10

8.

Fitting the tank

1. Place the tank on the lower control handle

holder

2. Fix it in place with the upper holder

3. Attach the cable to the left hand lever on the

control handle

4. Connect the liquid hose to the tank and insert it

to the side of the motor

9.

Fitting shampoo accessory

(only for the 300 MINI, 400 EL, 401 STANDARD /

402 VARIO)

1. Place the tank on the lower control handle

holder

2. Fix it in place with the upper holder

3. Attach the cable to the left hand lever on the

control handle

4. Connect the liquid hose to the tank and insert it

to the side of the motor

5. Mount the shampooing equipment and the fan

in the tank

6. Attach the shampoo nozzle under the machine

10.

Maintenance and service

1. Always withdraw the mains plug before begin-

ning servicing work.

2. Regularly check the mains plug and connecting

cable for functional safety.

3. Only trained electricians may work on electrical

components.

4. Clean the accessory

5. Regularly clean the spray device with water after

use.

6. Regularly wipe down the machine with a damp

cloth.

7. After work:

• Do not leave the machine resting on the ac-

cessory

• This prevents them from becoming distorted

• Distortions cause uneven running

• Check the dust bag and filter

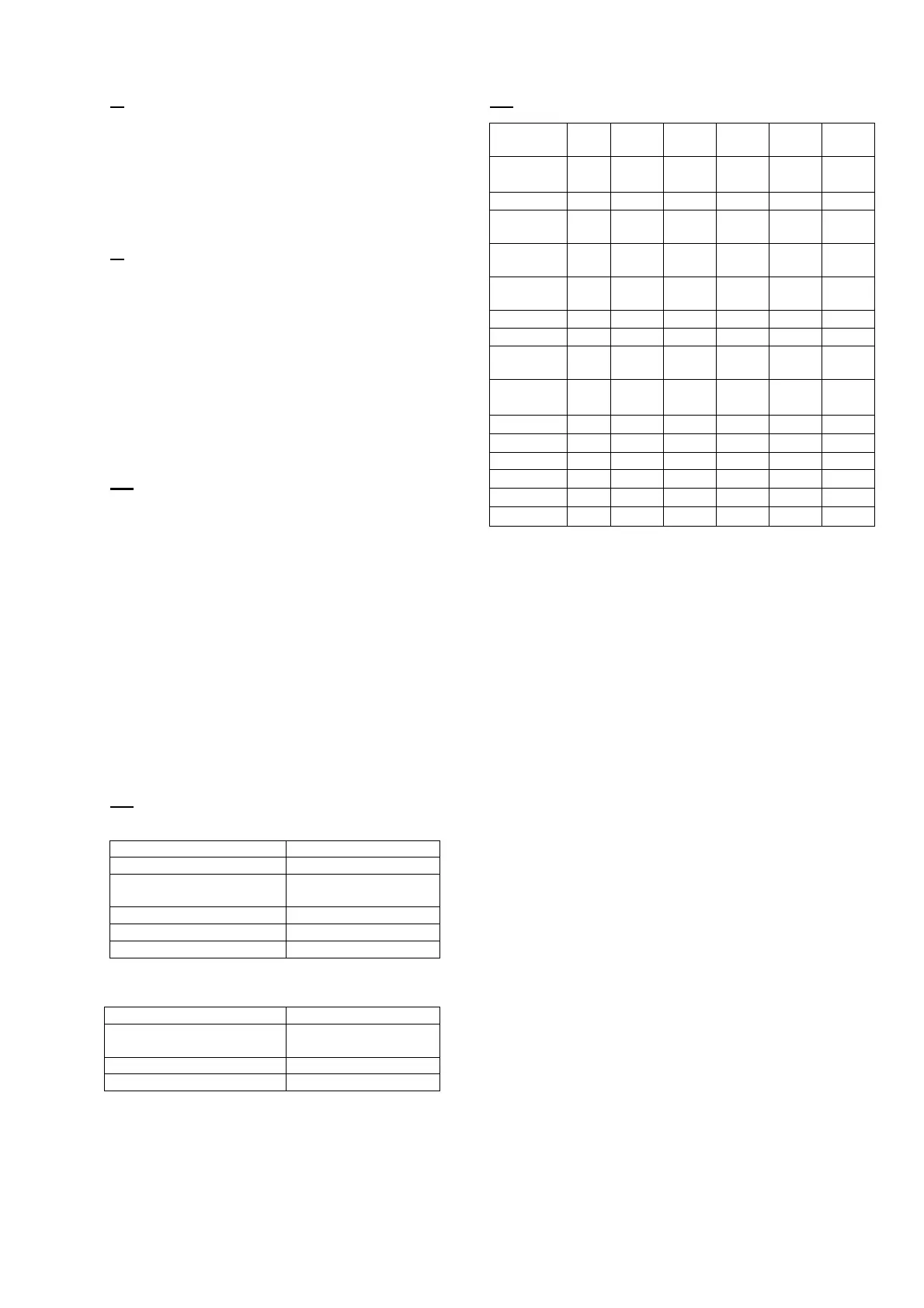

11.

Fault-finding and rectification

1. The machine does not start

Cause Remedy

Mains plug not inserted Insert properly

Motor overload protection

has switched the motor off

Let the machine cool

down and start it again

Faulty connecting cable Exchange

On/off switch faulty Exchange

Faulty capacitor Exchange

2. Machine runs roughly

Cause Remedy

Dirty brush, pad or working

tool

Clean tools

Working tool not centred Centre it again

Working tool worn out Exchange

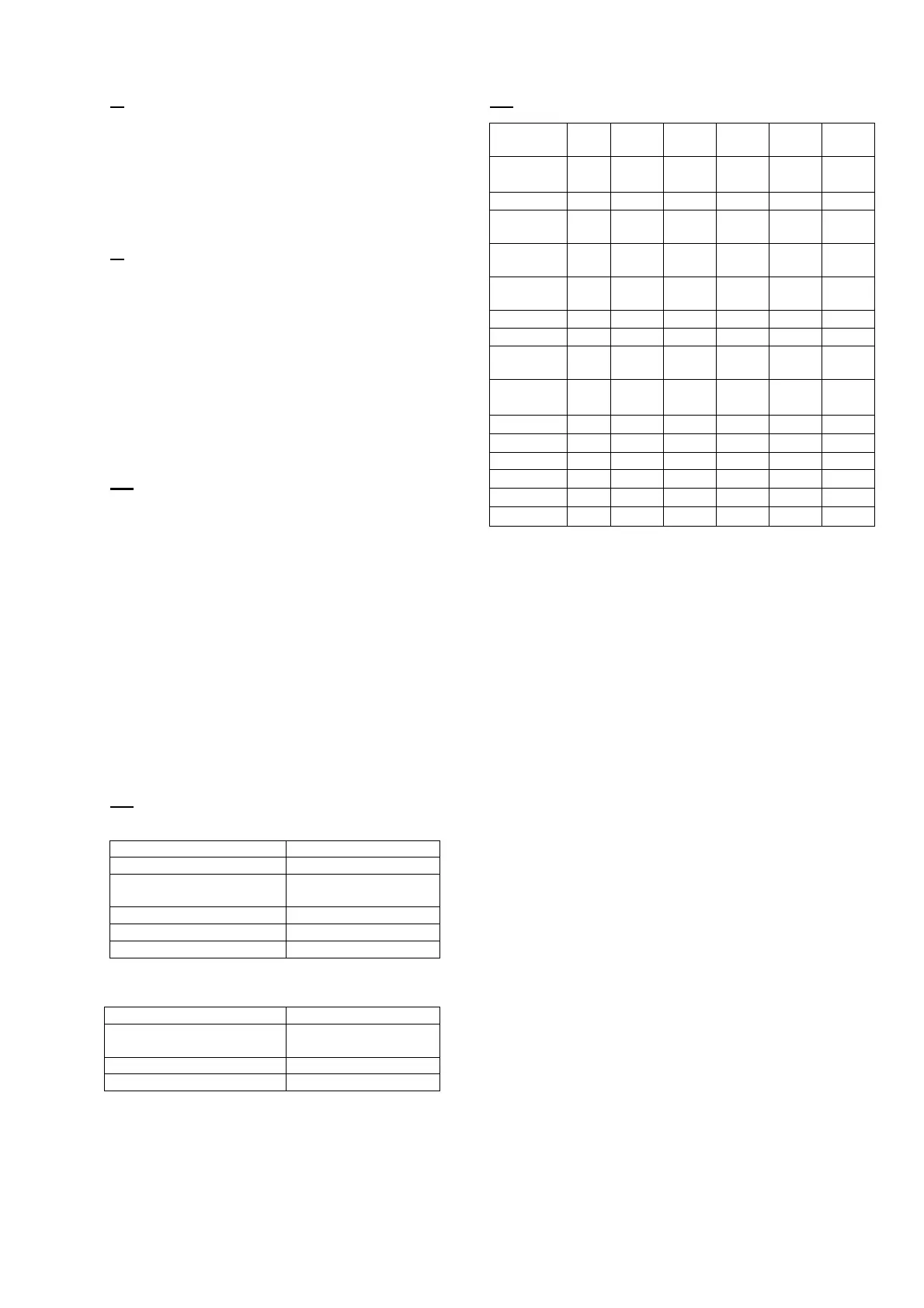

12.

Technical Data

Type

300

MINI

400

EL

401

STAND

402

VARIO

405

SUPER

Voltage V 220-240 220-240 110/

220-240

220-240

110/

220-240

Frequency Hz 50 50-60 50-60 50-60 50-60

Protection

class

I I I I I

Protection

grade

IP 44 44 44 44 44

Drive motor W 600 1200 1200 1300/

1600

1600

Brush - ø mm 330 430 430 430 430

Pad - ø mm 330 430 430 430 430

Rotation

speed

r.p.m. 165 165 165 165/330

400

Working

pressure

g/cm² 37 32 37 46 40

Torque Nm 32 46 46 50/37 37

Cable length m 12 12 12 12 12

Noise level dB(A) 58 58 58 58 58

Weight kg 22 30 34 42 37

Vibration m/s 2,5 2,5 2,5 2,5 2,5

CE testing yes yes yes yes yes

Loading...

Loading...