc MLC300 features a counterweight system

which automatically positions the crane’s counterweight

as required to match lifting demands. Crane lifting

capability is optimized by automatic positioning of

the counterweight; eliminating the need for carbody

counterweight. Additionally, counterweight boxes are

designed to be common across multiple crane platforms

and will be utilized on Manitowoc Model MLC650 as

well as future new models.

Crawler Tensioning System

Each crawler is equipped with a dedicated hydraulic

cylinder and hydraulic supply, allowing independent track

tension adjustment via crane setup remote.

VPC-MAX

Capacity and boom and jib combination lengths can be

increased through addition of the exclusive VPC-MAX

attachment. e VPC-MAX attachment, utilizing all

of the standard VPC components, increases the max

load moment of the MLC300 when a 98' 5" xed mast,

VPC-MAX counterweight beam and additional 88,185

lb of counterweight is added to the base MLC300. e

position of the VPC-MAX counterweight is automatically

positioned based on lifted load, boom length or boom

and jib length and load radius.

Transport

e MLC300 is designed to be transported globally with

optimized component weights and dimensions. e MLC300

features a removable live mast shipping module and boom

inserts designed to allow lung jib inserts to ship within

the boom inserts for cost eective transport.

FACT™ Connectors

Manitowoc’s Fast Aligning Connection Technology

(FACT) automatically aligns crane components for fast,

safe and easy assembly.

Loading...

Loading...