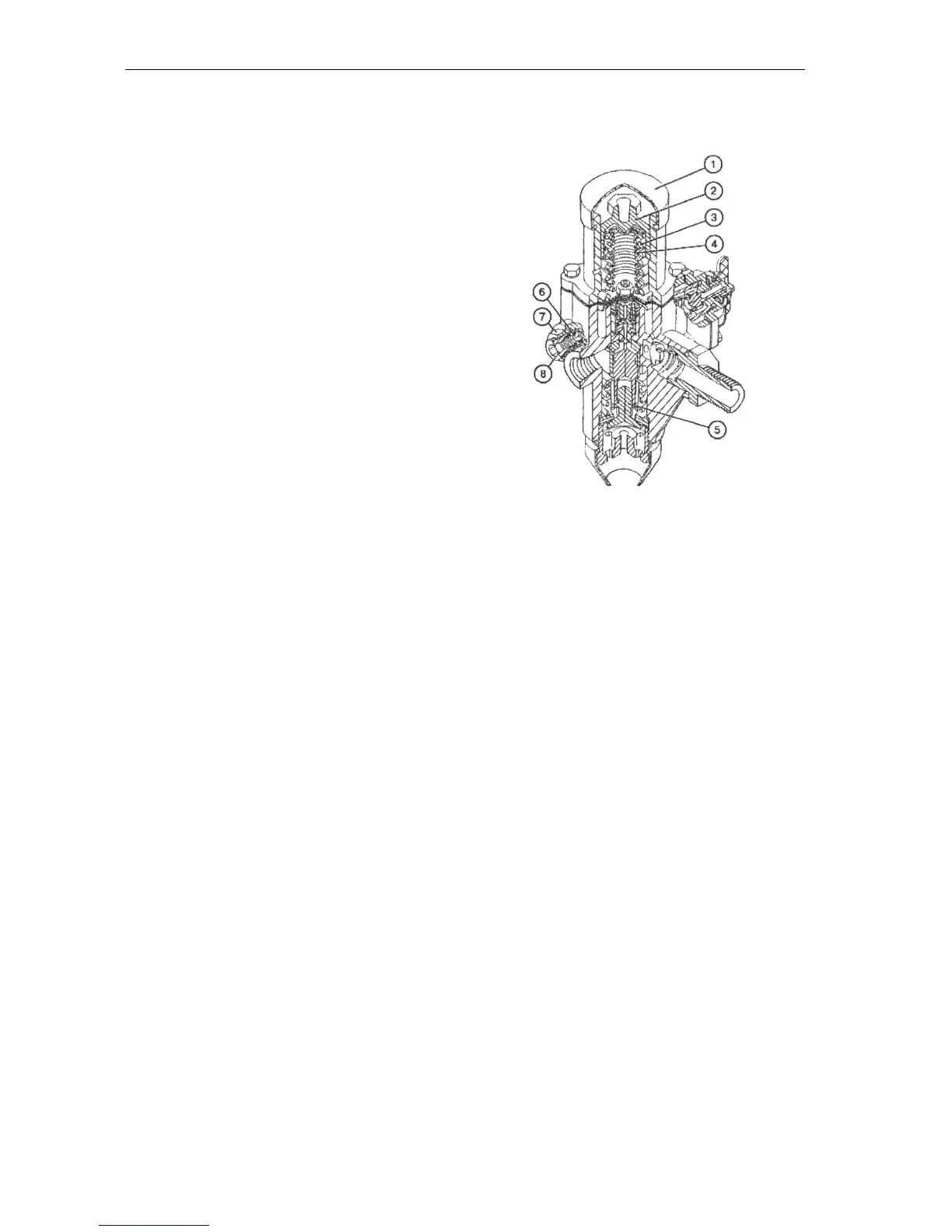

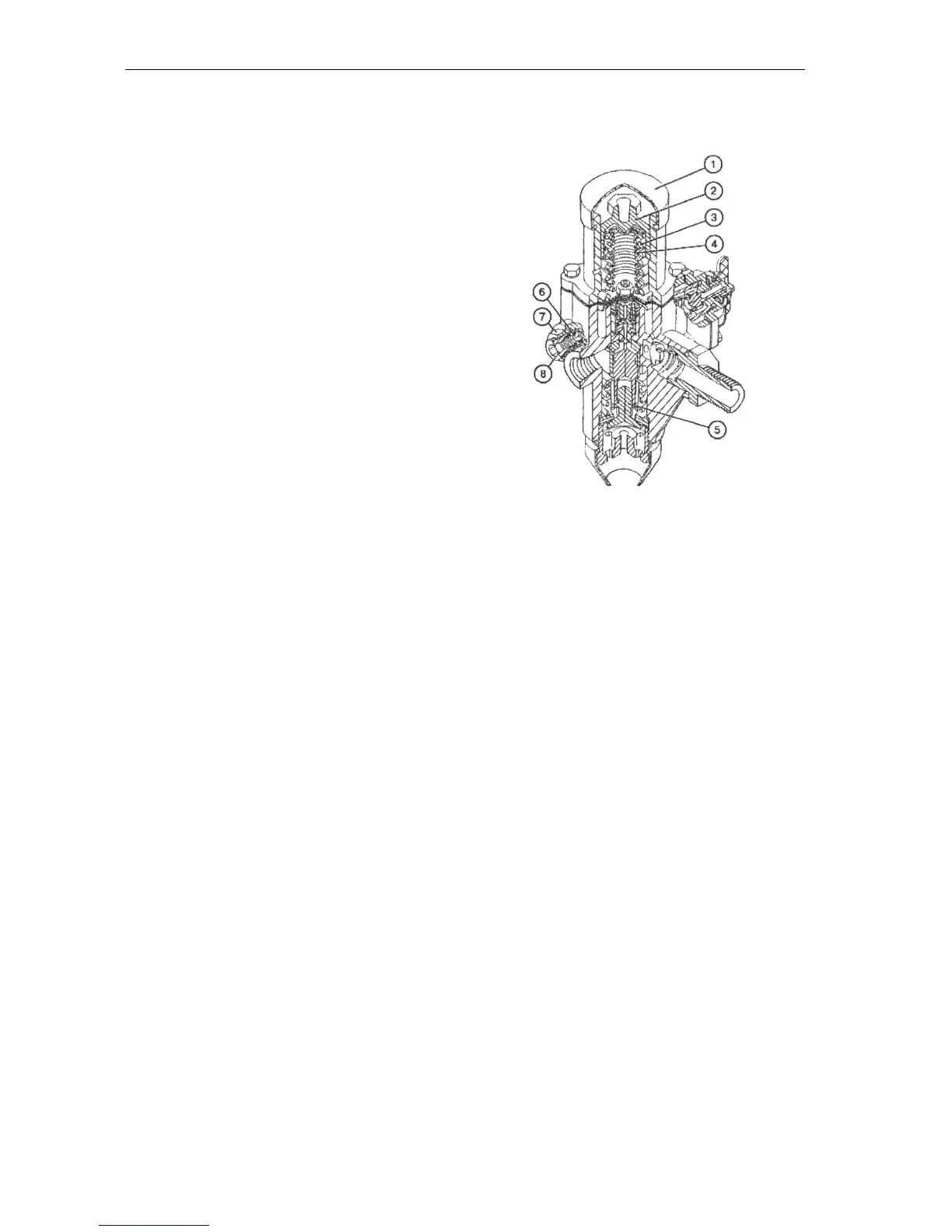

Checking and adjusting the pneumat-

ic system pressure regulator

After 1000 hours of operation of the

tractor (M-3), in case of malfunction of

the pressure regulator, as well as after

its disassembly for washing or replace-

ment of worn-out parts, perform the ad-

justing operation as follows:

• Attach a pressure gauge with the

resolution of 0.1-0.2 kgf/cm

2

and

scale of at least 16 kgf/cm

2

to the bot-

tle for the period of verification and

adjustment.

• Remove the cap (1).

• Using a spanner, screw the cover (2)

into the casing to the stop.

• Start the engine. Turn on the com-

pressor and fill the bottle with com-

pressed air so that the safety valve

(6) would operate at 8.5-10 kgf/cm

2

. If

the valve operates at a pressure ex-

ceeding the said limits, adjust it by

means of the screw (8), having pre-

liminary loosened and then tightened

the lock nut (7).

• Adjust the force of the springs (3, 4)

by unscrewing gradually the cover (2)

in such a way that the air pressure in

the bottle at which the overload valve

(5) opens would be 7.7-8.0 kgf/cm

2

• Fix this position of the cover (2) by

applying paint to the treaded part of

the casing and put on the cap (1).

• Open slightly the condensate remov-

al valve in the bottle and reduce the

air pressure to 6.5-7.0 kgf/cm

2

. At

these values, the valve (5) shall be-

come closed and switch the com-

pressor to filling the bottle with com-

pressed air.

• Disconnect the reference pressure

gauge from the bottle.

Loading...

Loading...