BBTS1000/1005/1021/1060/1065/1080

Installation instruction

2

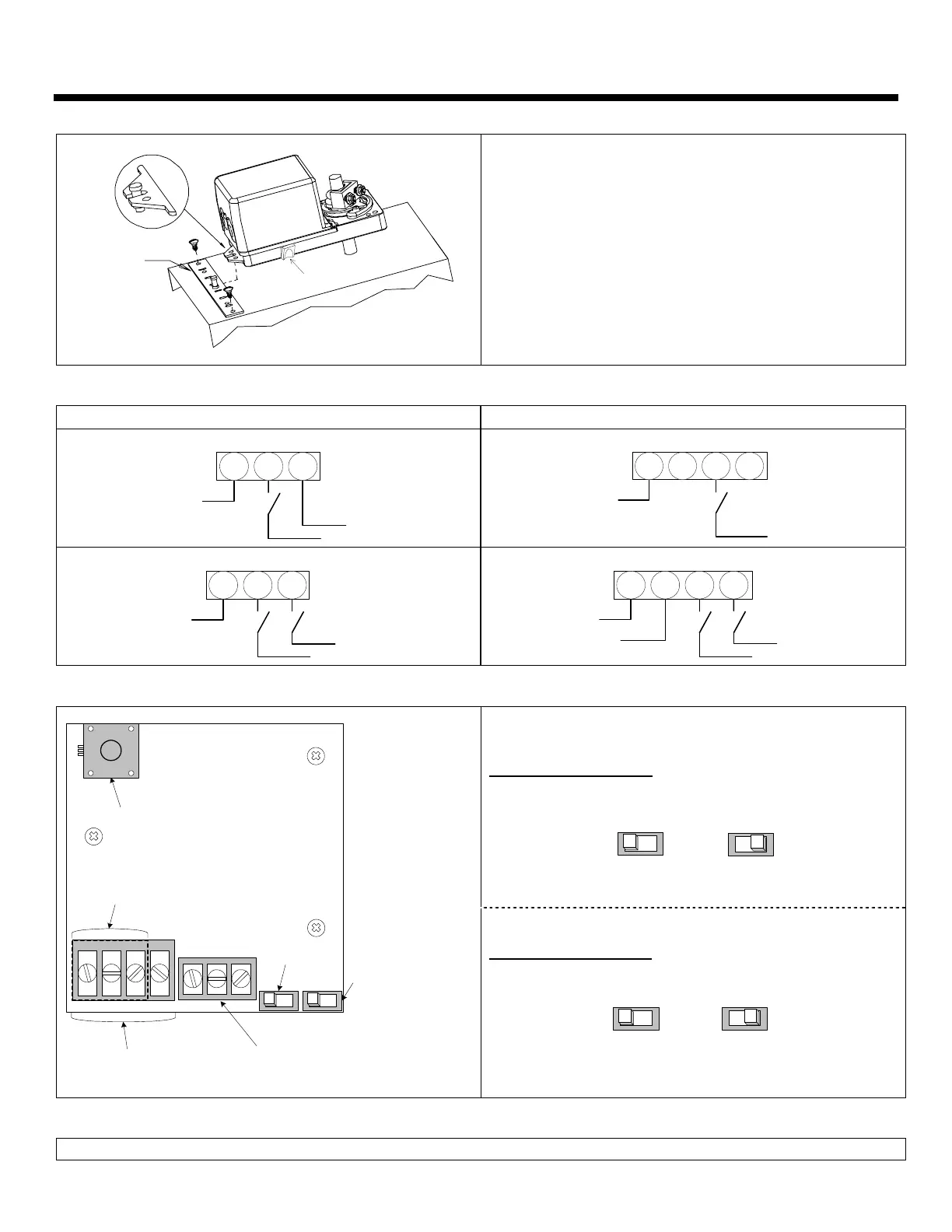

Mechanical installation

CLUTCH

MOUNTING

BRACKET

1.

Manually close the damper blades and positioned the

actuator at 0º or 90º.

2.

Slide the actuator onto the shaft.

3.

Tighten the nuts on the “U” bolt to the shaft with a 8mm

wrench to a torque of 60 in.lb. [6,7 Nm].

4.

Slide the mounting bracket under the actuator. Ensure free

movement of the slot at the base of the actuator. The

bracket pin must be placed in the mid distance of the slot.

5.

Fix the bracket to the ductwork with #8 self-tapping screws.

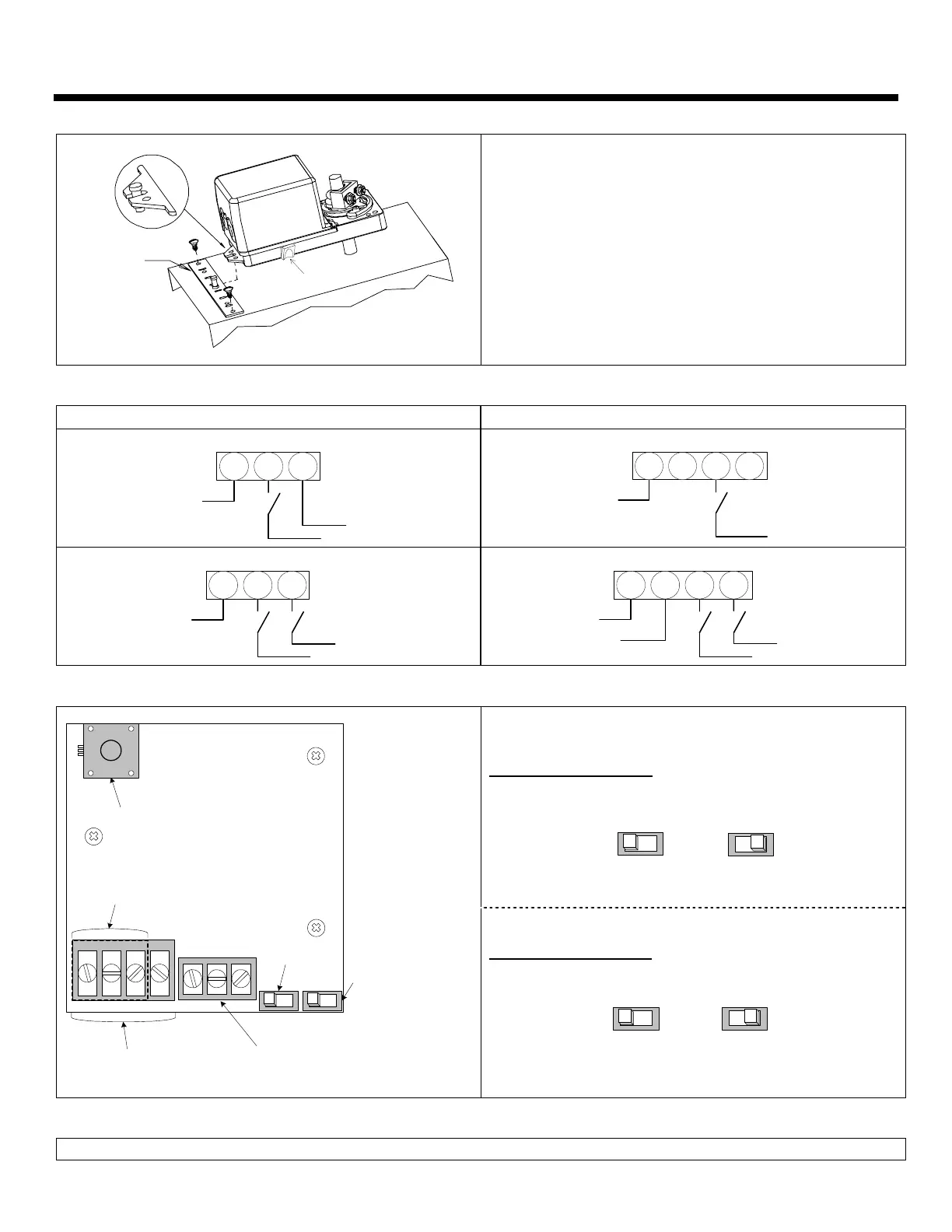

Wiring Diagrams

Models BBTS1000, 1005 & 1021 Models BBTS1060, 1065 & 1080

3 wire / 2 position (ON-OFF)

COMMON

DRIVE CW

SUPPLY

1 2 3

2 wire / 2 position

(ON-OFF)

COMMON

DRIVE CW

1 2 3 4

3 wire / 3 point floating

COMMON

DRIVE CW

DRIVE CCW

1 2 3

4 wire / 3 point floating

COMMON

SUPPLY

DRIVE CW

DRIVE CCW

1 2 3 4

PC Board

Dip switch settings

Rotation direction (SW1)

CW

(0 to 90º)

CCW

(90 to 0º)

SW2

Potentiometer

Only on model 1005, 1065

BT060VAV

1 2 3 4

Feedback or switches terminal

Only on model 1005, 1021,

1065 & 1080

Rotation

direction

6 7 8

Fail safe direction

Only on model

1060, 1065 & 1080

SW1

Terminal 4 pins

Only on model

1060, 1065 & 1080

Terminal 3 pins

Only on model

1000, 1005 & 1021

Fail safe direction (SW2)

Fail safe

return at 0º

Fail safe

return at 90º

Stroke adjustment

To adjust the stroke, move the adjustment screws at the desired position.

Loading...

Loading...