INSTALLMENT&OPERATION

ForMMA

Correctlyconnecttheelectrodeholderandearthclampaccordingtothesketch.

1. Put the cable connector of the electrode holder to the negative terminal “-“and

fastenitclockwise.

2. Pleasefollowpoint1toconnecttheearthclamptothepositiveterminal“+”

3. Please pay attention to the connecting polarity and there are two connecting

methodforDCweldingmachine:positiveconnectionandnegativeconnection.

3.1 Positive connection: holder connects with “-“polarity, work-piece with the “+”

polarity.

3.2 Negative connection:work-piecetothe“-“polarity,electrodeholdertothe“+”

polarity.

3.3 Choose suitable method according to the welding requirement. If unsuitable

methodisselected,itwillcauseunstablearc,morespattersandconglutination.

Ifsuchcaseoccurs,pleasechangethepolarityoftheweldingcables.

4. Switchto“MMA”.

5. Switch the power switch to “ON” position then the cooling fan will start to work

immediately.

6. Pleaseadjustappropriateweldingcurrentandrodaccordingtothicknessofwork-

pieceandweldingcraft.

Electrodestandard

ElectrodeDiameter(mm)

INSTALLMENT&OPERATION

ForTIG

1.Connectgashosewithcopperconnectiononrearpanelofthemachinethenfasten

theconnectorwithhoseclamptopreventfromleakinggas.

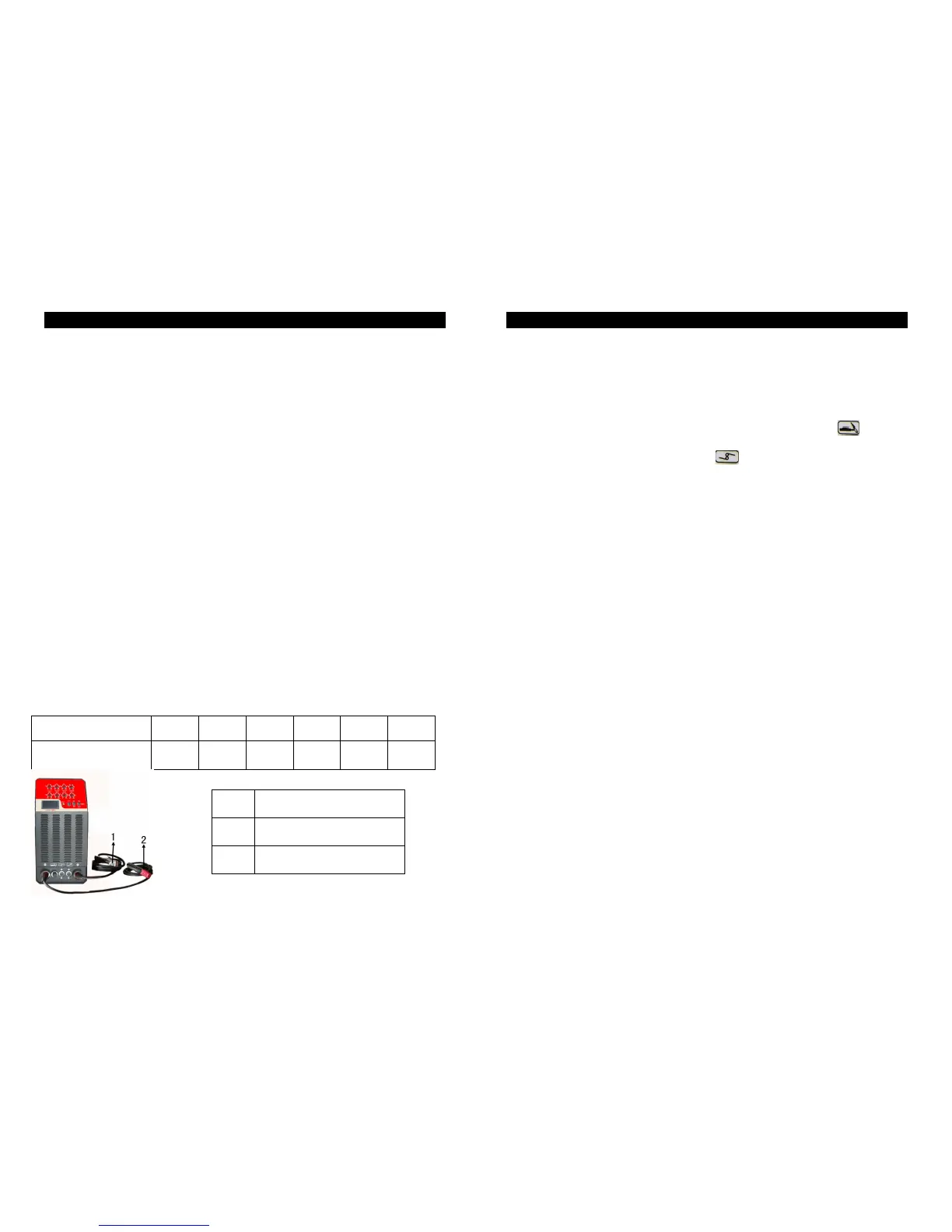

2.Pleaseconnecttheearthclampandtorchcorrectlyasbelow:

2.1 The connectorofgas-electricityintegration to the front panel

and fasten it

clockwise.

2.2 Thepinconnectortothefrontpanel

andfastenitclockwise.

2.3 Thecableconnectoroftheearthclamptothepositiveterminal“+”.

3.Switchto“TIG”andclickthepowerswitchto“ON”thenthecoolingfanwillstartto

workimmediately.

4.Opentheargonregulatorvalveandadjusttoadequateairpressureandflow.

5.Clickonthetorchswitchandthenthesolenoidvalveclickson,alsoHFarc-striking

canbeheard,meanwhileargongasflowsoutthroughtip.

Attention:Thetorchswitchshouldbekeptonforseveralsecondsbeforeweldingforthe

firsttime,andit’sreadytoworkafteralltheairisout.Andargonwillstillflow

outinseveralsecondswhentheweldingstopsandthisspecialdesignisto

continue protecting the welding spot before cooling. In that case, please

remaintheweldingpositionforawhileeventhearcisextinct.

6.Pleaseadjustappropriateweldingcurrentaccordingtothethicknessofworkpiece

andweldingcraft.

7. Pleasekeepadistanceof2-4mmbetweenthetungstenandwork-piece,thenclick

onthetorchswitchandtherewillbeHFsparkbetweenelectrodeandwork-piece,

afterarc-strikingthesoundfromtheHFdischarginginthemachinewilldisappearat

once,andnowit’sreadytoweld.

Loading...

Loading...