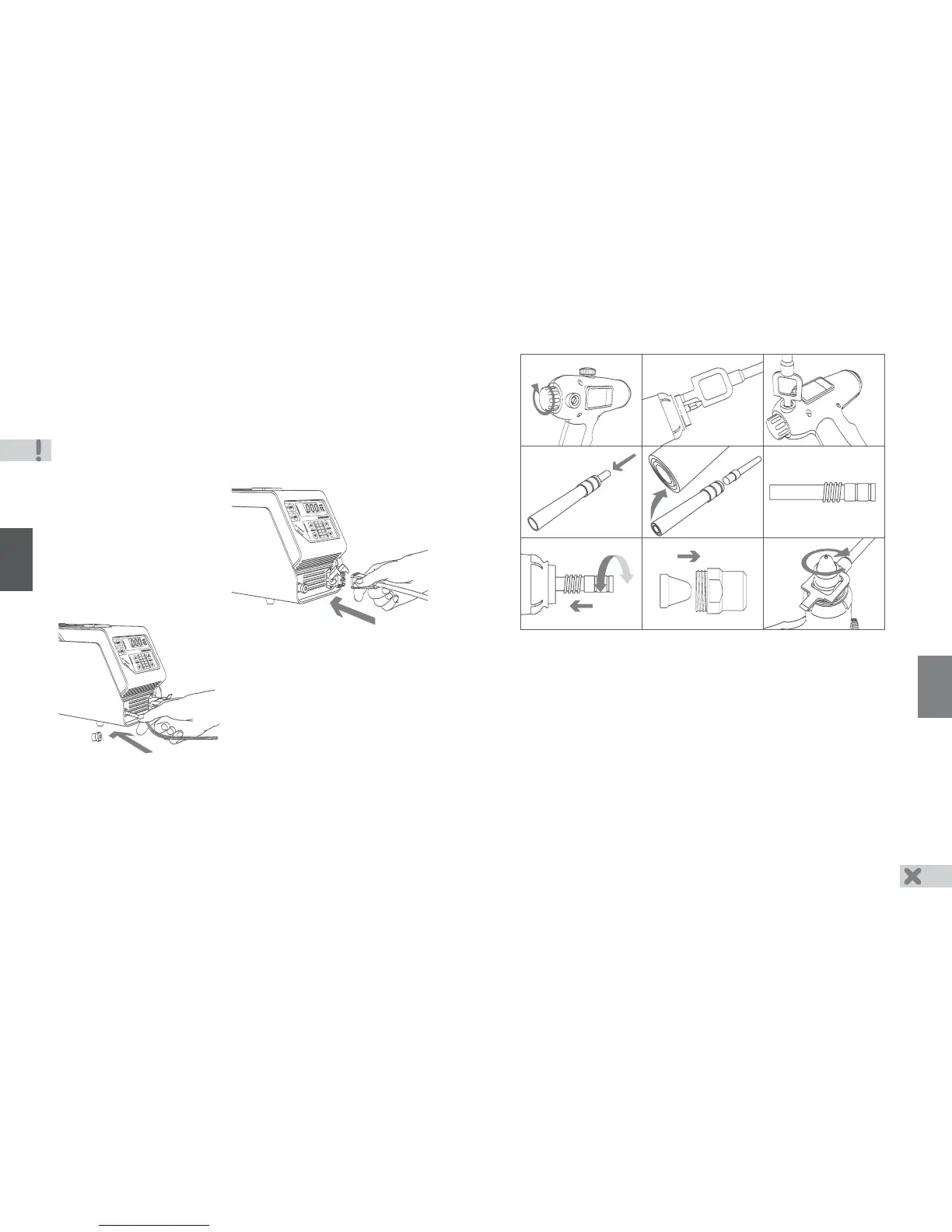

6.6 Torch Assembly

1

2.

(

).

3 Tighten cathode holder retaining screw by turning it clockwise. Do not apply the

significant force when tightening, because the plastic cap of screw may be broken

down. Verify cathode assembly is secure by pulling on it without screw in the outward

direction

4

5.

6

7

8

.

.

. Rotate start button clockwise to hard stop.

. Take cathode assembly and fully insert into torch Rotate cathode assembly around

such that the flat on its tapered end slide into fastener fitting flat is secure if cathode

assembly does not turn Using the combination wrench, insert the cathode assembly

into the torch until the cathode sticks out of the body 19 mm (0.75 inch) for welding

(red mark on wrench) and 17 mm (0.65 inch) for cutting (green mark).

.

. Gently slide quartz tube into thicker end of evaporator.

. Place tapered end of evaporator on a level wooden surface Using thicker end of

plunger, finalize quartz tube installation such that tube end aligns with evaporator

end.

. Install spring into evaporator.

. Rotating evaporator slightly from side to side, slide it over cathode holder keeping it

in alignment.

. Select appropriate nozzle and insert into cap.

9. Place cap and nozzle over protruding section of evaporator making sure there is no

nozzle misalignment Tighten cap clockwise using combination wrench.

It is prohibited:

- to install quartz tube over thinner end of evaporator

6

31

3

4

5 6

7 8

1

2

9

Torch Connection to Power Supply

.

-

-

(see

Figure).

-

.

4.2

- Take cutting torch with

Make certain that power supply ”OFF”

LED is illuminated

Connect torch cable connector to

power supply output connector

Secure connection with connector

latch

green mark

.

4. Cutting - Use distilled water

Study the Safety section and comply with its requirements

Connection of Power Supply

Connect power supply power cable to wall receptacle

- Verify that voltage display and “OFF” LED are illuminated.

Verify that fans are on

.

4.1

-.

-.

Caution

Voltage display may show a value of up to volts if the LED is illuminated

!

5 “OFF” .

18

4

4.3 Power Supply Setup for Torch Start

- Connect MODE II cable with clamp to positive

output on power supply front panel

igure

Press the eft or

(see

F).

-l

5 6 buttons step-by-step

to select position 4 of MODE I current

indicator.

4.4 orch Setup and Servicing

Cutting requires nozzle of diameter . mm, i.e. 0,043-0,051 inches see spare

parts kit To replace nozzle follow Section Steps and Section Steps

Rotate torch start button to set it’s free movement to 2-3 mm (0.08-0.12 inches).

If it is not possible to set free movement to 2-3 mm (0.08-0.12 inches), disassemble

torch (see Section , Steps 5 8-9 and adjust cathode holder position see

Section , Steps 6

see ‘What’s included’

- Open the filling neck cap.

T.

- 1.1-1 3 (

). 6.1, 1 - 3 6.6, 8 -

9.

-

-

6.1 1- , ) (

6.6 1-3, -9).

).

- Take syringe and fill it with water (

Loading...

Loading...