ENGINES - 3A-7190-823225--1 1096

72386

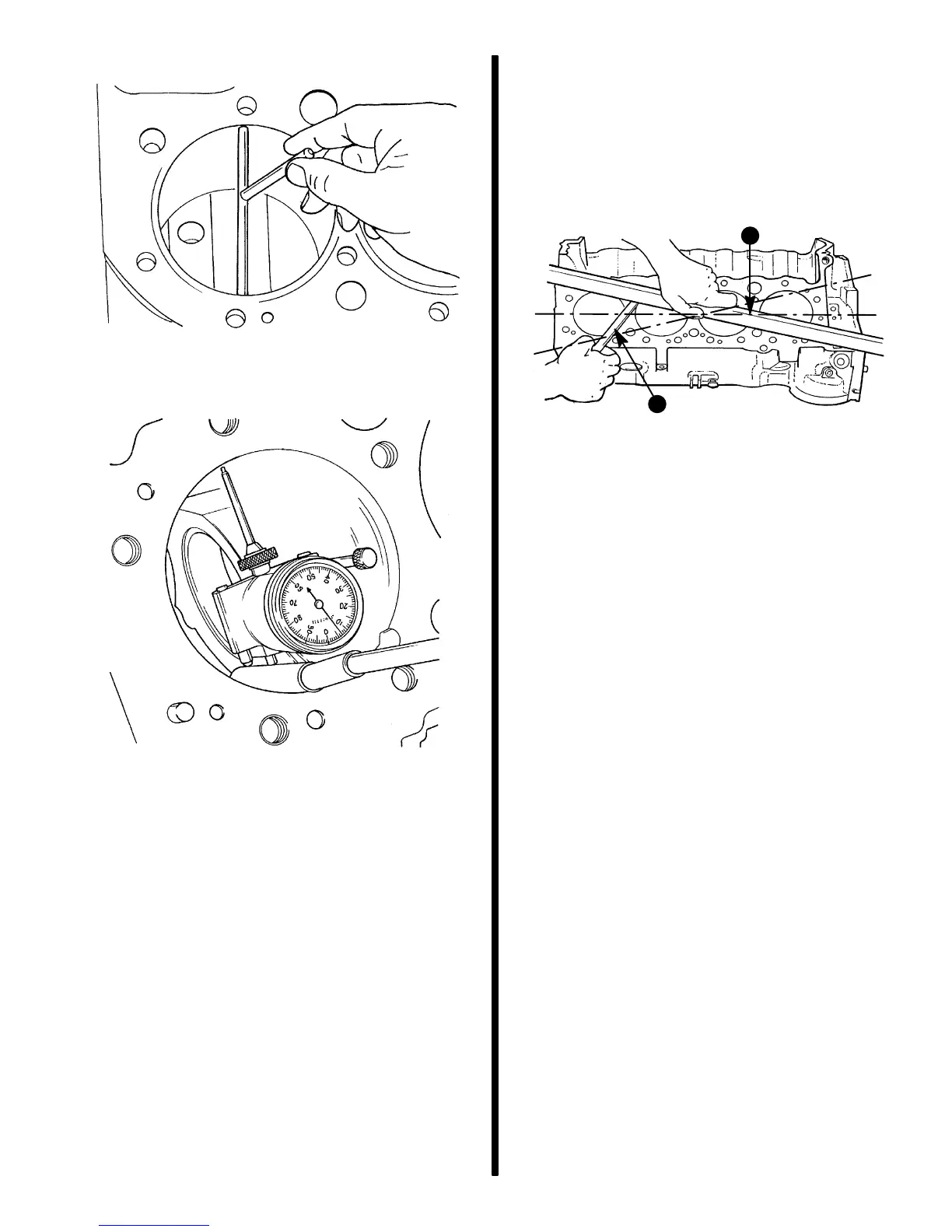

Measuring Cylinder Bore

72387

Measuring Cylinder Bore

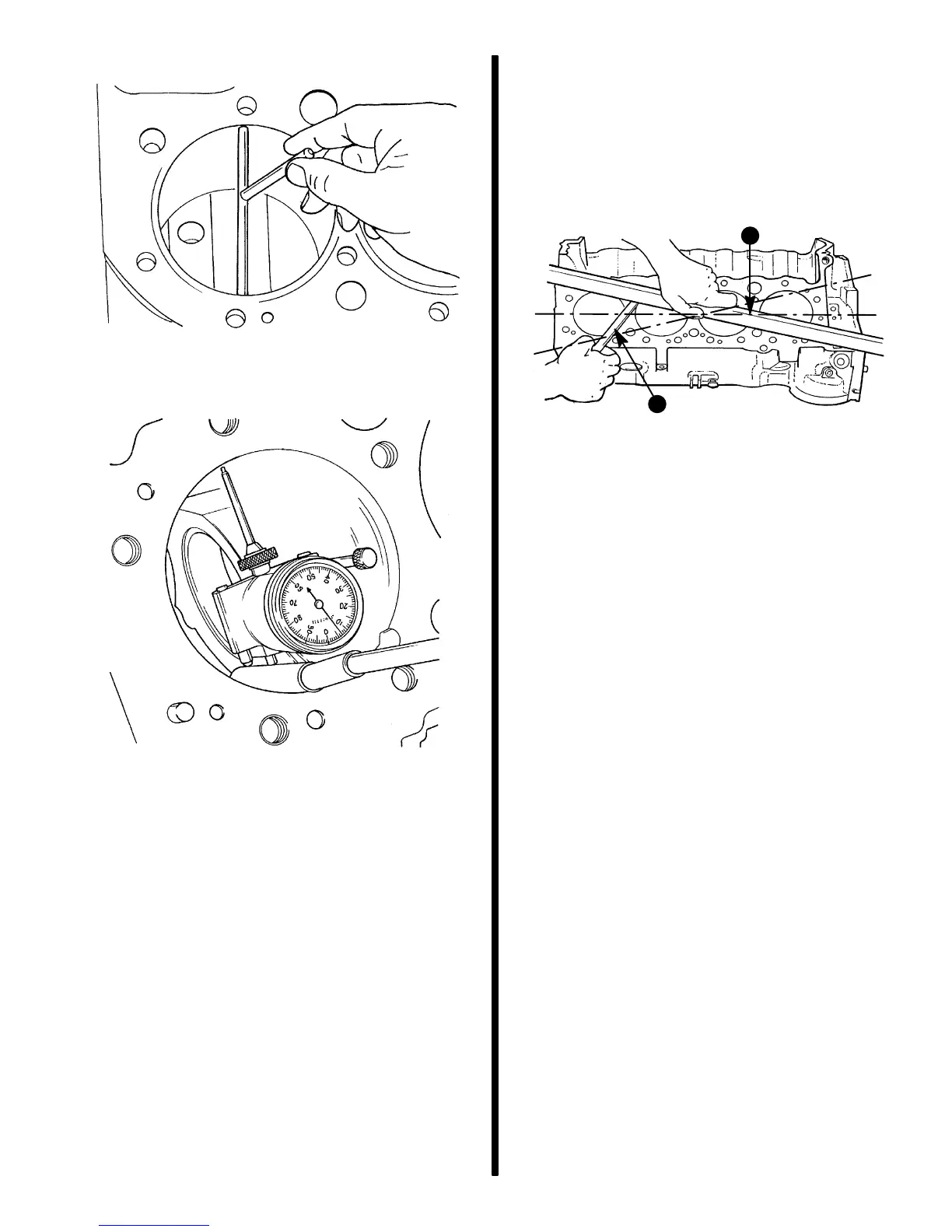

8. Check cylinder head gasket surfaces for war-

page with a machinist’s straight-edge and a feel-

er gauge, as shown. Take measurements diago-

nally across surfaces (both ways) and straight

down center. If surfaces are warped more than

.003 in. (0.07 mm) in a 6 in. area or .007 in. (0.2

mm) overall, block must be resurfaced by an au-

tomotive machine shop.

72388

a - Machinist’s Straight-Edge

b - Feeler Gauge

b

a

CYLINDER CONDITIONING

1. Performance of the following operation depends

upon engine condition at time of repair.

2. If cylinder block inspection indicates that block is

suitable for continued use (except for

out-of-round or tapered cylinders), they can be

conditioned by honing or boring.

3. If cylinders have less than .005 in. (0.127 mm) ta-

per or wear, they can be conditioned with a hone

and fitted with high limit standard size piston. A

cylinder bore of more than .005 in. wear or taper

may not clean up entirely when fitted to a high lim-

it piston. To entirely clean up the bore, it will be

necessary to rebore for an oversize piston. If

more than .005 in. taper or wear, bore and hone

to smallest oversize that will permit complete re-

surfacing of all cylinders.

4. When pistons are being fitted and honing is not

necessary, cylinder bores may be cleaned with a

hot water and detergent wash. After cleaning,

swab cylinder bores several times with light en-

gine oil and a clean cloth, then wipe with a clean

dry cloth.

Loading...

Loading...