Mounting Instructions EN

MA-CFB_BEARING 4.4 – 02/2020 8

Deep groove ball bearing

with sheet metal flange sheet metal strut fastening

RER 11-0200/-0710

RER 12-0200/-0710

RER 15-0400/-0710

(Page 1 of 1)

Notes

The greased deep groove ball bearings sealed on both sides are designed for a nominal service life (L

10h

according to DIN ISO

281-1) of 20,000 respectively 40,000 operating hours. If it is required to change the bearings, the safety instructions

stipulated in the RZR / RER operating instructions must be followed without fail!

General information

To expose the fan bearings, various dismounting work (e.g. disconnection from the mains, belt drive, protective and

monitoring devices, ducts), must be performed in compliance with the safety and accident protection regulations and the local

and structural conditions.

0200/-0355

0400/-1000

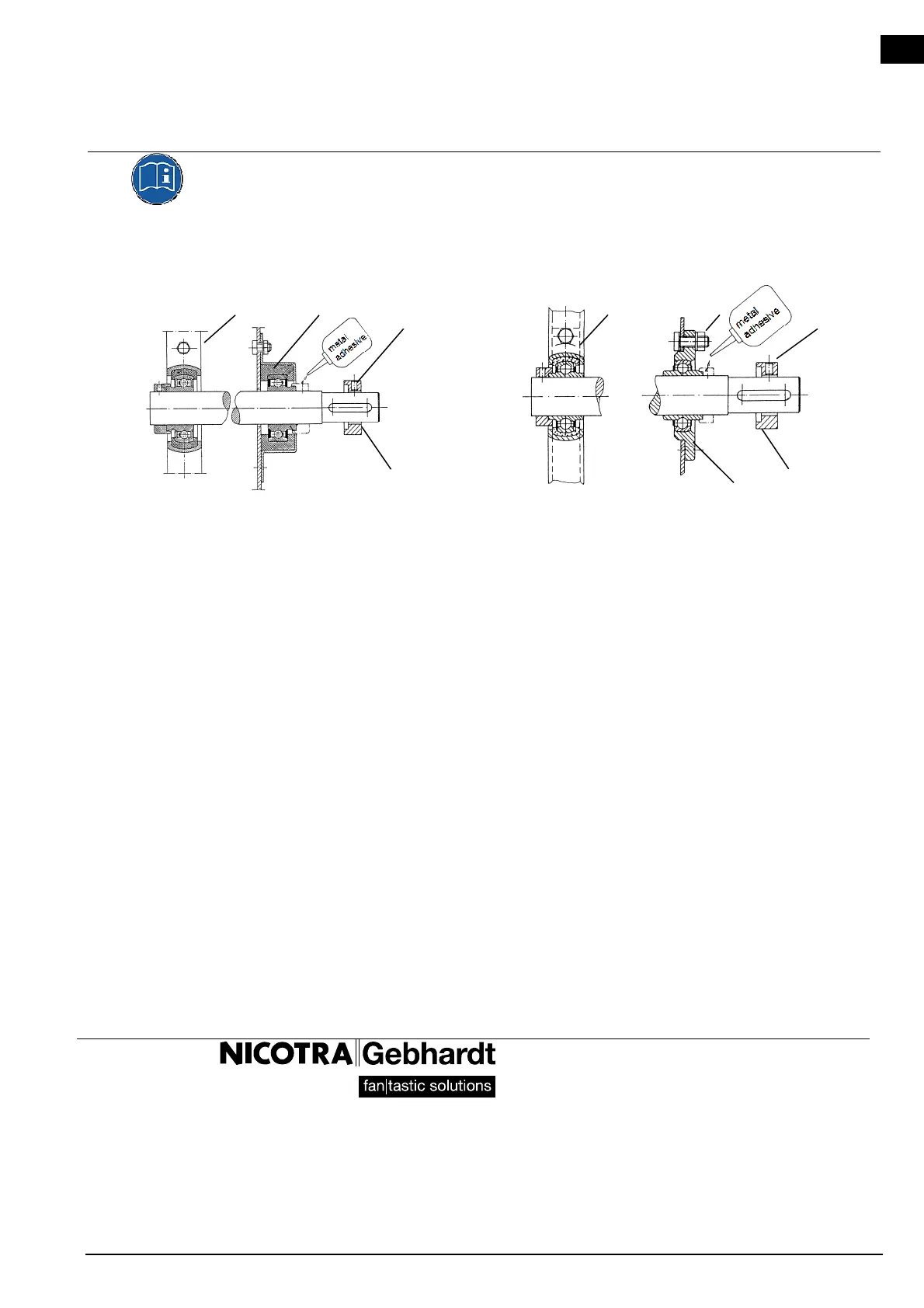

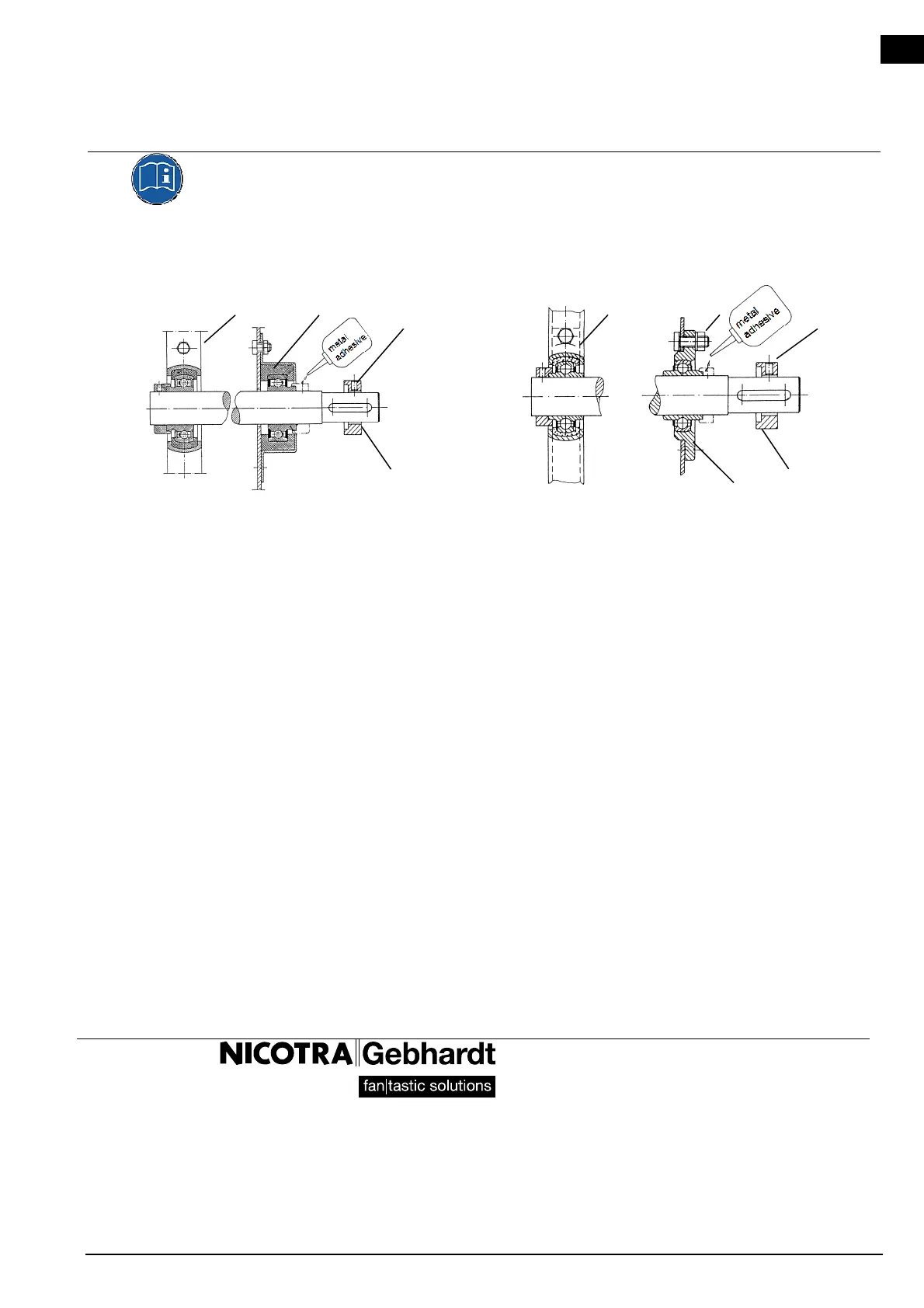

Dismounting the bearing

1. Unscrew the locking screw (1), unscrew the eccentric clamping ring (2) against the direction of rotation of the running

wheel and remove it.

Bearing on intake side (0200/-1000)

2. Dismount profile strut support (3).

3. Remove rubber insulating ring and pull the bearing off the inner ring with a suitable tool (Warming the bearings up to

200°C facilitates dismounting substantially, is however not necessarily required).

Bearing on drive end (0200/-355)

4. Dismount the flange housing (4), remove the rubber insulating ring and pull off the bearing

Bearing on drive end (0400/-1000)

5. Loosen the nuts of the screws (5). Screw 2 screws M10×30 into the empty drill holes M10 in the housing, push back the

housing so that a three-armed extractor can be set on it. Set the extractor on the

cast housing (6) and pull off the cast housing with the bearing.

Mounting the bearing

1. Clean the seat of the roller bearing on the shaft and the inner ring of the bearing thoroughly and remove the grease from

them with fat dissolving agents (petroleum benzine, etc.).

2. Push pre-assembled supporting unit on the shaft and fasten it to the housing. Apply drops of adhesive to the seat of the

bearing.

3. Adjust the air gap between the fan wheel and the inlet nozzle.

After adjustment apply drops of adhesive between the inner ring of the bearing and the shaft as shown in the drawing.

4. Push the eccentric clamping ring (2) on the shaft and tighten it with the bearing in the direction of rotation of the running

wheel with a light jarring blow, tighten the locking screw (1). The hardening time of the adhesive depends on the

temperature, it takes approx. 24 h at +20°C.

Nicotra Gebhardt GmbH

Gebhardtstrasse 19-25

74638 Waldenburg, Germany

Telefon +49 (0)7942 1010

Telefax +49 (0)7942 101170

E-Mail info@nicotra-gebhardt.com

www.nicotra-

ebhardt.com

1

2

2

3

3

4

5

6

1

Loading...

Loading...