OM-286504 Page 64

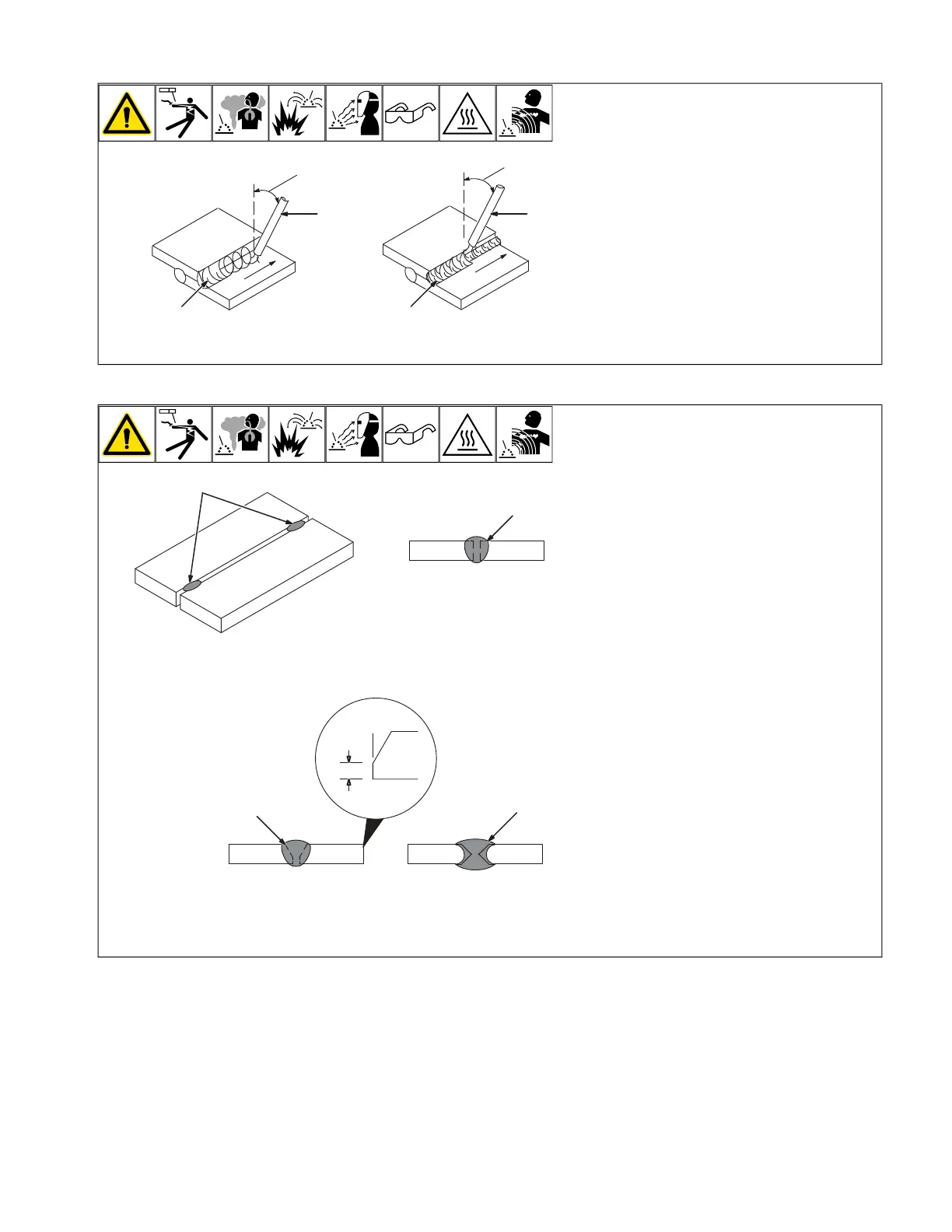

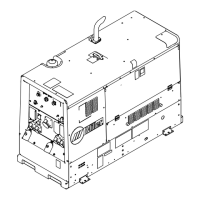

12-9. Welding Lap Joints

1-1. Welding Lap Joints

≤ 30

°

≤ 30

°

1

1

2

3

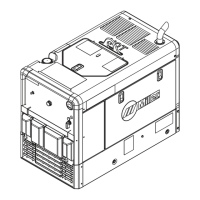

1-2. Welding Groove (Butt) Joints

30

°

2

1

1/16 in.

(1.6 mm)

3

4

1-3. Welding T-Joints

≤ 45

°

1

2

1

3

2

1-4. Weld Test

2 3 in.

1/4 in.

3

2

1

2 3 in.

3

2

1

(51-76 mm)

(6.4 mm)

(51-76 mm)

1 Electrode

2 Single-Layer Fillet Weld

Move electrode in circular motion.

3 Multi-Layer Fillet Weld

Weld a second layer when a heavier fillet is

needed. Remove slag before making anoth-

er weld pass. Weld both sides of joint for

maximum strength.

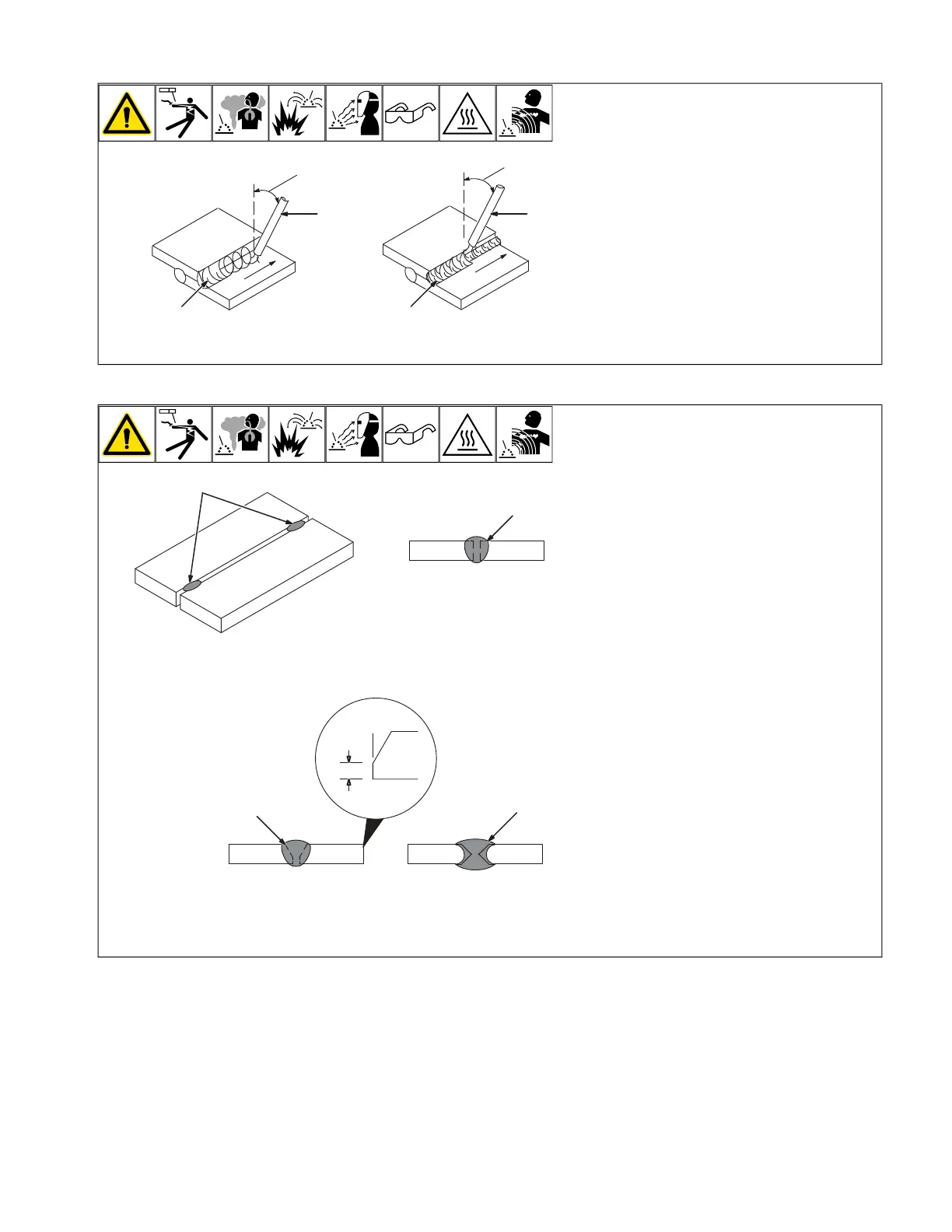

12-10. Welding Groove (Butt) Joints

1-1. Welding Lap Joints

≤ 30

°

≤ 30

°

1

1

2

3

1-2. Welding Groove (Butt) Joints

30

°

2

1

1/16 in.

(1.6 mm)

3

4

1-3. Welding T-Joints

≤ 45

°

1

2

1

3

2

1-4. Weld Test

2 3 in.

1/4 in.

3

2

1

2 3 in.

3

2

1

(51-76 mm)

(6.4 mm)

(51-76 mm)

1 Tack Welds

Prevent butt joint distortion by tack welding

the materials in position before final weld.

Workpiece distortion occurs when heat is ap-

plied locally to a joint. One side of a metal

plate will curl up toward the weld. Distortion

will also cause the edges of a butt joint to pull

together ahead of the electrode as the weld

cools.

2 Square Groove Weld

3 Single V-Groove Weld

4 Double V-Groove Weld

Materials up to 3/16 in. (5 mm) thick can

often be welded without special preparation

using the square groove weld. However,

when welding thicker materials it may be

necessary to prepare the edges (V-groove)

of butt joints to ensure good welds.

The single or double V-groove weld is good

for materials 3/16 - 3/4 in. (5-19 mm) thick.

Generally, the single V-groove is used on

materials up to 3/4 in. (19 mm) thick and

when, regardless of thickness, you can weld

from one side only. Create a 30 degree bevel

with oxyacetylene or plasma cutting equip-

ment. Remove scale from material after cut-

ting. A grinder can also be used to prepare

bevels.

Loading...

Loading...