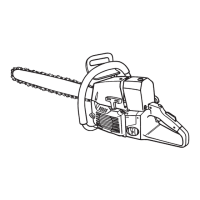

This document is an owner's manual for McCulloch MAC 110/115/120/130/140 series chain saws, providing detailed instructions for operation, maintenance, and safety.

Function Description:

The McCulloch MAC series chain saws are consumer-grade tools designed for general homeowner use, including clearing, pruning, and cutting firewood. They are powered by an internal combustion engine and feature a guide bar with a saw chain for cutting wood. Key components include a fuel tank, oil tank, manual oiler, automatic oiler, chain brake, throttle trigger, rear handle, front handle, starter cover, starter handle, ignition/stop switch, throttle latch, carburetor controls, choke lever, oil tank cap, saw chain tension adjustment screw, and muffler. The chain brake is a crucial safety feature designed to reduce the possibility of injury from kickback by stopping chain movement abruptly when activated.

Important Technical Specifications:

- Fuel: Regular grade leaded gasoline. Highly leaded, unleaded, or low-lead gasolines are not recommended.

- Fuel Mixture: McCulloch 40:1 Two-Cycle Custom Lubricant is recommended. If unavailable, a good grade SAE 40 two-cycle oil at a 20:1 ratio can be used. Fuel additives or special starting fluids are not to be used.

- Chain Lubrication: McCulloch Chain, Bar and Sprocket Oil is recommended. If unavailable, SAE 30 non-additive motor oil for temperatures above 40°F (5°C) or SAE 10 non-additive motor oil for lower temperatures. The chain oil tank should be refilled every time the fuel tank is refilled.

- Spark Plug Gap: 0.025 inches (0.635 mm).

- Carburetor Adjustment: Low and high-speed mixture needles should be opened 1 1/4 turns counterclockwise from a fully closed position. The high-speed needle's final position is typically between 1 1/4 and 1 1/2 turns for best power under load.

- Chain Sharpening File Size: 5/32 inch (3.9 mm) round file with a 30° top filing angle.

Usage Features:

- Safety First: Always read the owner's manual and supplements. Operation is restricted to mature, properly instructed individuals. Wear close-fitting protective clothing including a safety hat, shield/goggles, work shoes, heavy-duty gloves, and ear protection.

- Refueling: Refuel in a safe place, opening the fuel cap slowly. Do not overfill or spill fuel. Do not refuel a hot saw. Do not smoke while fueling or operating.

- Starting: Place the saw on a firm, flat surface. Ensure the ignition/stop switch is "ON". Use the choke lever for cold or vapor-locked engines. Depress the safety trigger, grasp the rear handle, squeeze the throttle trigger tightly, and hold down the throttle latch. Release the trigger and throttle latch button. Grip the front handle firmly (not the brake lever). Pull the starter handle slowly until engagement, then with a smooth, rapid, short-stroke motion.

- Chain Brake Operation: The chain brake is disengaged when the lever is pulled back and locked (chain can move) and engaged when the lever is in the forward position (chain stopped). It should be activated slowly and deliberately. Do not attempt to start or operate the engine with the brake engaged.

- Cutting Techniques: Hold the saw firmly with both hands. Cut at high engine speeds (full throttle). Pre-plan a safe exit path.

- Felling: Use an undercut (Type "A" for small trees, "B" for square butt, "C" variation of "A"). The notch should be about 1/3 of the tree's diameter. Do not cut through to the notch; an uncut band of wood acts as a hinge. For wood larger than the bar, make two cuts.

- Bucking: Stand on the uphill side when bucking on a slope. For logs supported along their entire length, cut from the top (overbuck). For logs supported on one end, make a first cut from the bottom (underbuck) 1/3 of the diameter to prevent splintering, then overbuck to meet the first cut. For logs supported on both ends, first overbuck 1/3 of the diameter, then underbuck to meet the first cut.

- Limbing: Keep the log off the ground. Do not remove supporting limbs until after the log is bucked.

- Kickback Prevention: Hold the saw firmly with both hands, using a firm grip with thumbs and fingers encircling the handles. Be aware of what you are cutting. Kickback can be caused by striking limbs/objects with the saw tip, striking metal/cement, or running the engine slowly during a cut. Use low kickback chain, chain brakes, and handguards.

- New Engine Break-In: Run the engine at one-third throttle for the first few minutes, then increase to half-throttle. Cut small limbs or logs initially. Check chain tension frequently and use the manual oiler often. A slightly richer fuel mixture (one-eighth turn counterclockwise on high-speed or low-speed mixture needles) is advisable during break-in.

Maintenance Features:

- General: Keep the saw, bar, and chain clean. Do not allow filters, muffler, or cylinder fins to become plugged. Do not use dirty fuel or chain oil. All service other than specified in the manual should be performed by an authorized McCulloch Servicing Dealer.

- Spark Plug: Keep clean and properly gapped (0.025 in / 0.635 mm). Disconnect the rubber connector, remove the plug, clean electrodes with emery cloth/sandpaper, adjust gap by bending the side electrode, and reinstall.

- Fuel Tank Vent: Ensure the fuel tank or cap is vented to prevent pressure or vacuum buildup. If plugged, have a dealer service it.

- Air Filter: Keep clean. Remove the cover, lift off the filter, blow clean with low air pressure or wash in fuel mix, dry, and reinstall. Never operate without the air filter.

- Starter Cover and Cooling Fins: Keep clean to prevent overheating. Remove the starter cover, clean openings with a wooden scraper and brush. Scrape dirt from cylinder head cooling fins. Clean flywheel vanes.

- Muffler or Spark Arrester and Exhaust Port: Periodically remove, clean, and inspect the spark arrester/muffler. Remove carbon deposits with a scraper blade or wire brush. Clean the exhaust port by pulling the starter rope to cover the piston, then using a wooden scraper. Blow loose particles away with compressed air (wear eye protection).

- Chain Brake: Keep the clutch drum and chain brake clean of sawdust. Inspect the brake band daily for wear. Replace if worn.

- Sprocket, Clutch, and Clutch Drum: Always install a new sprocket with a new chain. Replace damaged or worn sprockets. Do not operate with excessive clutch slippage. Keep clean of sawdust.

- Sprocket Replacement: Disconnect the spark plug wire, remove the spark plug, chain brake assembly, bar, chain, and starter housing. Lock the crankshaft, remove the clutch nut (clockwise), dust plate, and clutch. Remove and lubricate the sprocket and drum assembly and bearing. Install in reverse order, tightening the clutch nut counterclockwise.

- Automatic Oiler Adjustment: Adjusted at the factory for average conditions. Can be adjusted clockwise to reduce flow or counterclockwise to increase flow (1/4 turn at a time). Manual oiler can supplement for short periods.

- Guide Bar Maintenance:

- Bar Wear: Turn the bar over frequently for even wear.

- Bar Groove: Clean every time the chain is removed, using a depth gauge tang or similar instrument.

- Oil Passages: Clean periodically to ensure proper lubrication, using a depth gauge tang or small instrument. Check by observing oil spray when running the saw and pressing the manual oiler.

- Sprocket Tip Lubrication: Not always necessary for non-professional use, but recommended for professional use or under conditions like continuous cutting of dry/abrasive wood, boring cuts, cutting with the bar tip, or wet/snowy conditions. Lubricate after one hour of hard usage or three tanks of gas. Methods include needle nose grease gun (McCulloch Lubri-Gun P/N 68090 recommended), oil can, or oil soak.

- Chain Maintenance:

- Chain Tension: Check frequently. Keep snug but loose enough to be pulled by hand. If correct tension cannot be achieved, a link may need to be removed.

- New Chain Break-In: Run at low speed for 5 minutes (using manual oiler every 10-15 seconds), then shut off and adjust tension. Repeat after 10 minutes. Keep well lubricated.

- Chain Lubrication: Ensure manual and automatic oilers work. Keep the oil tank filled. Use plenty of oil, especially in abrasive wood.

- Chain Sharpening: Inspect regularly. Use a 5/32 inch (3.9 mm) round file and file guide for a 30° top filing angle. Apply pressure against the tooth face, pushing toward the outside of the tooth. Sharpen all teeth on one side, then the other, using the same number of strokes.

- Lowering Depth Gauges: Place a depth gauge tool over two cutter teeth. Remove the projecting part of the depth gauge with a flat file. Round off leading edges.

- Preventive Maintenance Check Chart: Provides a schedule for daily, weekly, monthly, and as-required inspections and maintenance for screws, nuts, bolts, controls, air filter, sawdust guard, chain, bar, shock mounts, sprocket, fuel filter, oil screen, muffler, spark plug, cylinder fins, starter rope, carburetor, fuel tank, breaker points, lamination gap, exhaust ports, fuel/oil/pressure hoses, carburetor diaphragm, and crankshaft seals.

- Storage: For short periods, keep the saw level with the fuel cap up. For storage over 30 days, drain the fuel tank, remove the spark plug and pour a teaspoon of oil into the combustion chamber, pull the starter rope several times, and replace the plug. Remove and clean the bar and chain, store the chain in oil, apply heavy oil film to the bar, and cover the saw. Store in a dry place away from ignition sources. Ideally, operate for 5 minutes every 30 days.

- Removal from Storage: Remove the spark plug, pull the starter rope, clean/gap or replace the spark plug. Fill the fuel tank with the correct mixture and the chain oil tank.

- Easier Starting Hint (for new or long-stored saws): Remove the air filter cover and air filter. Inject about half a teaspoon of fuel mixture into the carburetor air intake. Pull the starter rope two or three times. Stop the engine and replace the air filter and cover once it runs on its own fuel system. This method is not for regular starting.

Accessories:

- Spark Arrester Screens: Available from McCulloch dealers for installation on the muffler, required by some local regulations.

- Spike Kit: Wood grippers and fulcrum points for cutting control, available from McCulloch dealers.