13

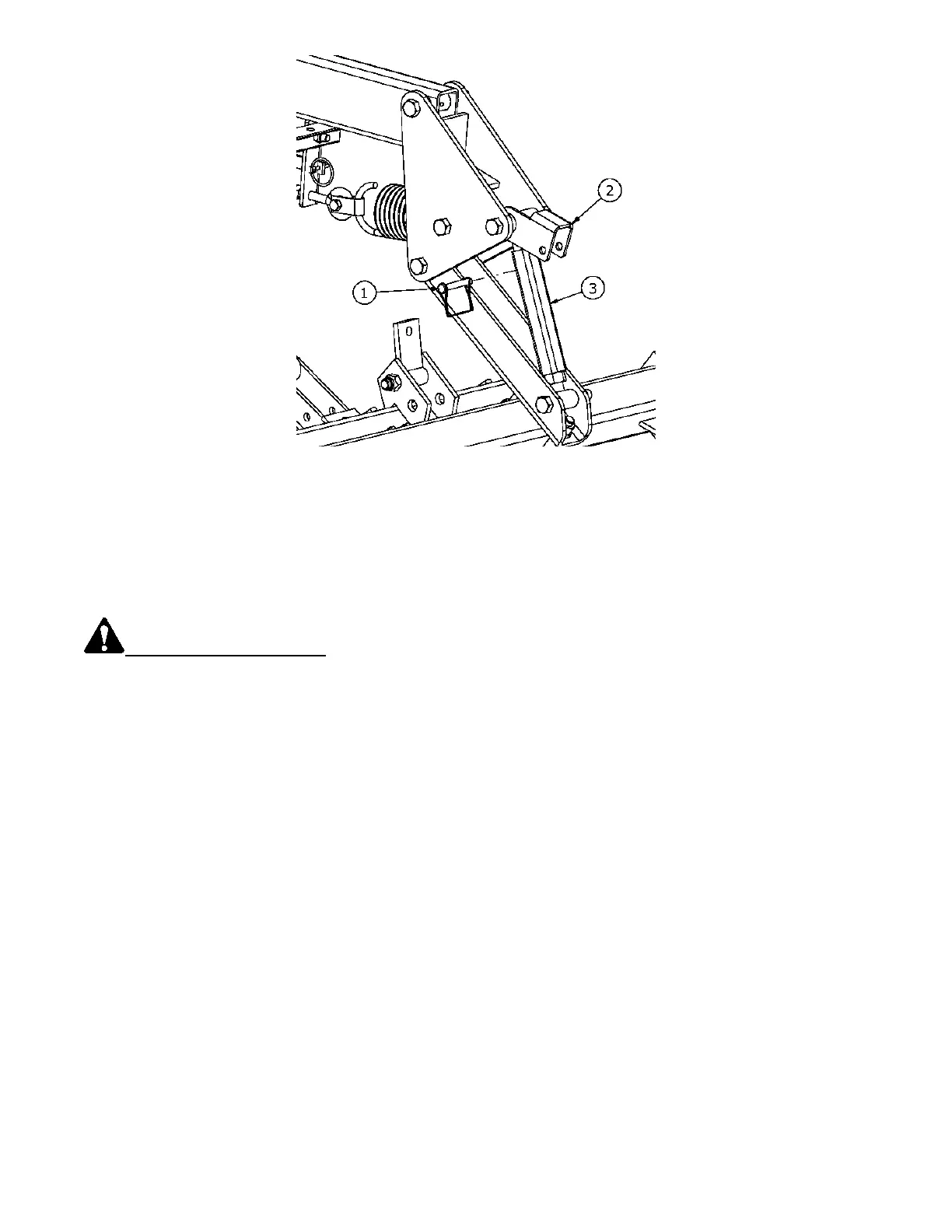

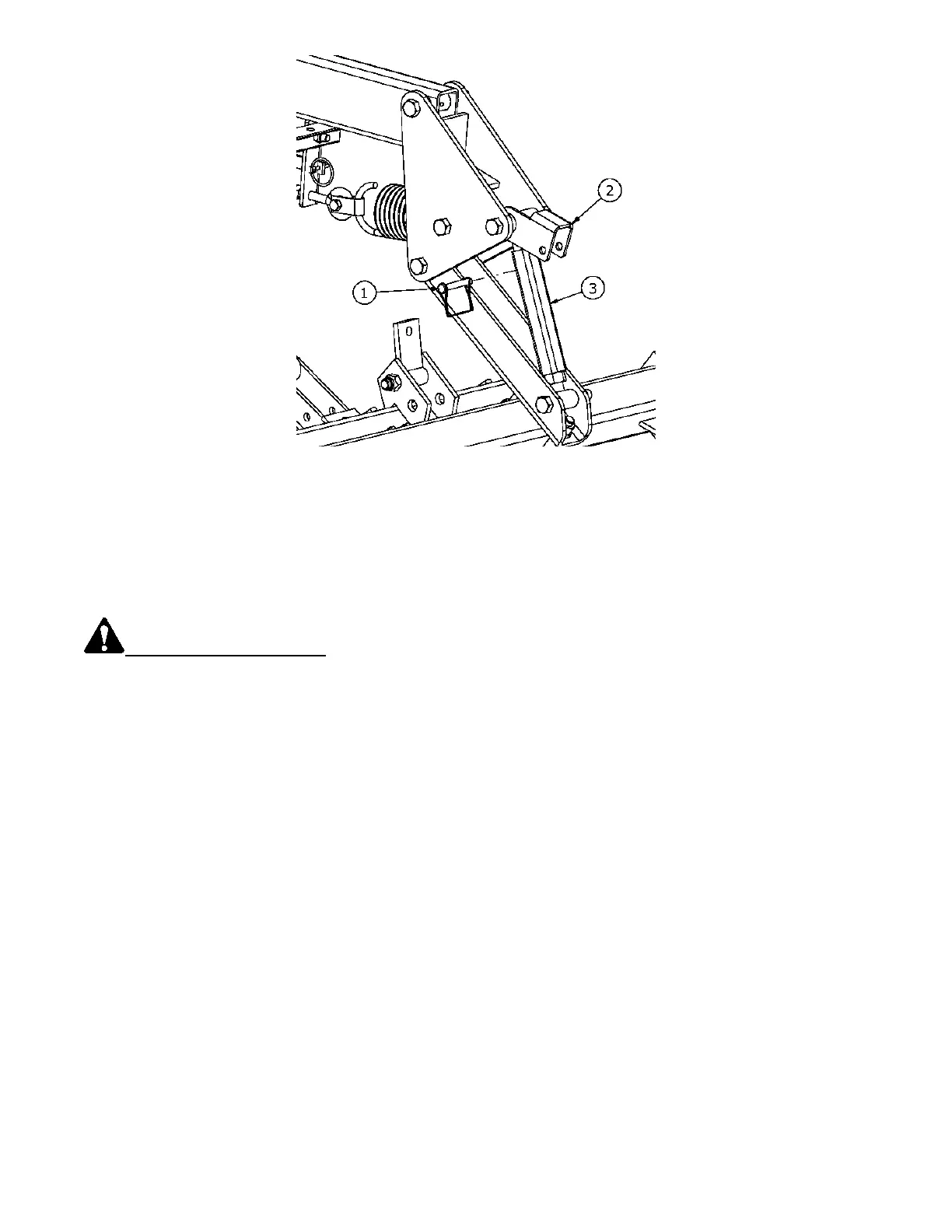

Figure 7

* Adjust the spring tension just tight enough to prevent it from loosening and falling out when in the

raised position. Set the rolling basket height by lowering the unit onto a flat surface and adjusting the

basket to just touch the ground. During operation the spring should only lightly stretch, approximately

1/16” gap between the spring coils. Too much spring tension will cause premature failure, especially

when going through waterways or ditches.

Performing Maintenance:

Good maintenance is your responsibility. Poor maintenance is an invitation to trouble.

Before working on this machine, stop the tractor or towing vehicle, set the brakes, lower into field

position, relieve the hydraulic fluid pressure, shut off the engine and remove the ignition keys.

Always use safety support and block the wheels. When performing maintenance, never use a jack to

support the machine. Assist the jack with blocks or other adequate support.

Use extreme caution when making adjustments.

When disconnecting hydraulic lines, shut off hydraulic supply and relieve all pressure.

Never use hands to locate a hydraulic leak on attachments. Use a piece of cardboard or wood.

Hydraulic fluid escaping under pressure can penetrate the skin.

Openings in the skin and minor cuts are susceptible to infection from hydraulic fluid. If injured by

escaping hydraulic fluid, see a doctor at once. Gangrene can result. Without immediate medical

treatment, serious infection and reactions can occur.

When installing, replacing, or repairing hydraulic system cylinders or parts, make sure that the entire

system is charged and free of air before resuming operations. Failure to bleed the system of all air can

result in improper machine operation, causing severe injury.

After servicing, be sure all tools, parts, and service equipment are removed.

Never replace hex bolts with less than grade five bolts unless otherwise specified.

Loading...

Loading...