Chapter 8 Clutch and driveline

a-9

\ -w

Mating marks

13.3 With the cente; bearing and &&haft mounted S?cUrely in

a vise, remove the center yoke nut

.,A j

\

13.4 Work the center bearing bracket assembly back-and-forth

while pulling it off the shaft

13.5 Pull the bearing off the shaft with a puller

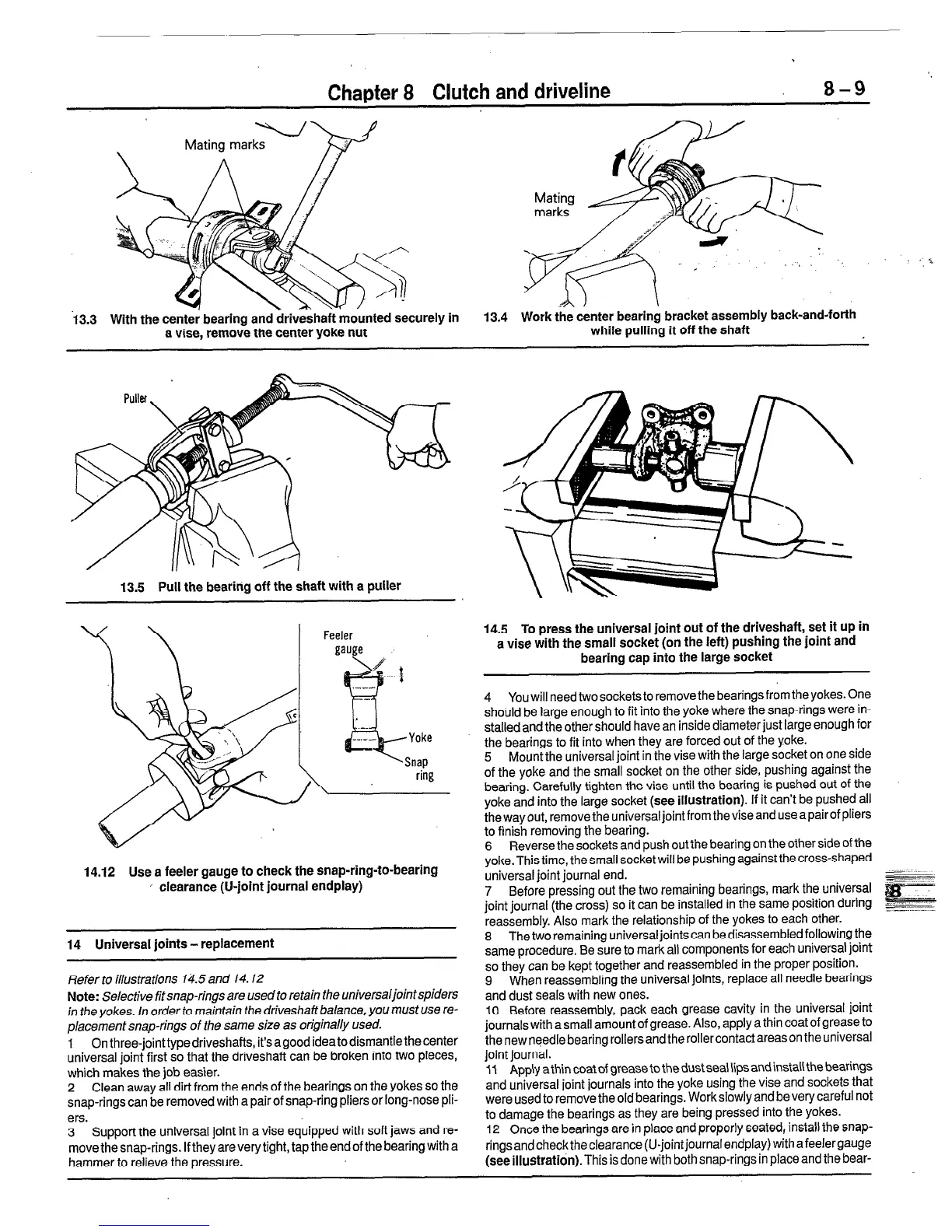

14.12 Use a feeler gauge to check the snap-ring-to-bearing

’ clearance (U-joint journal endplay)

14 Universal joints - replacement

Refer to illustrations 14.5 and 14.12

Note:

Selective fit snap-rings are used to retain the universaljointspiders

in the yokes. In order to maintain the driveshaft balance, you must use re-

placement snap-rings of the same size as originally used.

1 Onthree-jointtypedriveshafts, it’sagoodideatodismantlethecenter

universal joint first so that the driveshaft can be broken into two pieces,

which makes the job easier.

2 Clean away all dirt from the ends of the bearings on the yokes so the

snap-rings can be removed with a pair of snap-ring pliers or long-nose pli-

ers.

3 Support the universal joint in a vise equipped with soft jaws and re-

move the snap-rings. If they are very tight, tap the end of the bearing with a

hammer to relieve the pressure.

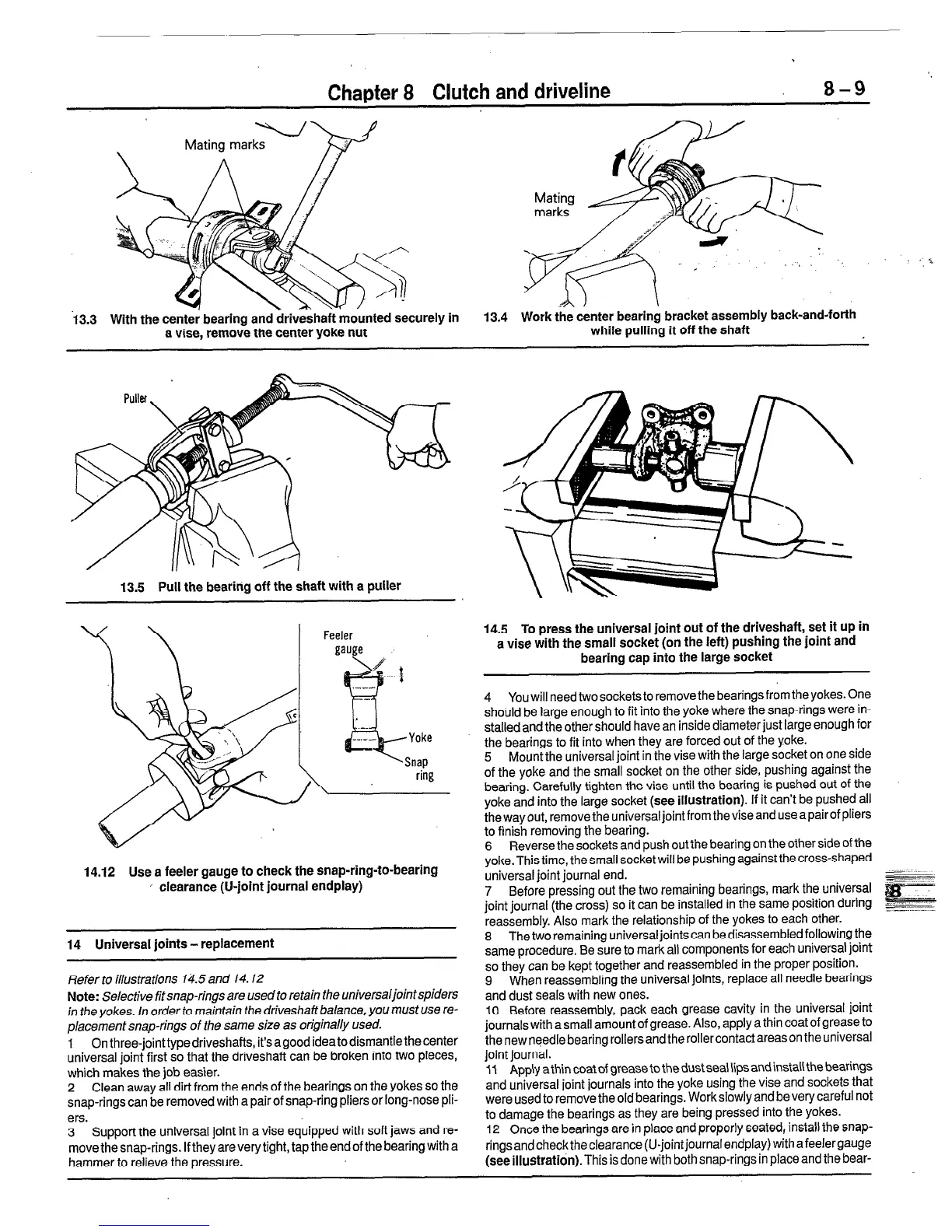

14.5 To press the universal joint out of the driveshaft, set it up in

a vise with the small socket (on the left) pushing the joint and

bearing cap into the large socket

4 You will need two sockets to remove the bearings from the yokes. One

shoirld be large enough to fit into the yoke where the snap-rings were in-

stalled and the other should have an inside diameter just large enough for

the bearings to fit into when they are forced out of the yoke.

5 Mount the universal joint in the vise with the large socket on one side

of the yoke and the small socket on the other side, pushing against the

bearing. Carefully tighten the vise until the bearing is pushed out of the

yoke and into the large socket (see

illustration).

If it can’t be pushed all

the way out, remove the universal joint from the vise and use apairof pliers

to finish removing the bearing.

6 Reverse the sockets and push out the bearing on the other side of the

yoke. This time, the small socket will be pushing against the cross-shaped

universal joint journal end.

7 Before pressing out the two remaining bearings, mark the universal

joint journal (the cross) so it can be installed in the same position during

reassembly. Also mark the relationship of the yokes to each other.

8 The two remaining universal joints can be disassembled following the

same procedure. Be sure to mark all components for each universal joint

so they can be kept together and reassembled in the proper position.

9 When reassembling the universal joints, replace all needle bearings

and dust seals with new ones.

10 Before reassembly, pack each grease cavity in the universal joint

journals with a small amount of grease. Also, apply a thin coat of grease to

thenewneedle bearing rollersand therollercontactareason theuniversal

joint journal.

11 Apply athin coat of grease to the dust sea\ lips and install the bearings

and universal joint journals into the yoke using the vise and sockets that

were used to remove the old bearings. Work slowly and be very careful not

to damage the bearings as they are being pressed into the yokes.

12 Once the bearings are in place and properly seated, install the snap-

ringsandchecktheclearance (U-jointjournalendplay) withafeelergauge

(see illustratidn).

This is done with both snap-rings in place and the bear-

Loading...

Loading...