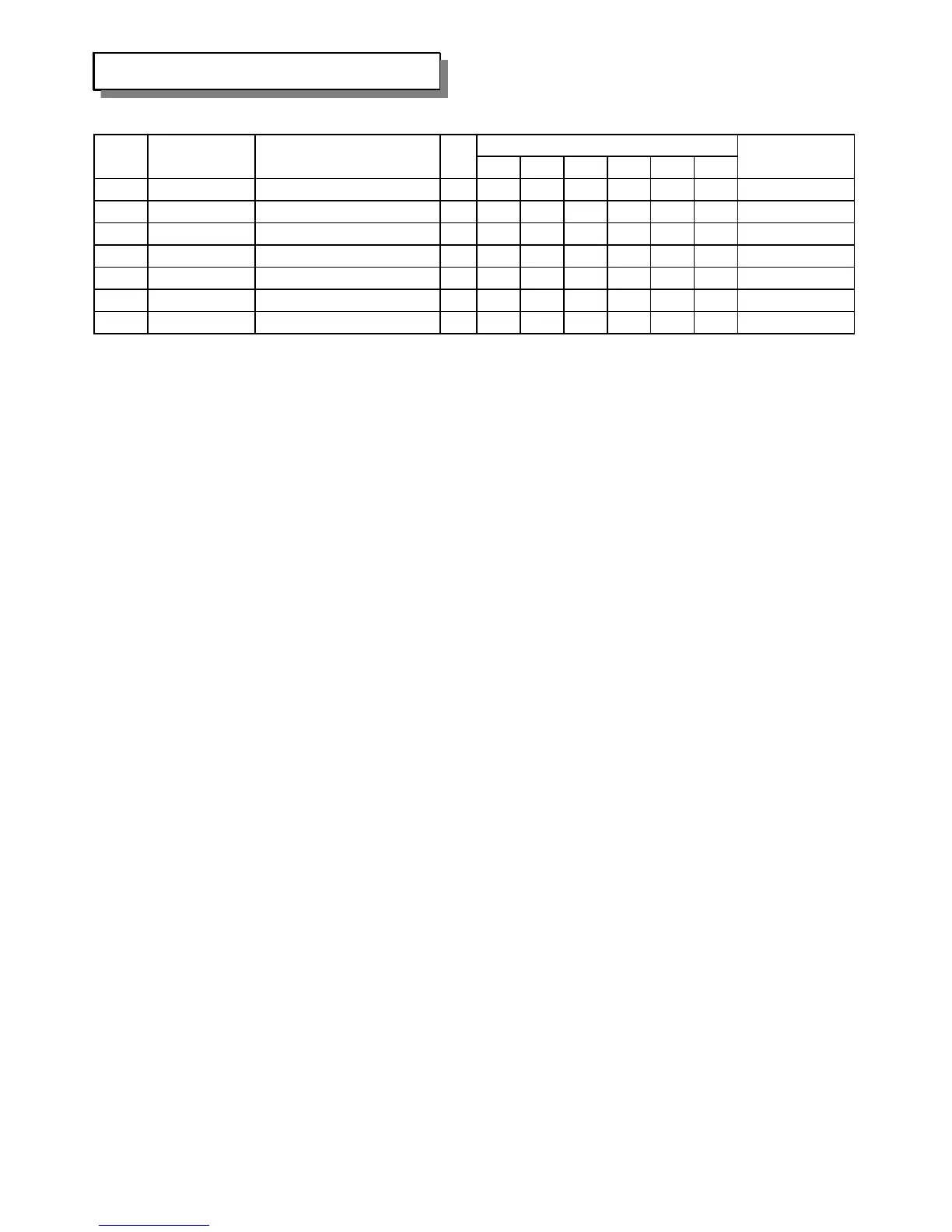

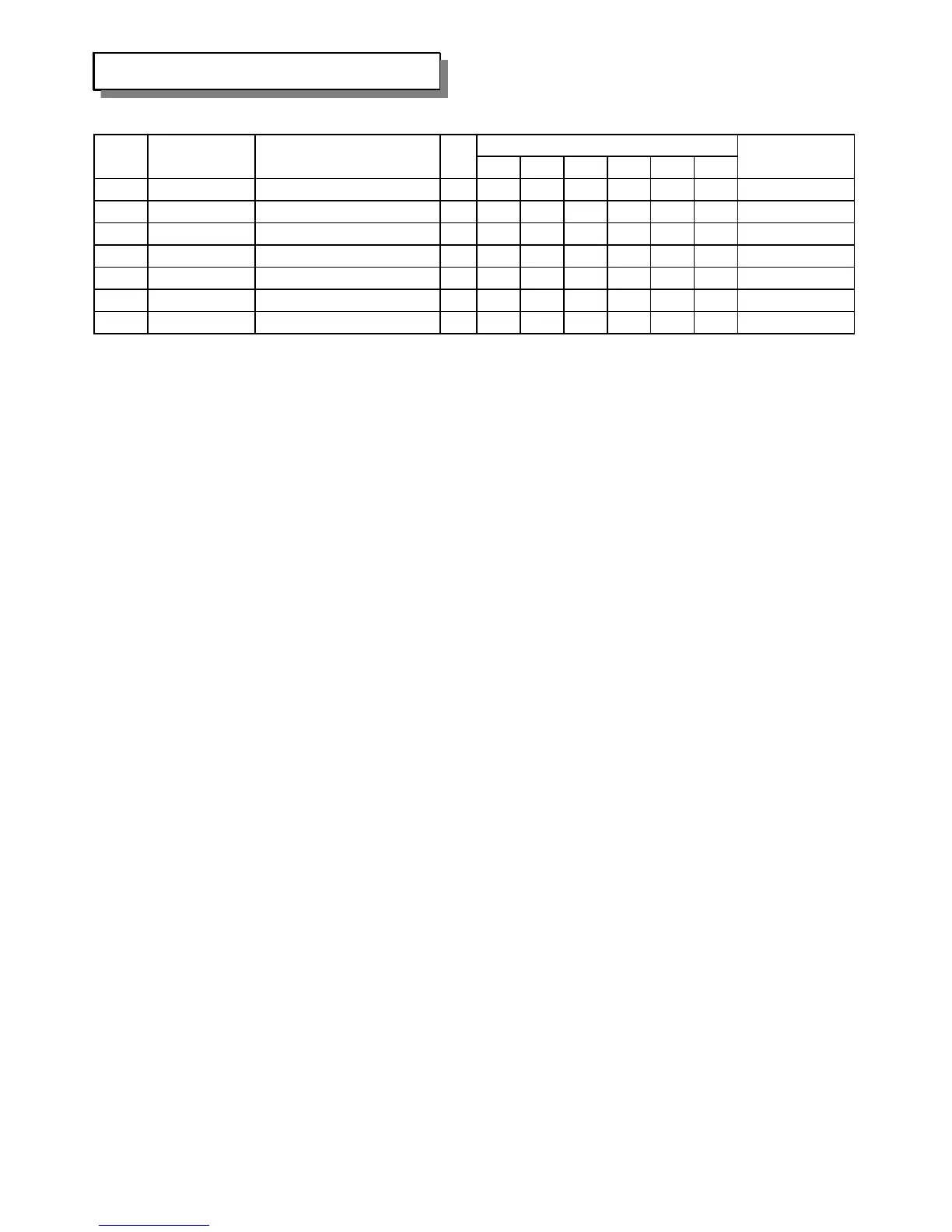

SRK63ZEA-S1

Recommendable Purchased Q'ty

10 30 50 100 500 1000

38 RKW129A202 BRACKET MOTOR ( L ) 1 1112

39 RKS504A601C HARNESS ASSY 1

1

1

1

3

1112FOR FAN MOTOR

40 RKW032A200 PLATE,INSTALLATION 1112

41 RKW129A212 COVER(PIPE) 1 1112

42 RKW132A200 LID(R) 1124

43 RKW132A201 LID(L) 1124

44 SSA913A007A SCREW,TAP

NoteNo. Part No. Part Name RE.Q

‑ 85 ‑

Loading...

Loading...