Operating instructions Glass-, utensil- and dishwasher

M-iClean U

9763258 21 / 72

Design and construction subject to change without prior notice!

5.6 Dosing equipment

Reduced durability of dosing units and other dishwasher components

The use of inappropriate detergent and rinse aid can corrode the dosing units and

other machine components.

• If necessary: Consult with MEIKO and the detergent supplier.

Detergent dosing

The detergent dosing unit is designed to automatically add liquid alkaline deter-

gent to the dishwashing machine (the manual addition of detergent products is not

recommended).

The detergent is transported from the storage container to the wash tank via a

hose conduit. The dosing equipment is self-priming. Dosing occurs during each fill-

ing cycle and at the beginning of each program cycle via timer control.

Normally, a dosing of approx. 2 ml of detergent per litre of tank water is the correct

concentration. This may, however, be increased up to 5 ml/l or reduced to 1 ml/l

depending on the water quality, the type of items being washed and how dirty they

are.

Rinse aid dosing

The rinse aid dosing unit is designed to automatically admix liquid final rinse aid

into the fresh water.

The rinse aid is pumped out of the storage container into the fresh water supply

line through a hose conduit. The dosing equipment is self-priming. Dosing takes

place during each filling cycle.

The correct dosage leads to an even water film.

In case of overdosing, bubbles and stripes will form, which means that the dosage

needs to be reduced.

In case of under-dosing, water drops remain on the wash which means that the

dosage needs to be increased.

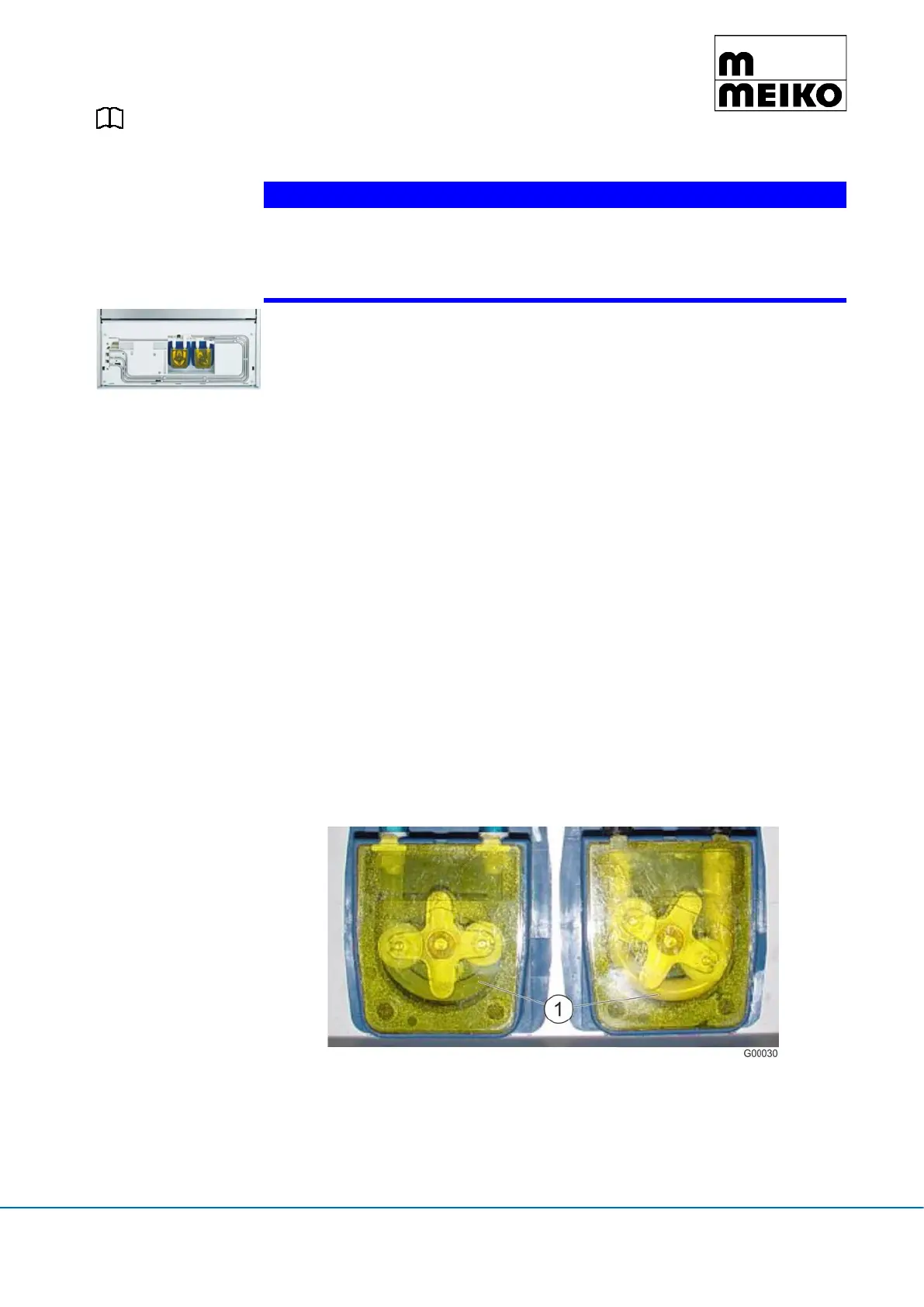

Dosing equipment lifetime

The lifetime of dosing equipment and its components depends on the chemicals

used.

The peristaltic tubes (1) are wear and tear parts whose longevity depends heavily on

the chemicals used and on the duration of use. If required these must be replaced.

Loading...

Loading...