70 20’ Predator

HYDRAULIC HOSES

5HSODFHSLQFKHGDQGEURNHQ+\GUDXOLF+RVHVDWRQFH7LJKWHQDQ\K\GUDXOLFÀWWLQJZLWKÁXLGOHDNLQJ

IURP LW ,I ÁXLG VWLOO OHDNV ORRVHQ WKH ÀWWLQJ DSSO\ D SLSH WKUHDGFRPSRXQG WR WKH WKUHDGV DQG

WLJKWHQ&DUHPXVWEHH[HUFLVHGZKHQWLJKWHQLQJK\GUDXOLFÀWWLQJV7RRPXFKWLJKWHQLQJFDQFDXVH

WKHÀWWLQJVWRFUDFNDQGUHTXLUHGUHSODFHPHQWÀWWLQJV

$OWKRXJKDVPDOODPRXQWRIRLOZLOOEHSUHVHQWIURPEOHHGLQJDW DOOK\GUDXOLFÀWWLQJVVLJQLÀFDQW

OHDNLQJDURXQGWKH%UHDWKHU3OXJRQWKHF\OLQGHULVGDPDJHGRUWRRPXFKK\GUDXOLFÁXLGLVORVW

SKID SHOES

6NLGVKRHVDUHPDGHRGFDUERQVWHHOWRUHGXFHZHDUDQGLQFUHDVHVHUYLFHOLIH3UHPDWXUHZHDUFDQ

EHFDXVHGE\WKHFXWWHUZLQJVHFWLRQVEHLQJVHWWRRORZZKLFKDOORZVWKHZLQJVNLGVKRHVWRGUDJ

RQWKHJURXQG'UDJJLQJWKHVNLGVKRHVRQWKHJURXQGRUUXQQLQJWKHVNLGVKRHVLQWRVROLGREMHFWV

FDQFRQWULEXWHWRHDUO\IUDPHIDLOXUHRQWKHFXWWHU5HSODFHZRUQVNLGVKRHVDVUHTXLUHG

WHEELS BEARINGS

Every six months, the wheel hubs should be removed. Remove, clean, and inspect the bearings

PDNLQJFHUWDLQWKDWWKH\DUHIUHHRIDOOVLJQVRISLWWLQJUXVWGHFD\RUGHIRUPDWLRQ,IDQ\RIWKHVH

problems exist, the cups and cones in the wheel hub should be replaced. Replace the cups and

cones as a set. This prevents a continuation of the original problem. If the bearings are in good

VKDSHSDFNWKHQZLWKJUHDVH

3XWWKHEHDULQJVHDOEDFNLQWRWKHZKHHOKXE

and replace the hub. Tighten the adjusting nut

until there is noticeable drag while turning the

ZKHHO%DFNRIMXVWHQRXJKWRSURYLGHDIUHHUROOLQJ

ÀW,QVHUWDQGVSUHDGWKH&RWWHU3LQ,QVWDOOWKHKXE

cap. Fill the hub completely with #2 bearing grease.

HARDWARE

&KHFNQXWVEROWVDQGRWKHUPLVFHOODQHRXV

hardware regularly. Loose hardware is easily

lost, cause increased wear on parts, and increase

WKHFKDQFHRIEUHDNGRZQ/RRVHKDUGZDUHFUHDWHV

potential hazards which could result in personal

injury to the operator, support personnel and

E\VWDQGHUV8VHWKH´7RUTXH&KDUWµEHORZZKHQ

tightening bolted connections.

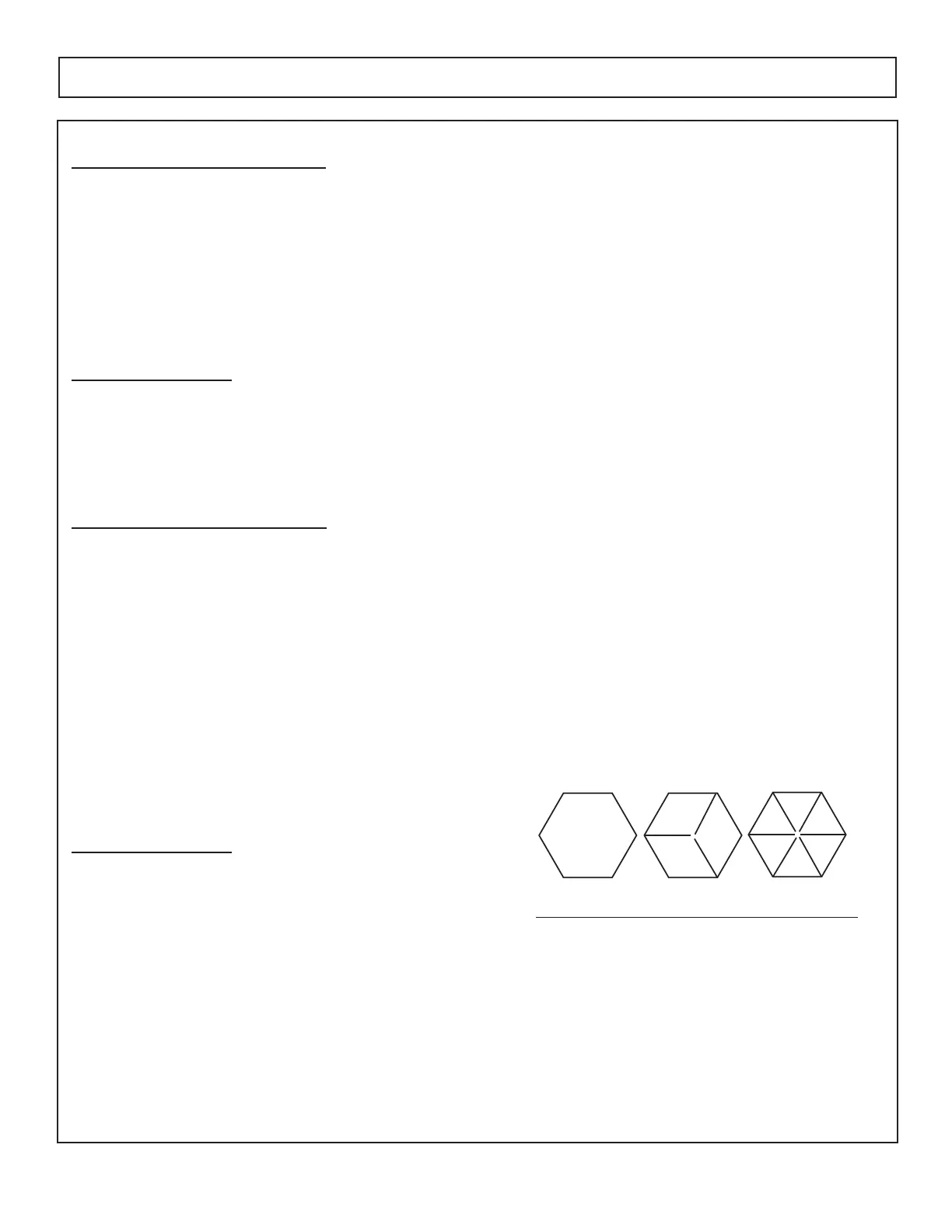

BOLT PLAIN THREE SIX

DIAMETER HEAD DASHES DASHES

1/4 .....not used .......10 (14) ..........14 (19)

5/16 . . . not used ........20(27) .......... 30(41)

3/8 ....not used ........35(47) .......... 50(68)

7/16 ......35(47) ........55(75) .........80(108)

1/2 ........55(75) ...... 85(115) ........120(163)

9/16 .... 75(102) ..... 130(176) ........175(237)

5/8 ..... 105(142) ..... 170(230) ........240(325)

3/4 .....185(2510 ..... 300(407) ........425(576)

7/8 ..... 160(217) ..... 445(603) ........685(929)

1 ...... 250(339) ..... 670(906) ......1030(1396)

1 1/8 . . . 330(447) ....910(1234) ......1460(1979)

1 1/4 . . . 480(651) . . . 1250(1695) ......2060(2793)

2 (B)

5 (D) 8 (F)

RECOMMENDED TORQUE

IN FT-LBS (NM)

COARSE AND FINE THREADS

MAINTENANCE

Loading...

Loading...