4-- 17© 2012 Mobile Climate Control T-299 Rev. 08/2012

b. Connect an ohmmeter across switch terminals.

If the switch is good, the ohmmeter will indicate

no resistance, indicating that the contacts are

closed.

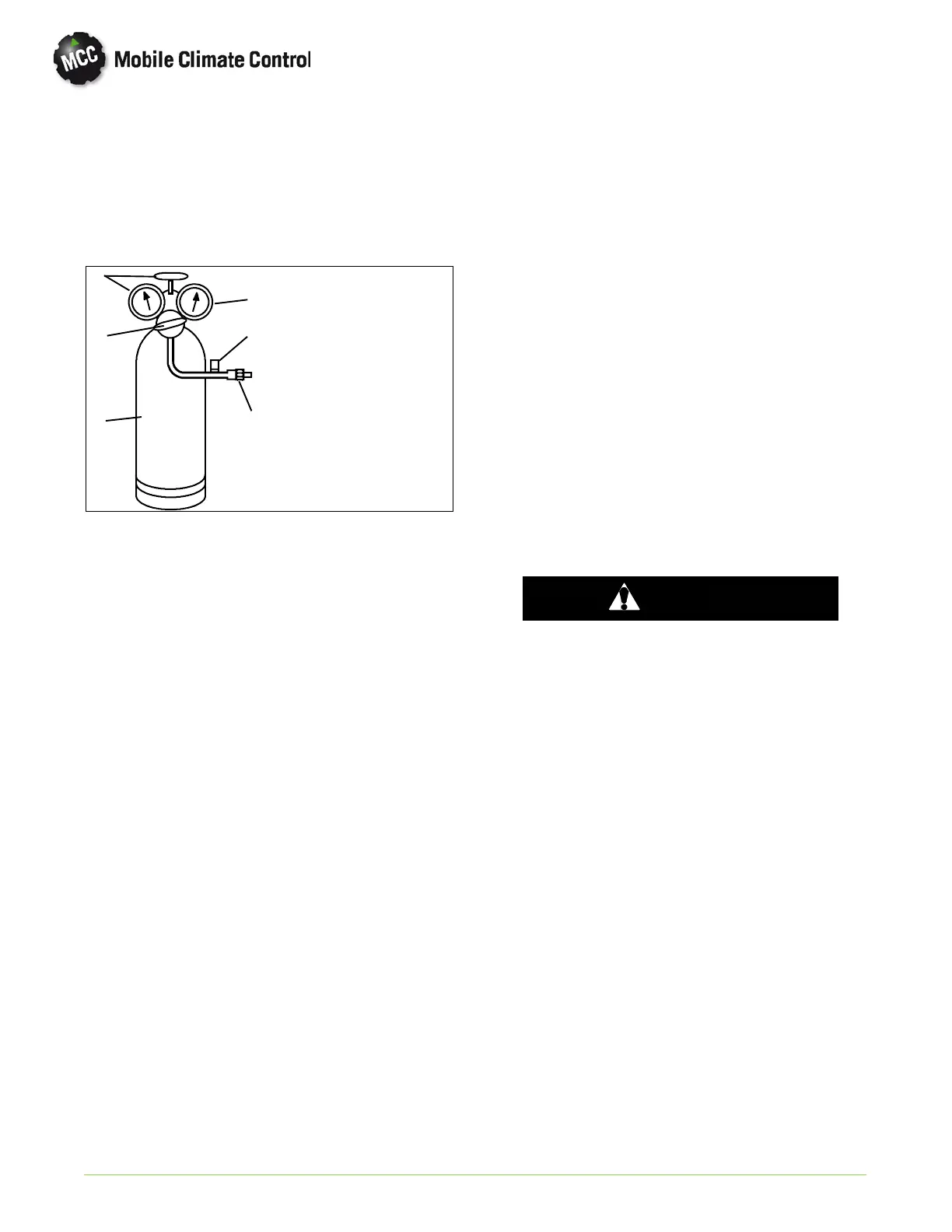

c. Con n ect switch to a cylinder of dry nitrogen. (See

Figure 4-9.

1. Cylinder Valve

and Gauge

2. Pressure

Regulator

3. Nitrogen Cylinder

4. Pressure Gauge

(0 to 400 psig =

0to36kg/cm@)

5. Bleed-Off Valve

6. 1/4 inch

Connection

1

2

3

4

5

6

Figure 4-9. Checking High Pressure Switch

d. Set n itrogen pressure regulator higher than

cutout p o int on switch being tested.(Refer to

paragraph 1.7)

e. Open cylinder valve. Slowly open the regulator

valve to increase the pressure until it reaches

cutout point. The switch should open, which is

indicated by an infinite reading on an ohmmeter

(no continuity).

f. Close cylinder valve and release p ressure th rou gh

the b leed-off valve. As pressure dro p s to cut-in

point, the switch contacts should close,

indicating no resistance (continuity) on the

ohmmeter.

g. Replace switch if it does not function as outlined

above.

4.19 MOISTURE INDICATOR (SYSTEM)

There are two types of m o isture indicators presently

in use with Mobile Climate Control systems.

1. Green/Yellow (Previous Configuration)

Green = Dry System Yellow = Wet System

2. Blue/Pink (Current Configuration)

Blue=Dry Pink=Wet

4.20 FILTER-DRIER OR RECEIVER-DRIER

Mobile Climate Control condensers are supplier with

either a filter-drier or a receiver-drier.

NOTE

All microchannel condenser assemblies are

equipped with a receiver-drier with an

integral high pressure switch.

If a pressure drop across the Filter-Drier (see

Figure 4-10) or Receiver-Drier (see Figure 4-11) is

indicated or the moisture-indicator shows an

abnormal (wet) condition, the Filter-Drier or

Receiver-Drier must be changed.

a. Check for a restricted filter by touching the filter

drier or r eceiver-drier on inlet and o utlet

connections. If there is a noticeable temperature

difference the filter is probably restricted and

should be replaced.

b. Recover refrigerant, r efer to paragraph 4.4.

c. Place a new filter-drier or receiver-drier near the

unit for immediate installation.

d. Using two open end wrenches, slowly crackopen

and remove the liquid line O-ring fittings on each

side o f the filter-drier.

WARNING

The filter-drier or receiver-drier may contain

liquid refrigerant. Slowly open the fitting

nuts and avoid contact with exposed skin or

eyes.

e. Loo sen the hose clamp(s) securing the filter drier

or receiver-drier to the condenser assembly.

f. Remove the filter-drier o r receiver drier.

Transfer high pressure switch if required.

g. Remove seal caps from the new filter-drier or

receiver-drier. Ap p ly a light coat of mineral o il to

the fittings and O'rings.

h. Assemble the new filter-drier or receiver-drier to

the liquid lines ensuring that the arrow on the

body of t he filter-drier o r receiver-drier po ints in

the direction of the refrigerant flow (liquid

refrigerant flows from the condenser to the

evaporator). Finger tighten the liquid line

fittings.

i. Tighten filter-drier or receiver-drier O-ring

fittings using two open end wrenches. Refer to

paragraph 4.10 for torque specifications.

j. Evacuate system to 500 microns by connecting a

vacuum pump as shown in Figure 4-2.

k. Charge system according to paragraph 4.8.2.

Loading...

Loading...