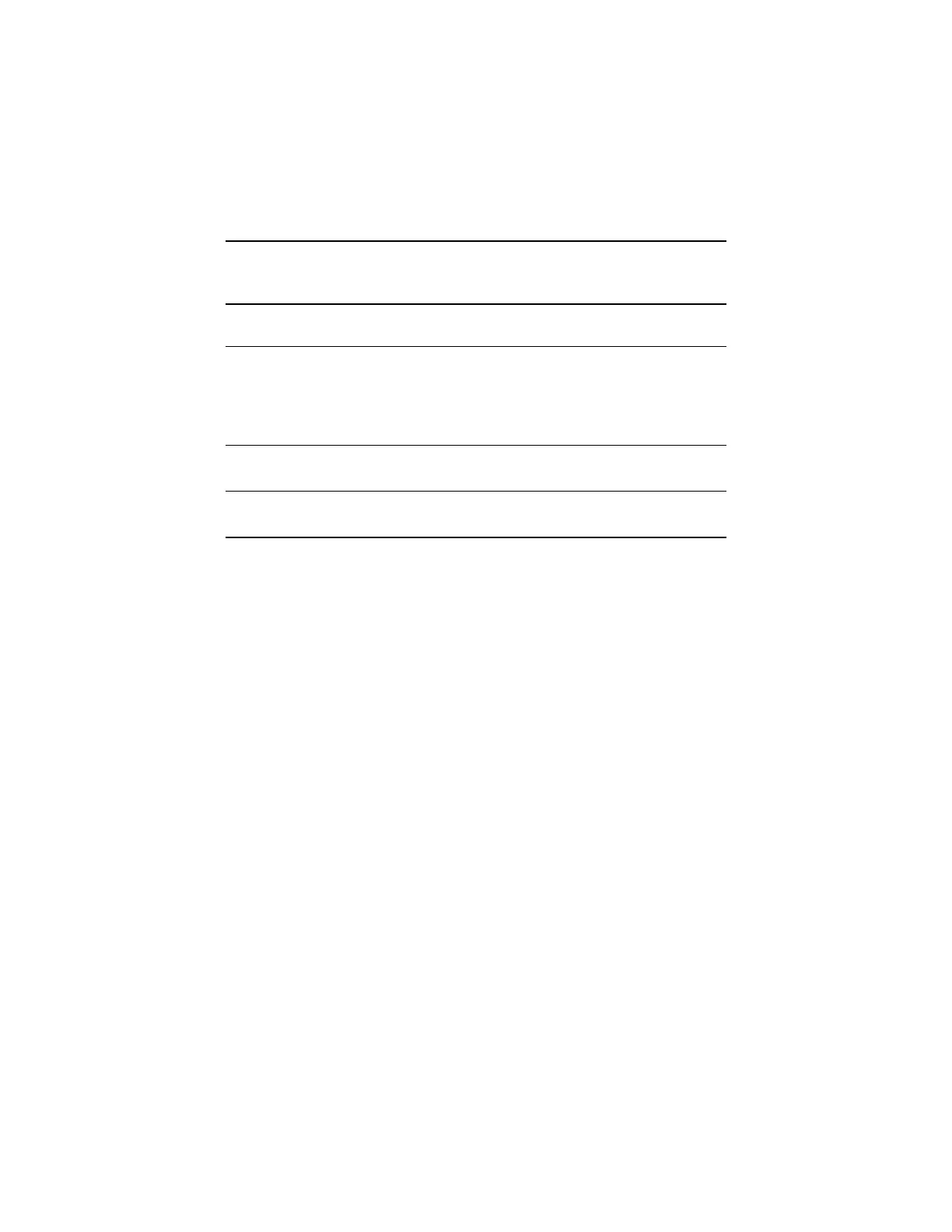

Table 2-2. Expected Alarm Relay States Gas Type

SETPOINT ALARM ALARM RELAY ALARM RELAY

SETTING STATE WITH STATE WITH

ZERO GAS SPAN GAS

APPLIED APPLIED

Lower than Above Set-point Not active Activated

span gas

concentration

Lower than Below Set-point Activated Not Active (NOTE:

span gas If alarm relays are

concentration configured as latching,

the alarm must

be cleared after the zero

gas is removed for this

state to be correct)

Higher than Above Set-point Not Active Not Active

span gas

concentration

Higher than Below Set-point Activated Activated

span gas

concentration

NOTE: Personnel performing the Ultima X proof test should be trained

in SIS operations, including bypass procedures, Ultima X

Monitor maintenance and company management of change

procedures.

Routine Maintenance

Besides proof testing, the following three maintenance procedures that

must be performed on the Ultima X gas monitors.

Periodic Calibration

To ensure accuracy and detect any sensor problems, calibrate the:

• XE and XA monitors a minimum of every three months

• XIR monitor according to the requirements as documented in the

Ultima X Series Gas Monitor instruction manual (P/N 10036101).

Calibrate monitors with catalytic combustible sensors when they have

been exposed to non-combustible chemicals known to reduce sensor

sensitivity (Silanes, Silicates, Silicones and Halides). Use the regular

calibration method given in the Ultima X Series Gas Monitor instruction

manual (P/N 10036101).

2-5

Loading...

Loading...