Terminal configurations

(If any changed, please refer to the product showing.)

③ Incorrect Control :

If the instrument has been used for a long

time, the user find the temperature is hard to rise up to the set

value, meanwhile the outsidesystem running well, there must be

something wrong with the parameters of the instrument.

The user need to re-autotuning the instrument. If the instrument

lost control, please check if the connection of the control is correct.

If external load is shorted, broken, wrong connection or compo-

nents is damaged, it will cause lost control as well.

④

Display malfunction : “UUUU”: The input signal exeed

the measured range, or check “USP” value.

ON/OFF control: ▲ Set value

←

LO HI

Alarm mode:▲ Set value △ Alarm value AL

LO HI

▲

↑

HYS

▲

Cooling

0:Deviation HI alarm

▲ △

↑

←

LO HI

1: Deviatian LO alarm

△ ▲

↑

←

LO HI

2: Absolute value HI alarm

▲ △

↑

←

LO HI

3: Absolute value LO alarm

△ ▲

↑

←

LO HI

4: Section outside alarm

△ ▲ △

HI

5: Section inside alarm

△ ▲ △

HI

Malfunction estimate

①

No Display : Check all the connection and wiring if it is all

correct. Specially pay attention to the power supply terminals and

signal input ternimals.

②

Incorrect Didplay: Check if the input signal is conformity with

the selected symbol.

For TC input, please use the relative compensation cable.

For RTD input, please use low impedence cable. The 3 wires

should at the same length.

If all above mentioned is collect , pleaase use parameter

PVF to modify.

Heating

ON OFF

Note:

All the factory setting value of deiation alarm is 1.0.

AL2 hysteresis setting value.

Range ± 90, factory setting 1.0

↓

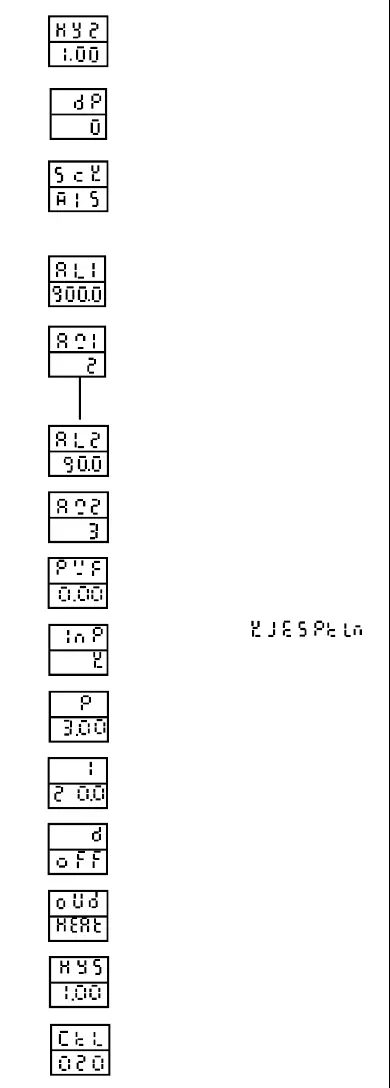

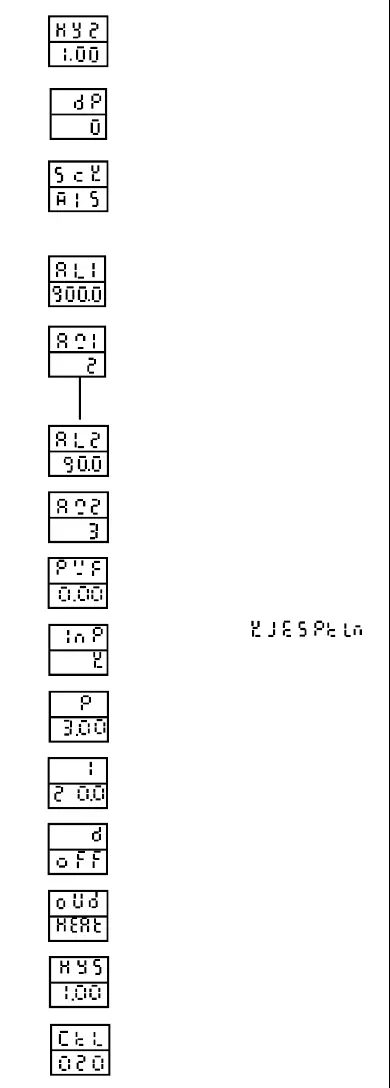

Password setting.

Factory setting 015

Decimal point setting:

0: INT display 1: One decimal point

↓

↓

↓

↓

↓

↓

↓

HOLD SET

>3 S

↓

↓

↓

------------------------------------------

AL1 set range: –1999-9999

AL1 mode:

0: Deviation HI alarm 1: Deviation LO alarm

2: PV HI alarm 3: PV LO alarm

4: SV-PV > AL1 alarm 5: SV-PV <AL1 alarm

6: TC broken alarm, 7:The first Low won’t alarm

The factory setting is 2

AL2 mode: The same as AL1.

Offset value,range: ±100.

Display valuePV = Measured value - PVF

Input signal selection

stands for K, J, E, S,Pt100,Cu50 or mA/V/mV

The factory setting is K

Proportional band (%) range 0.1-3600.

If P=OFF, it means ON/OFF control

Integral time range 0.1-3600.

I=OFF means cancel integral time.

Derivative time range 0.1-3600. D=OFF means

cancel derivative time.

AL2 set range: –1999-9999.

↓

↓

↓

↓

↓

↓

Control hysteresis, range: ± 100.

It is not available when P ≠ OFF

Control Cycle Time(adjust to best fit your process)

Recommended starting settings: Relaly = 020sec

SSR =001sec. 4-20mA = 000 sec.

Control directions: HEAt: heating

COOL: cooling

Parameter lock code setting. LcK=000

means unlocked. LcK=010 means locked.

Temperature unit. C: ℃ degree,

F: F degree.

TA6/TA8/TA9

are subject to the drawing

on the product.

Only function for 4-20mA/0-10V

means PID control;

means 4-20mA/0-10V analog output

High analog output(when available)

eg. 10-100

℃

for 4-20mA output, trH=100

Low analog output (when available)

eg. 10-100

℃

for 4-20mA output, trL=10

5

4

3

2

1 0

9

8

6

7

1

1 2

1 1

+

-

TC/mV

←

+

-

+

-

SSR

1 2

1 1

SSR

4

3

←

+

-

TA7

90-260V AC/DC

7

4

3

2

1 3

1 2

1 0

1 1

1

A

B

B

+

-

5

6

9

8

1 8

1 7

NC

NO

OUT2/AL2

T1

G

▲

7

9

T2

4

3

+

-

+

-

8

7

1 5

1 4

1 6

T1

G

▲

8

6

T2

RTD

7

6

3

2

1 3

1 2

1 1

9

1 0

1

A

B

B

AL1

4

8

1 5

1 4

5

1 6

2 4

2 3

2 2

2 1

2 0

1 9

1 8

1 7

TC

COM

OUT1

6

8

+

-

4-20mA

Application examples

1.Relay output control (for TA7)

Power supply

Heating cord

Heating

equipment

5

4

8

7

6

2

1

16

15

14

12

11

10

17

J-1

FUSE

AL1

OUT1

C

R

J

←

90-260V AC

3

13

←

P t

NO

NC

9

18

RTD

▲

↑

↑

↓

OFF ON

HYS

HY

HY

OFF ON

HY

ON OFF

OFF ON

HY

ON OFF

ON OFF ON

OFF ON OFF

SSR

SSR

4-20mA

TC

AL1

RTD

Relay

Relay

OUT1

90-260V AC/DC

SSR

AL1

Relay

OUT1

4-20mA

RTD

TA4

AL2

A

B

B

90-260V AC/DC

COM

NC

NO

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

Note:

Please operate according to the process in this instruc

tion manual. Press <</AT key2s to enter auto-tune mode,

AT lamp ON, it goes off when auto-tuned.

In most cases you should start-out by placing your con

troller in auto-tune mode. Once auto-tuned, your con

trollers should not require additional auto-tune cycle if

the environment its working in changes little. If your

controllers is being used to heat or cool a load with a large

thermal mass, then the auto-tuned values need to be re

duced by 5% -10%.

The CtL setting.In most cases our control cycle should be

set to 10-20 seconds. For heating or coolin a load with a

large thermal mass, the value should be set to 30-40

seconds. If you are using a controller with a relay, setting

longer values will help to extend the life of your relay

contacts. Unless your process dictates longer cycle times,

the value should be set to 1-3 seconds to non-relay(SSR)

controls.The value should be set to 000 if 4-20mA cur

rent controls.

7

+

8

SSR

-

Loading...

Loading...