Calibration

The calibration is an operation that matches the

actual load of the sensor to the display of

CSD-709 to display the electrical signal from the

sensor (load cell) as an accurate load.

Status display LED

SEL1 SEL2

Calibration

number

0

1

2

3

tatus displa

EL

EL

umber

For detailed information,

refer to the instruction manual which can be found on our website.

Reference

For detailed information,

refer to the instruction manual which can be found on our website.

Reference

(8) Press the [***] key twice to return to the measurement mode.

The display shows [xxx] and then the measurement mode returns.

(7) Press the [***] key to confirm the detection zone.

The display shows [xxx] .

(8) Press the [***] key twice to return to the measurement mode.

The display shows [xxx] and then the measurement mode returns.

(7) After displaying, press the [***] key. [xxx] appears.

(6) Display the detection operation number using [***] and [***] keys.

(1) Press the [***] key four timesto display [xxx] .

(1) Press the [***] key five times to display [xxx] .

(3) Press the [***] key to complete the check of external control input.

(4) Press the [***] key twice to return to the measurement mode.

(4) Press the [***] key to complete the check of external control output.

(5) Press the [***] key twice to return to the measurement mode.

(2) When the [***] key is pressed after displaying, [xxx] blinks and

the LED “OUT1” at the status display turns on.

(3) Using the [***] and [***] keys, turn on the followingLEDs to turn on

the corresponding external control outputs.

(1) Press the [***] key six times to display [xxx] .

(5) Press the [***] key twice to return to the measurement mode.

(4) Press the [***] key to complete the check of analog output.

(5) Press the [***] key twice

to return to the measurement mode.

(4) Press the [***] key to complete the check of BCD output.

(2) After displaying, press the [***] key.

As shown in the tables, the display varies

depending on the mounted card and output value.

(1) Press the [***] key six times to display [xxx] .

(2) After displaying, press the [***] key. [xxx] appears.

* “0” on the first digit blinks.

(3) Change the current or voltage value to be output.

: Change the sign

: Change the display.

(3) Change the digit of blinking “0”.

: Blinking digit moves toward the smallest digit.

: Blinking digit moves toward the largest digit.

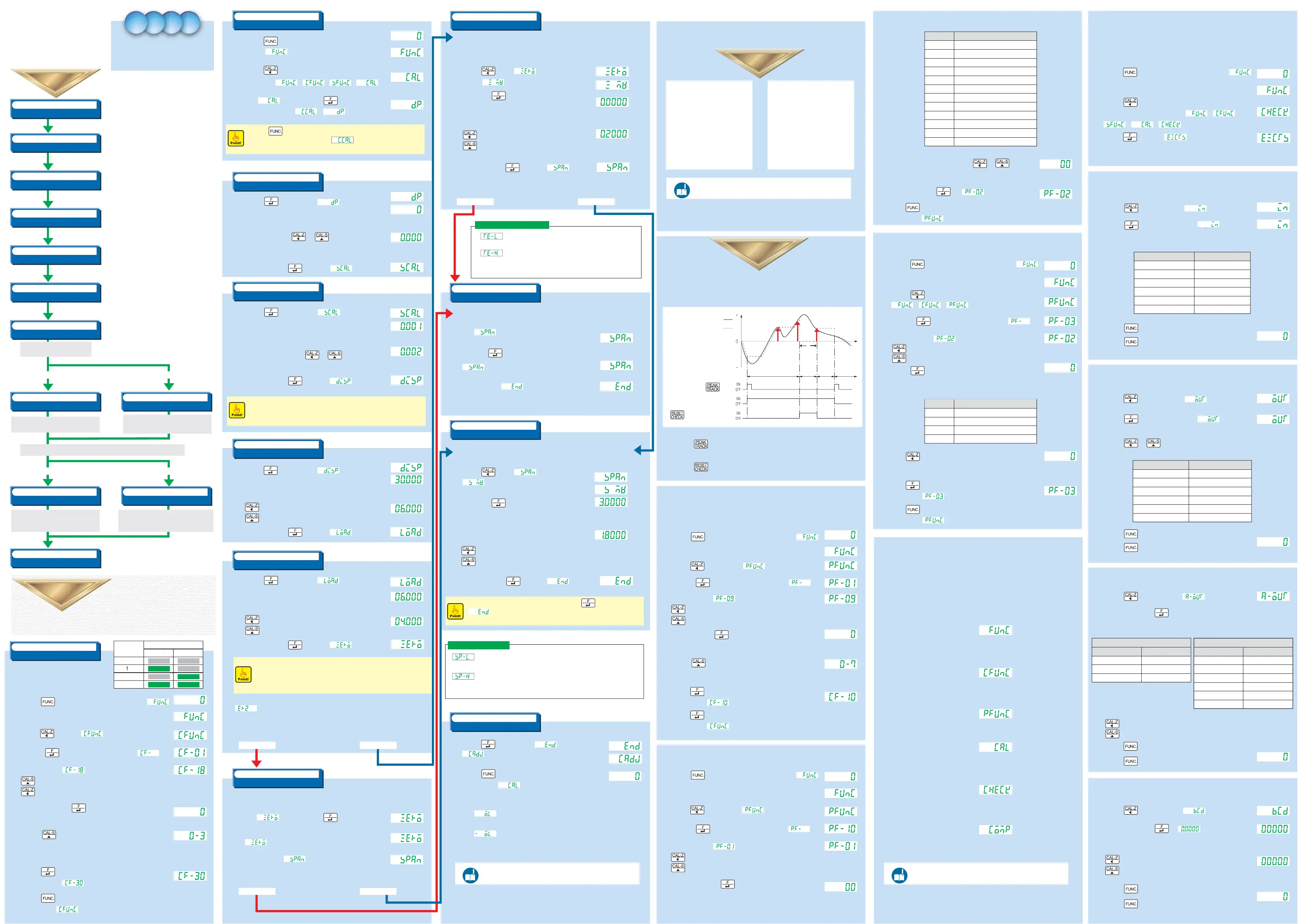

(1)

(2)

(3)

(4)

(5)

(6)

Selecting Calibration Number

Switching to Calibration Mode

Set of Decimal Point Position

Set of Minimum Scale

Set of Rated Capacity

Set of Actual Load

Zero Calibration (Actual Load)

Zero Calibration (Numerical Input)

Input a power of 100 VAC to 240 VAC and frequency of

50/60 Hz (or 12 VDC to 24 VDC) and energize CSD-709 for

ten minutes or so to stabilize CSD-709 and measuring part

(load cell).

CSD-709 can retain four patterns of calibration result.

Select a calibration number to calibrate.

Switch from measurement mode to calibration mode.

Set the decimal point display position.

Setting range: [0 (None)], [0.0], [0.00], [0.000], and [0.0000]

Set the minimum scale (minimum unit for measurement).

Setting range: [1], [2], [5], and [10]

Set the rated capacity (maximum load that can be

measured).

Set the load actually applied in span calibration.

To minimize calibration error, use a load at least two-thirds

of the rated capacity.

If a load cannot be applied, input the same value as the rated

capacity.

Is it possible to create no-load state

(initial state)?

Yes No

Yes No

(7) (7)

Read a load cell output value in no-load state

and register a zero point.

When no-load state (initial state) cannot be created,

register the output [mV/V] equivalent to no-load

state by numerical input.

Is it possible to apply a load two-thirds or more of the rated capacity?

(8) (8)

Span Calibration (Actual Load)

Span Calibration (Numerical Input)

Read a load cell output value while the load set

according to (6) Set of Actual Load is applied

and register a span point.

Register a span point [mV/V] obtained by subtracting the output

[mV/V] equivalent to no-load state from the output [mV/V] equivalent

to the load equal to the rated capacity by numerical input.

(9)

End of Calibration

Exit the calibration mode.

Calibration with actual load assumes

Calibration with actual load assumes a rated capacity

of 6.000 kg in the state where a load of 4 kg can be

applied and a minimum scale of 0.002 kg.

Calibration with numerical input assumes

Calibration with numerical input assumes 0.2 mV/V as

the output equivalent to no-load state (initial state) and

2 mV/V as the output equivalent to the rated capacity.

This unit can retain calibration results using four

calibration numbers: 0 to 3.

The LED ON/OFF state at the status display

indicates the current calibration number.

Yes No

(8)

Span Calibration (Actual Load)

(8)

Span Calibration (Numerical Input)

(9)

End of Calibration

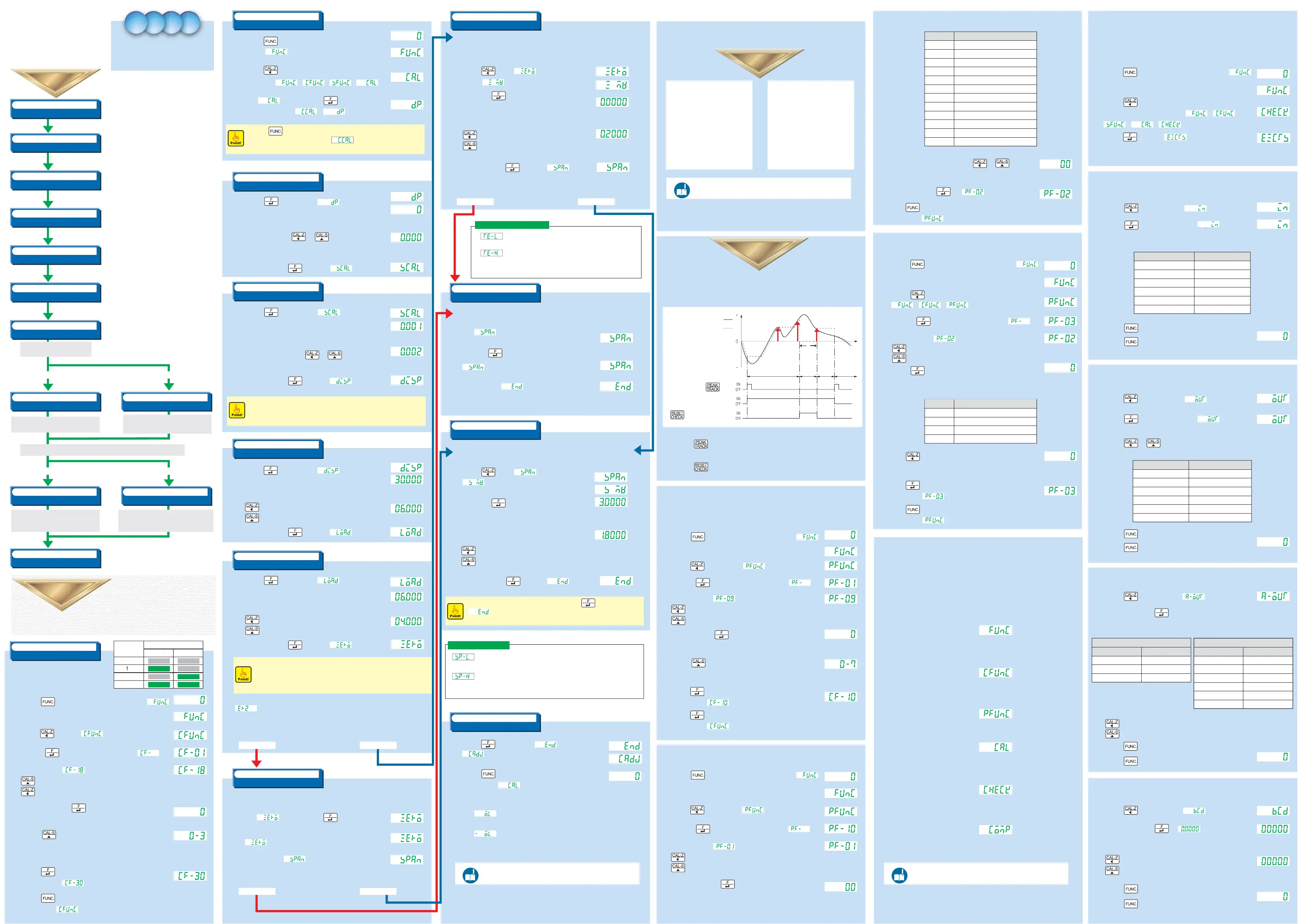

- Peak hold

- Bottom hold

- Peak/bottom hold

- Peak-to-peak hold

- Maximum value hold

- Minimum value hold

- Maximum-minimum difference hold

- Average value hold

- 4-inflection points hold

- All zones

- Specified zone

- Time specified zone

- Automatic start time specified zone

Detection operation: Peak hold (hold a detected maximum load)

Detection zone: All zones The following describes the case using above conditions.

(1) Selecting Detection Condition Number

(1) Selecting Detection Condition Number

(3) Setting Detection Zone

(3) Setting Detection Zone

● Checking External Control Input

● Checking External Control Input

● Checking External Control Output

● Checking External Control Output

● Checking Analog Output

● Checking BCD Output

(2) Setting Detection Operation

(2) Setting Detection Operation

http://www.minebea-mcd.com/en/

product/i-amp/csd709.html

http://www.minebea-mcd.com/en/

product/i-amp/csd709.html

* As an example,

[00] is selected to set the detection operation to peak hold.

This unit allows the user to check various items via check mode.

(6) Press the [***] key and

select the number corresponding to desired detection zone

* As an example, [0] is selected to set the detection zone to all zones.

* To prevent the zero point from exceeding the adjustment range,

check the rated capacity of load cell, initial state, etc.

This blinks for about two seconds when the load cell output exceeds

the zero adjustment range of negative side(-2.5 mV/V or less).

This blinks for about two seconds when the load cell output exceeds

the zero adjustment range of positive side(2.5 mV/V or more).

Zero calibration error display

Yes No

Yes No

http://www.minebea-mcd.com/en/

product/i-amp/csd709.html

For detailed information,

refer to the instruction manual which can be found on our website.

Reference

(2) When the [***] key is pressed after displaying, [xxx] blinks and

the LED corresponding to the external control input turns on.

(3) Press the [***] key to display [xxx] .

(2) Press the [***] key four times.

The display changes in the following order: [xxx] -> [xxx] ->

[xxx] -> [xxx] -> [xxx] .

(1) Press the [***] key in the normal measurement mode to display [xxx] .

(4) Change the display to [xxx] .

: Select a digit to change.

: Change the value of the selected digit.

(3) Pressing the [***] key displays a two-digit number following [xxx] .

(2) Press the [***] key twice. The display changes in the following order:

[xxx] -> [xxx] -> [xxx] .

(8) Press the [***] key twice to return to the measurement mode.

The display shows [xxx] and then the measurement mode returns.

(7) Press the [***] key to confirm the detection condition number.

The display shows [xxx] .

(6) Press the [***] key to select a detection condition number you want to save.

A calibration number changes in the following order: [0] -> [1] -> [2] ... [7].

(5) After setting, press the [***] key.

The current detection condition number (0 to 7) will be displayed.

(4) Change the display to [xxx] .

: Select a digit to change.

: Change the value of the selected digit.

(3) Pressing the [***] key displays a two-digit number following [xxx] .

(2) Press the [***] key twice to display [xxx] .

(1) Press the [***] key in the normal measurement mode to display [xxx] .

(2) Press the [***] key twice to return to the measurement mode.

The display shows [CAL] and then the measurement mode returns.

(4) After setting, press the [***] key to display [End] .

(2) Then press the [***] key to display the stored load cell output

value.

(1) Press the [***] key while [xxx] is displayed to display

[ .

(3) Set a value obtained by subtracting the output value equivalent

to the zero point of load cell from the load cell output

value equivalent to the set rated capacity in mV/V.

: Select a digit to change.

: Change the value of the selected digit.

(3) When reading ends, [xxx] appears.

(2) [xxx] starts blinking and reading starts.

(1) While [xxx] is displayed,

apply the load set according to (6) Setting Actual Load

and press the [***] key

(4) After setting, press the [***] key to display [xxx] .

(3) Set the output value equivalent to no-load state in mV/V.

: Select a digit to change.

: Change the value of the selected digit.

(1) Press the [***] key while [Zero] is displayed

to display [xxx] .

(3) When reading ends, [xxx] appears.

(2) [xxx] starts blinking and reading starts.

(1) While [xxx] is displayed, press the [***] key

without applying a load.

Error display in rated capacity/actual load setting

This blinks for about two seconds when you set a value meeting [Rated capacity] < [Actual load].

* Correct settings so that “Rated capacity ≥ Actual load” is met.

(2) Set the actual load value.

: Select a digit to change.

: Change the value of the selected digit.

(1) When the [***] key is pressed while [xxx] is displayed,

the currently stored actual load is displayed.

(3) After setting, press the [***] key to display [xxx] .

(2) Set the rated capacity.

: Select a digit to change.

: Change the value of the selected digit.

(2) Set the minimum scale.

Select the minimum scale using [***] and [***] keys.

The last two digits change as follows: [01], [02], [05], and [10].

(1) When the [***] key is pressed while [xxx] is displayed,

the currently stored minimum scale is displayed.

(2) Set the position of decimal point.

Select the position using [***] and [***] keys.

The position of decimal point can be selected from [0 (None)], [0.0], [0.00],

[0.000], and [0.0000].

(1) When the [***] key is pressed while [xxx] is displayed,

a decimal point is displayed at the currently stored position.

(2) Press the [***] key three times. The display changes in the

following order: [xxx] -> [xxx] -> [xxx] -> [xxx] .

(7) Press the [***] key to confirm the calibration number.

The display becomes [xxx] .

(2) Press the [***] key to display [xxx] .

(3) Pressing the [***] key displays a two-digit number following [xxx] .

(2) Press the [***] key twice to display [xxx] .

Select an item to check from the following items and take the procedure.

ON: Detects and displays a peak value. (Detection zone (1))

OFF: Displays the current load. (Load display zone)

Used to check the following items.

- Comparison value setting contents

- Setting contents related to the comparator, etc.

COMP selection mode

External control input LED name

INPUT1 turns ON

INPUT2 turns ON

INPUT3 turns ON

INPUT4 turns ON

INPUT5 turns ON

INPUT6 turns ON

SEL1

SEL2

CHECK

HOLD

PEAK

MEAS.

External control outputLED name

OUT1

OUT2

OUT3

OUT4

SEL1

SEL2

OUTPUT1 turns ON

OUTPUT2 turns ON

OUTPUT3 turns ON

OUTPUT4 turns ON

OUTPUT5 turns ON

OUTPUT6 turns ON

Current output card

DisplayOutput value

4 mA

12 mA

20 mA

LOW

MID

HI

Voltage output card

DisplayOutput value

0 V

5 V

10 V

0 V

-5 V

-10 V

LOW

MID

HI

-LOW

-MID

-HI

Blinks

Blinks

(Measurement mode)

(Measurement mode)

(Measurement mode)

Blinks

Calibration

Procedure

Calibration

Procedure

Calibration

Procedure

Energizing power supply

Advanced preparation

Selecting Calibration Number

(1)

(1) Press the [***] key in the normal measurement mode to display [xxx] .

(Measurement mode)

Proceed to step

(2)

(2)

Switching to Calibration Mode

(3)

Setting Decimal Point Position

(4)

Setting Minimum Scale

(5)

Setting Rated Capacity

(6)

Setting Actual Load

(7)

Zero Calibration (Actual Load)

(1) Press the [***] key in the normal measurement mode

to display [xxx] .

(Measurement mode)

(3) When [CAL] is displayed, press the [***] key twice.

The display changes from [xxx] to [xxx] .

■

When the [***] key is pressed after taking the steps in (2) Switching to Calibration Mode,

the previous set value will be canceled and [xxx] will return on the display.

When you cancel the process halfway, the set value will not be saved.

Stored position

Set position

(3) After setting, press the [***] key to display [xx] .

Stored position

Set position

(3) After setting, press the [***] key to display [xxx] .

Example of display change caused by minimum scale setting

■

With the minimum scale set to [02], the load display changes as follows: [0.002] -> [0.004]

-> [0.006] (decimal point set to [0.000]).

(1) When the [***] key is pressed while [xxx] is displayed,

the currently stored rated capacity is displayed.

Stored rated capacity

Set rated capacity

Stored actual load

Set actual load

kg

kg

kg

kg

(3) After setting, press the [***] key to display [xxx] .

■

Set the actual load value used for calibration to a value at least two-thirds of the rated capacity.

■

When the load which is the same as the rated capacity can be applied, set the actual load

equal to the rated capacity.

■

When span calibration is performed with numerical input according to (8) Span Calibration

(Numerical Input), set the actual load equal to the rated capacity.

Proceed to zero calibration.

Is it possible to create no-load state (initial state)?

Read a load cell output value in no-load state (initial state) and

register a zero point.

Blinks

Proceed to span calibration.

Is it possible to apply a load two-thirds or more of the rated capacity?

(7)

Zero Calibration (Numerical Input)

Proceed to

(9)

(Measurement mode)

Only when CSD-709 in use is replaced with another CSD-709 and also

all the following conditions are met, zero calibration is performed with numerical input.

- Zero calibration data (mV/V value) obtained before replacement remains.

- No-load state (initial state) cannot be created.

(2) Then press the [***] key to display the stored load cell output value.

Stored load cell output value

Set load cell output value

mV/V

mV/V

Proceed to span calibration.

Is it possible to apply a load two-thirds or more of the rated capacity?

Read a load cell output value while the actual load set according to

(6) Setting Actual Load is applied and register a span point.

Blinks

■

A set value remains in provisionally-registered state until the [***] key is pressed with

[xxx] displayed to confirm the value. When you cancel the process halfway,

the set value will not be saved.

Register a span point by inputting a value obtained by subtracting the load cell output value at

the zero point from the load cell output value expected when the load equal to the rated

capacity is applied.

Stored load cell output value

Set load cell output value

mV/V

mV/V

(1) When the [***] key is pressed while [End] is displayed,

[xxx] appears and the set data is stored in the internal memory.

Measurement error display

* To display an overload error, any of the following conditions can be set.

When the load display

- falls below “(- Rated capacity) - 9 divisions”

- falls below “-110 % of rated capacity”

- falls below “-20 divisions”

When the load display

- exceeds “(+ Rated capacity) + 9 divisions”

- exceeds “+110 % of rated capacity”

Detection Types

Detailed Detection Procedure

Detailed Detection Procedure

Detection operation Detection zone

Actual load

Displayed value

Detection zone (1)

Time

Detection

zone (2)

RESET

zone

Load

display

zone

key

During peak detection

This unit can retain up to eight detection conditions using the detection condition numbers 0 to 7.

The following describes the setting procedure.

(Measurement mode)

Stored detection

condition number

Set detection

condition number

(1) Press the [***] key in the normal measurement mode to display [xxx] .

(Measurement mode)

* To prevent the span point from exceeding the adjustment range,

check the rated capacity of load cell, actual load, etc.

This blinks for about two seconds when the load cell output exceeds the span

adjustment range(larger than 3.1 mV/V).

This blinks for about two seconds when the load cell output falls short of the span

adjustment range(Load cell output voltage at span point - Load cell output voltage at

zero point ≤ 0.0 mV/V).

Span calibration error display

key or RESET input

ON: Displays 0. (RESET zone)

OFF: Resumes peak value detection. (Detection zone (2))

Detection operationNo.

00

01

02

03

04

05

06

07

08

09

10

11

Peak

Bottom

Peak/bottom

Peak-to-peak

Minimum value

Maximum value

Maximum-minimum difference

Inflection point A

Inflection point B

Inflection point C

Inflection point D

Average value

Detection operation numbers and corresponding detection operations

Detection zone numbers and corresponding detection zones

(Measurement mode)

Detection zoneNo.

0

1

2

3

All zones

Specified zone

Time specified zone

Automatic start time specified zone

The following modes are used to perform measurement or operate CSD-709.

Displays the current measurement value. The measurement mode is divided into two modes.

- Tracking mode: Displays an input value from measuring instrument which varies with time.

- Peak mode: Detects and retains a maximum/minimum point, etc. in measurement values.

Measurement mode

Allows the user to set the following functions or check the setting contents.

- Measurement function (AD sampling count, digital filter, etc.)

- Comparison function (comparator operation, etc.)

- Operation function (key lock, hold target, etc.)

Function mode

Allows the user to set the following functions or check the setting contents.

- Calibration number selection

- Decimal point display position

- Current calibration data, etc.

C function mode

Allows the user to set the following functions or check the setting contents.

- Detection zone

- Detection operation, etc.

P function mode

This mode is divided into the following four modes.

- CCAL mode: Calibration

- CADJ mode: Fine adjustment of calibration results

- VCAL/VADJ mode: Calibration or adjustment for options such as current/voltage output card

CAL selection mode

Used to check the following items.

- ROM version of CSD-709

- Mounted options

- Externally controlled operation, etc.

CHECK mode

(Measurement mode)

Switching to Check Mode

(1) Press the [***] key in the normal measurement mode to display [xxx] .

(5) Press the [***] key.

The current detection zone number will be displayed.

Stored detection

zone number

PEAK/TRACK input

0

Detailed

Calibration

Procedure

Detailed

Calibration

Procedure

(3) Pressing the [***] key displays a two-digit number following [xxx] .

(4) Change the display to [xxx] .

: Select a digit to change.

: Change the value of the selected digit.

(5) After displaying, press the [***] key.

The current calibration number (0 to 3) appears.

Set calibration number

(6) Press the [***] key to select a calibration number with which you want to

save the calibration result. A calibration number changes

in the following order: [0] -> [1] -> [2] -> [3].

(8) Press the [***] key twice to return to the measurement mode.

The display shows [xxx] and then it returns to the measurement mode.

Calibration

Procedure

Detection Procedure Detection Procedure Detection Procedure Detection Procedure

Detection Procedure

Check Mode Check Mode Check Mode Check Mode

Check Mode

(4) Change the display to [xxx] .

: Select a digit to change.

: Change the value of the selected digit.

(5) After displaying, press the [***] key.

The current detection operation number will be displayed.

Stored detection

operation number

Modes

Loading...

Loading...