Modco Industries LLC, 10650 FM 1484 Conroe, TX 77301 / Phone: 936-539-9222 / FAX: 936-622-6818

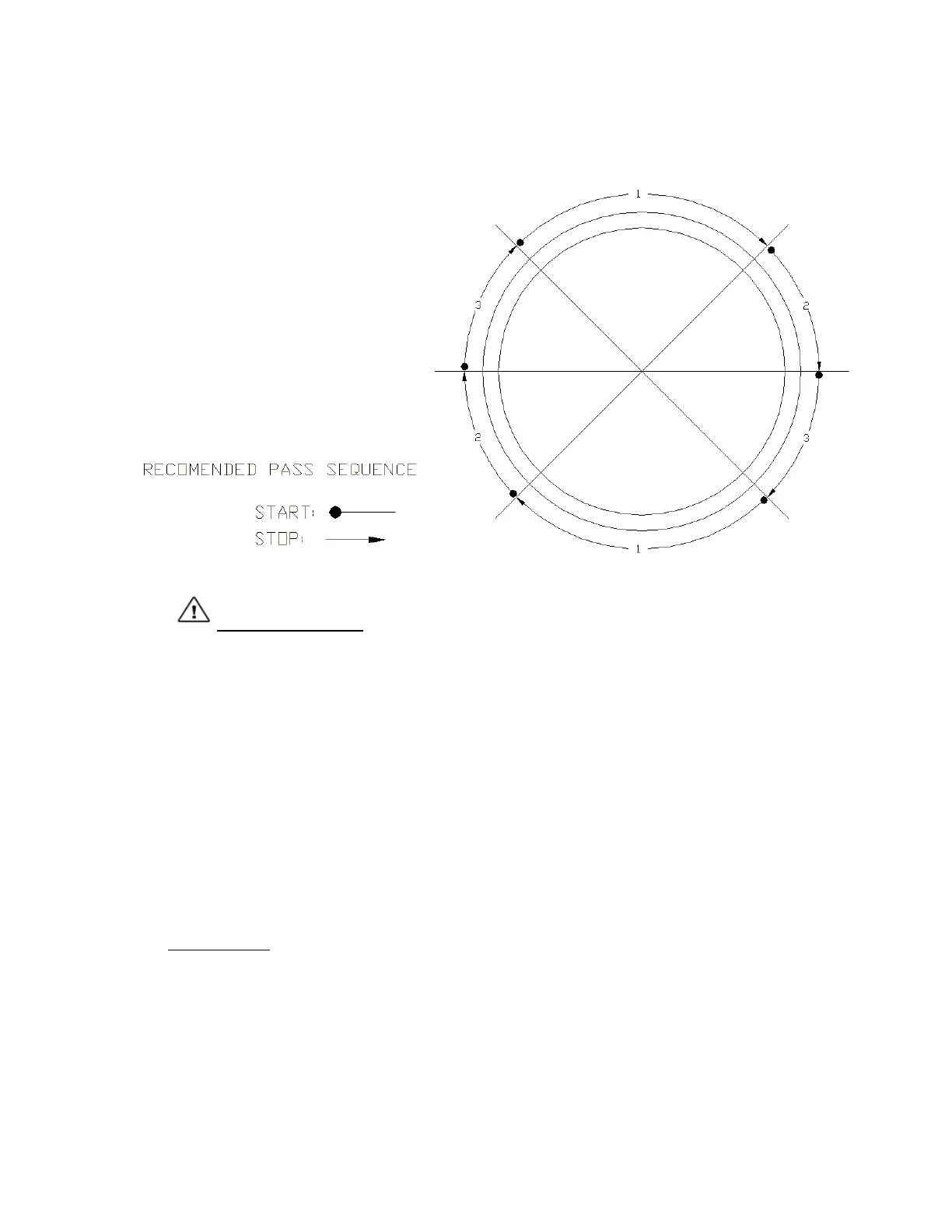

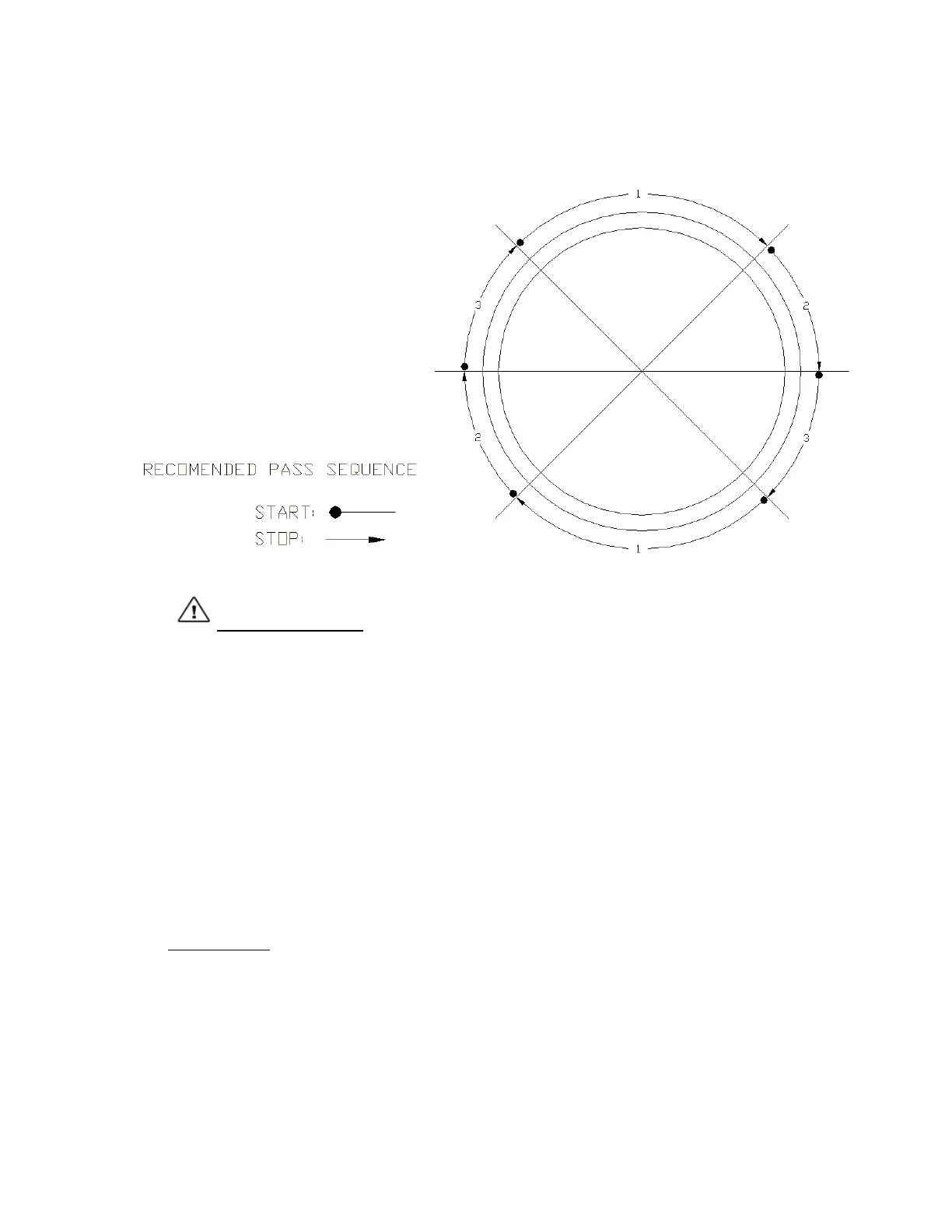

WELD STRINGER BEADS AND HOT PASS WITH TWO MEN ON OPPOSITE SIDES TO EQUALIZE

WELDING STRESSES. FOLLOW THE SEQUENCE SHOWN IN DIAGRAM. MAKE CERTAIN THAT

THE WELDING FROM 7:30 BACK TO 4:30 PROCEEDS WITHOUT INTERRUPTION OR ANY TIE-

IN AT 6:00

VERY IMPORTANT: CAREFUL ATTENTION TO WELDING HEAT AND PROCEDURE

IS RECOMMENDED TO AVOID DISTORTION OF SUB FACE

AND THREADS.

8. TO INSURE THAT NO WARPAGE HAS OCCURRED DURING WELDING, THE FOLLOWING

PROCEDURE MAY BE USED TO BLUE CHECK THE SEALING SURFACES:

1. APPLY EVEN LAYER OF NON-DRYING PRUSSIAN BLUE TO THE CAP SEALING SURFACE.

2. SCREW CAP ONTO SUB TIGHT BY USING ACTUATOR DEVICE.

3. REMOVE CAP AND CHECK FOR CONTINUOUS TRACE OF BLUEING ON O-RING LANDS

OF SUB FACE.

9. LUBRICATE O-RING AND REPLACE IN GROOVE IN SUB FACE.

10. IMPORTANT: FOR VESSELS OR BARRELS THAT REQUIRE POST HEAT TREATMENT AND

STRESS RELEIVING, IT IS IMPORTANT THAT THE BEARINGS IN THE JIB

COLUMN HOUSING AND HINGE ARE BE REMOVED AS WELL AS THE

TROLLEY ASSEMBLY AND PRESSURE WARNING DEVICE.

11. REFER TO THE MODCO FIGURE 500 CLOSURES OPERATION AND MAINTENANCE

INSTRUCTIONS FOR HINGE ADJUSTMENTS AND LUBRICATION PROCEDURES AFTER

FABRICATION OF CLOSURE IS COMPLETED.

Loading...

Loading...