108

GUIDELINES OF FIELD-CHARGING AIR CONDITIONING SYSTEMS WITH SCROLL

COMPRESSORS

These guidelines are intended for use with Scroll compressors only with R22, R407C, R134a, R404A, R507,

and R410A refrigerants. They do not apply to reciprocating compressors or competitive Scroll compressors.

FIELD-CHARGING – SOME PRECAUTION POINTS

Scroll compressors have a very high volumetric efficiency and quickly pump a deep vacuum if there is

insufficient refrigerant in the system or if refrigerant is added too slowly. Operation with low suction pressure

will quickly lead to very high discharge temperatures. While this process is happening, the scrolls are not

being well lubricated – scrolls depend on the oil mist in the refrigerant for lubrication. A lack of lubrication

leads to high friction between the scroll flanks and tips and generates additional heat. The combination of

heat of compression and heat from increased friction is concentrated in a small localized discharge area

where temperatures can quickly rise to more than 300°C. These extreme temperatures damage the Scroll

spirals and the orbiting Scroll bearing. This damage can occur in less than one minute especially on larger

compressors. Failure may occur in the first few hours or the damage done during field charging may show up

some time later.

Other typical field charging problems include undercharging, overcharging, moisture or air in the system etc.

In time each one of these problems can cause compressor failure.

EQUIPMENT

Minimal equipment is required for field charging. The minimum equipment required to do a satisfactory job

is:-

Set of service gauges

Hoses

Vacuum pump

Vacuum gauge

Scales

Thermometer

CHARGING HOSES

Most field-charging is done using standard service hoses. Hoses are made in different colors with different

working pressures and with different leak rates but the most important point is the presence or absence of

Shredder valve depressors. Shredder valve depressors severely restrict the flow through the service hoses.

This slows evacuation and vapor charging dramatically. In most cases the Shredder depressor can be

removed but it is simpler to have one set of hoses with and one set without Shredder depressors.

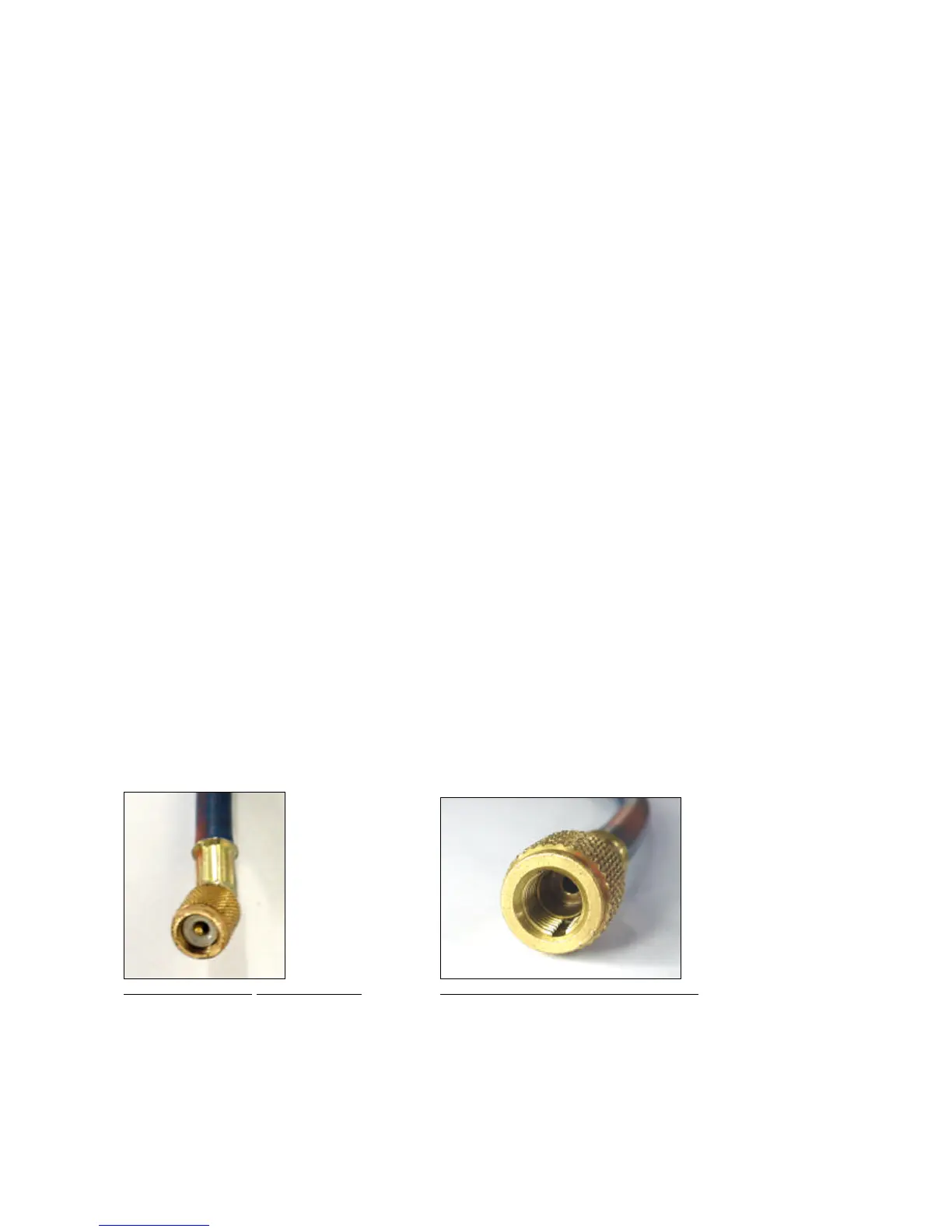

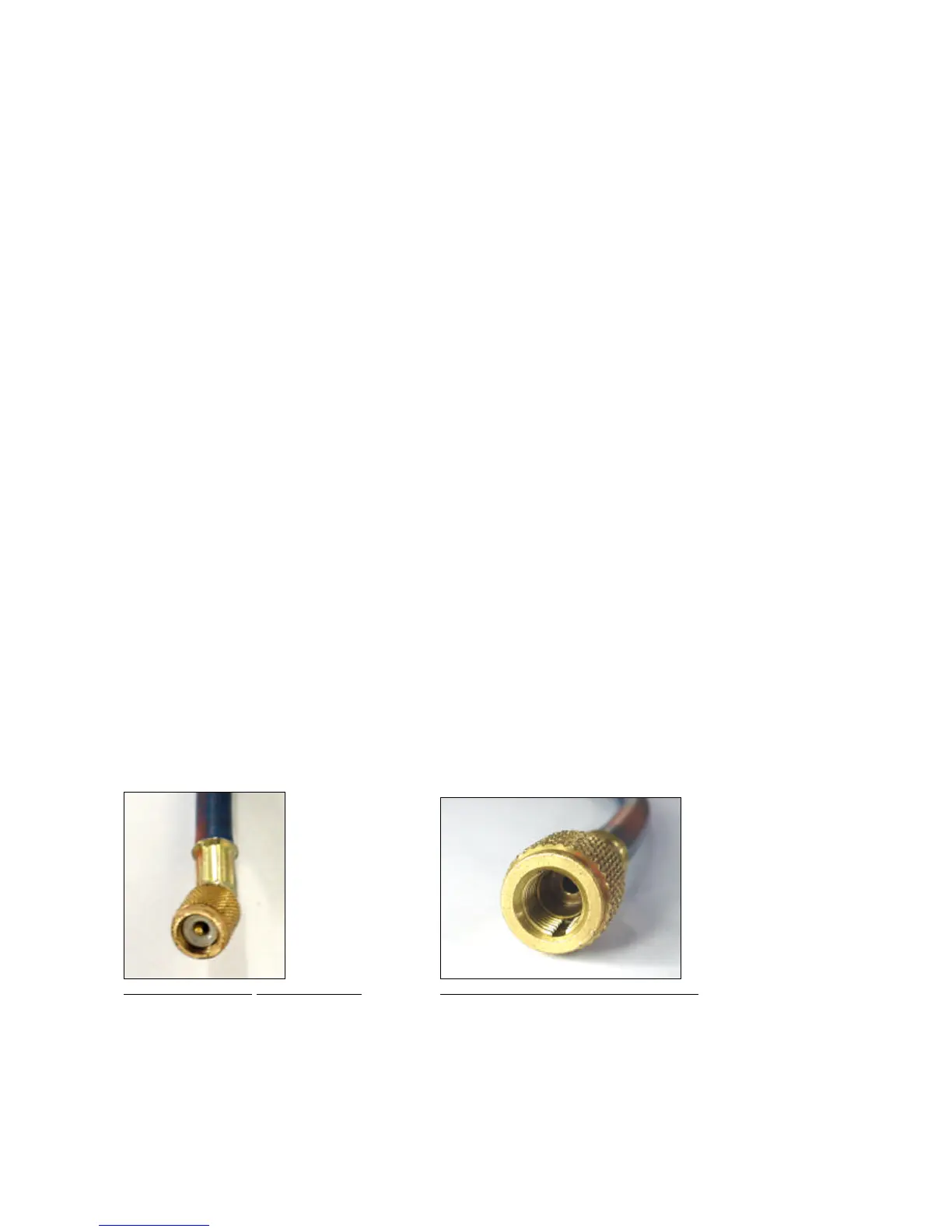

Hose with Shredder valve Depressor Hose without Shredder valve Depressor

Hose selection is important depending whether the system is being evacuated or charged. Charging liquid

from the cylinder into the liquid line should be carried out using an open hose connected to an unrestricted

fitting. This will reduce charging time.

Typical service valves found on the

Shredder Valves

Loading...

Loading...