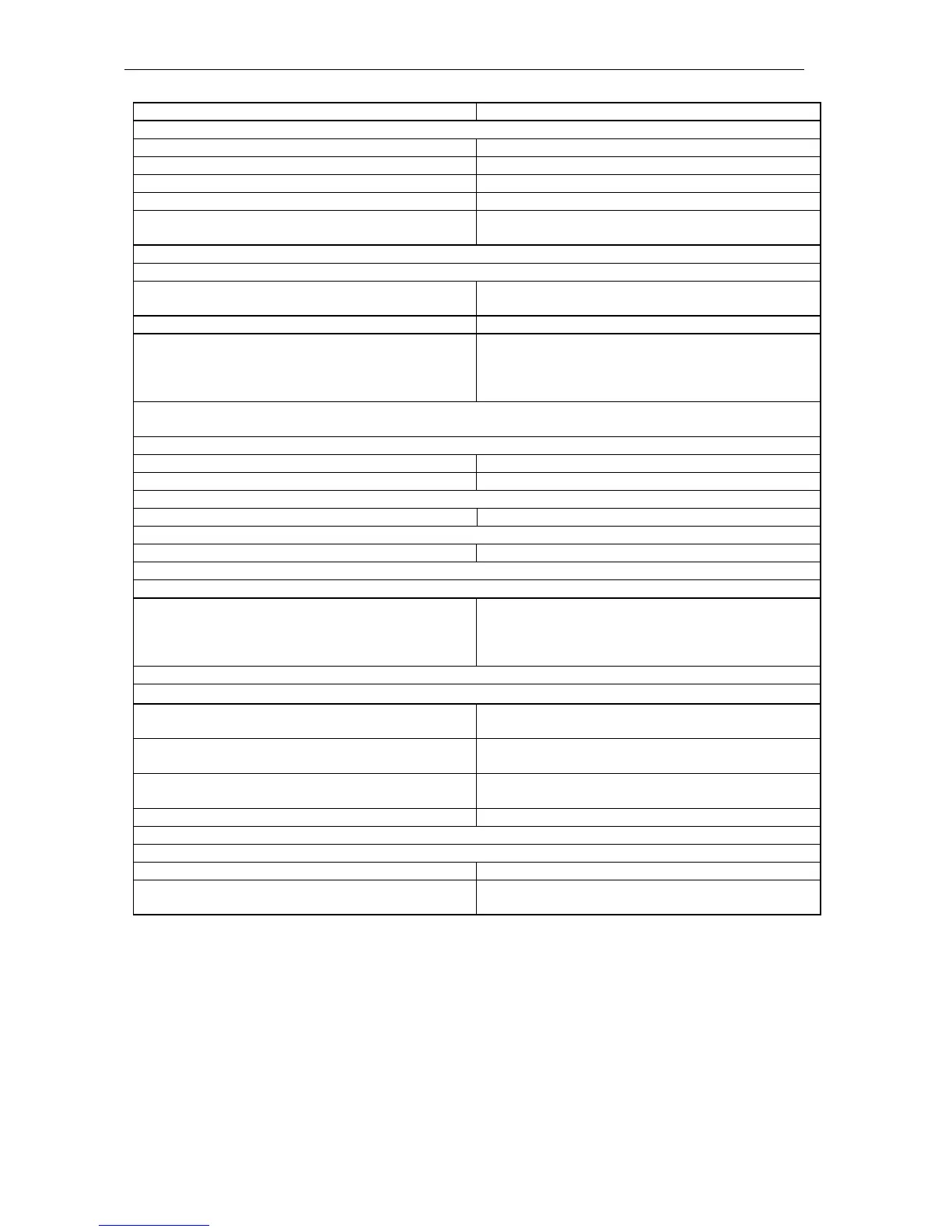

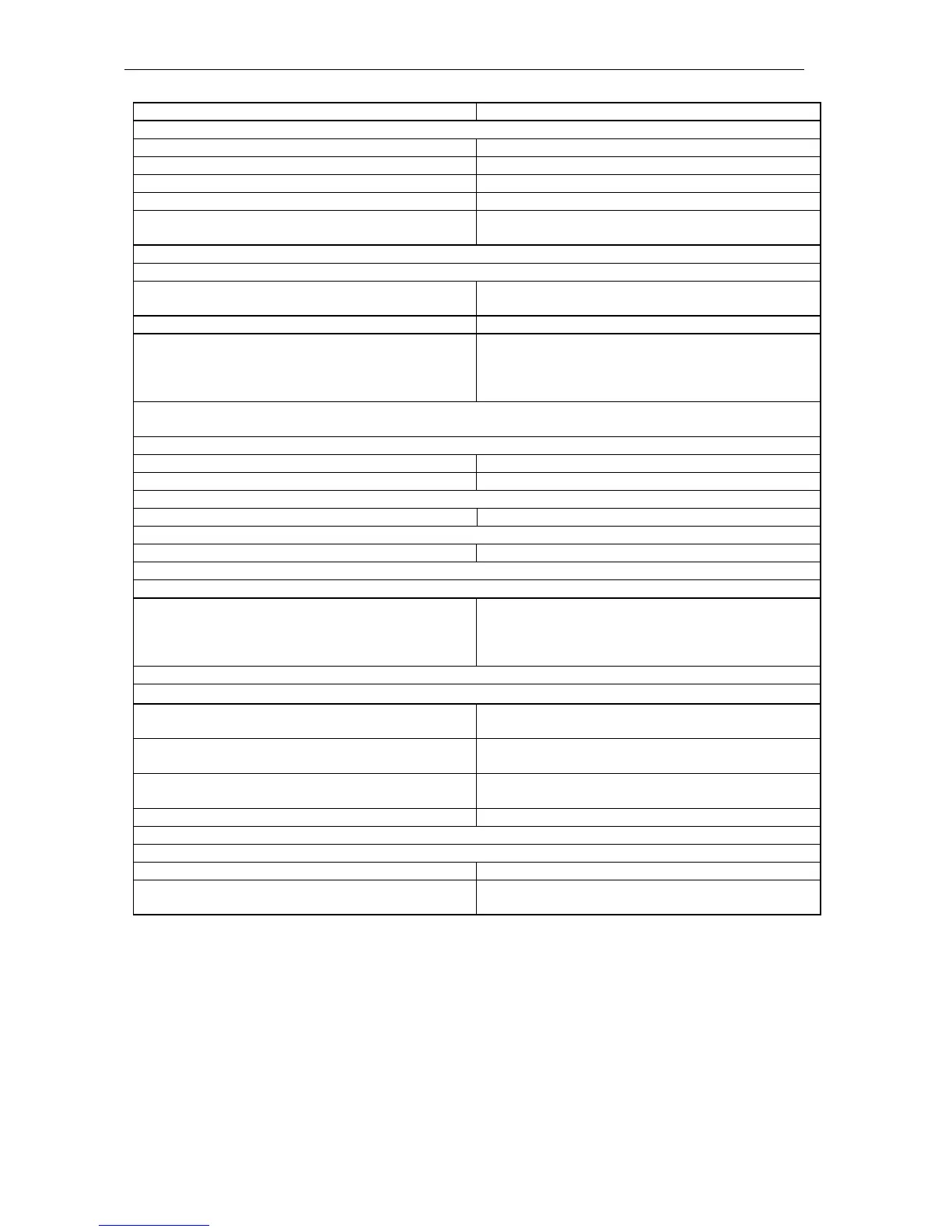

TROUBLE, EXTERNAL MANIFESTATION

Oil pressure in heated engine is below the allowable level

Pressure sensor or indicator is faulty.

Replace them by new ones.

Engine lubrication system pump is faulty.

Eliminate the failure or replace the pump.

Oil level in the crankcase is below the allowable level.

Add oil to the upper mark of the oil-measuring rod

Sticking of the drain valve of centrifugal oil filter.

Wash up the valve and adjust the pressure.

Maximum wear of coupling “crankshaft journal – b e a r -

ings”

Send the engine for repair

Turbocharger rotor does not rotate (absence of typical high tone sound)

Ingress of foreign objects hampering the rotor rotation

Remove the inlet and exhaust branch pipes. Remove the

foreign objects.

J a mming of the rotor in the bearing.

Replace the turbocharger.

Higher oil emission from the compressor or turbine

side, loss of air-tightness of turbocharger seals.

Remove the turbocharger from the engine and send it

for repair.

The clutch does not transfer the full torque

No free travel of the pedal.

Adjust the free pedal travel.

Driven plate linings are worn out.

Replace the linings of the driven plate as an assembly.

The clutch is not disengaged fully

The free pedal travel is increased.

Adjust the free pedal travel.

Ingress of oil into the dry section of the clutch housing

Wear of the cup sealing the crankshaft.

Higher noise in bevel pair

Maladjustment of engagement of the final gear pin -

ion teeth coupling with differential bearings.

Adjust the gap in the engagement of the pinions

(0.20…0.55 mm) and preloading of the differential

bearings (the turning force to be applied to the driv-

en pinion shall be 30…50 N)

AUTOMATIC DIFFERENTIAL LOCK

Automatic differential locking (ADL) fails to operate

No voltage supply to the hydraulic distributor electro-

magnet.

Check electric circuit from the control panel to the

electromagnet in accordance with the diagram.

Sticking of electric hydraulic distributor slide d u e t o

soiling.

Press the electromagnet button to move the slide.

The ADL clutch plates are oiled.

Wash the clutch plates in gasoline, eliminate oil leak-

a ge .

Friction linings of clutch disks are worn out.

Ineffective brake operation (the brakes do not hold)

Maladjustment of the brake control.

Adjust the brake control.

Brake disk linings are oiled or worn out (for “dry”

brakes)

Eliminate the oil leakage. If necessary, replace the

plates.

ATTENTION! A frequent cause of failure of the tractor brakes is the use of trailing and

semi-trailing brakeless machines blocked with the tractor brakes. It is not allowed to use

trailing and semi-trailing brakeless machines blocked with the tractor brakes if their

mass exceeds half mass of the tractor.

Loading...

Loading...