EM-118

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ40DE]

ENGINE UNIT

• If out of the standard, measure the main bearing oil clearance. Then use undersize bearing.

CRANKSHAFT PIN JOURNAL DIAMETER

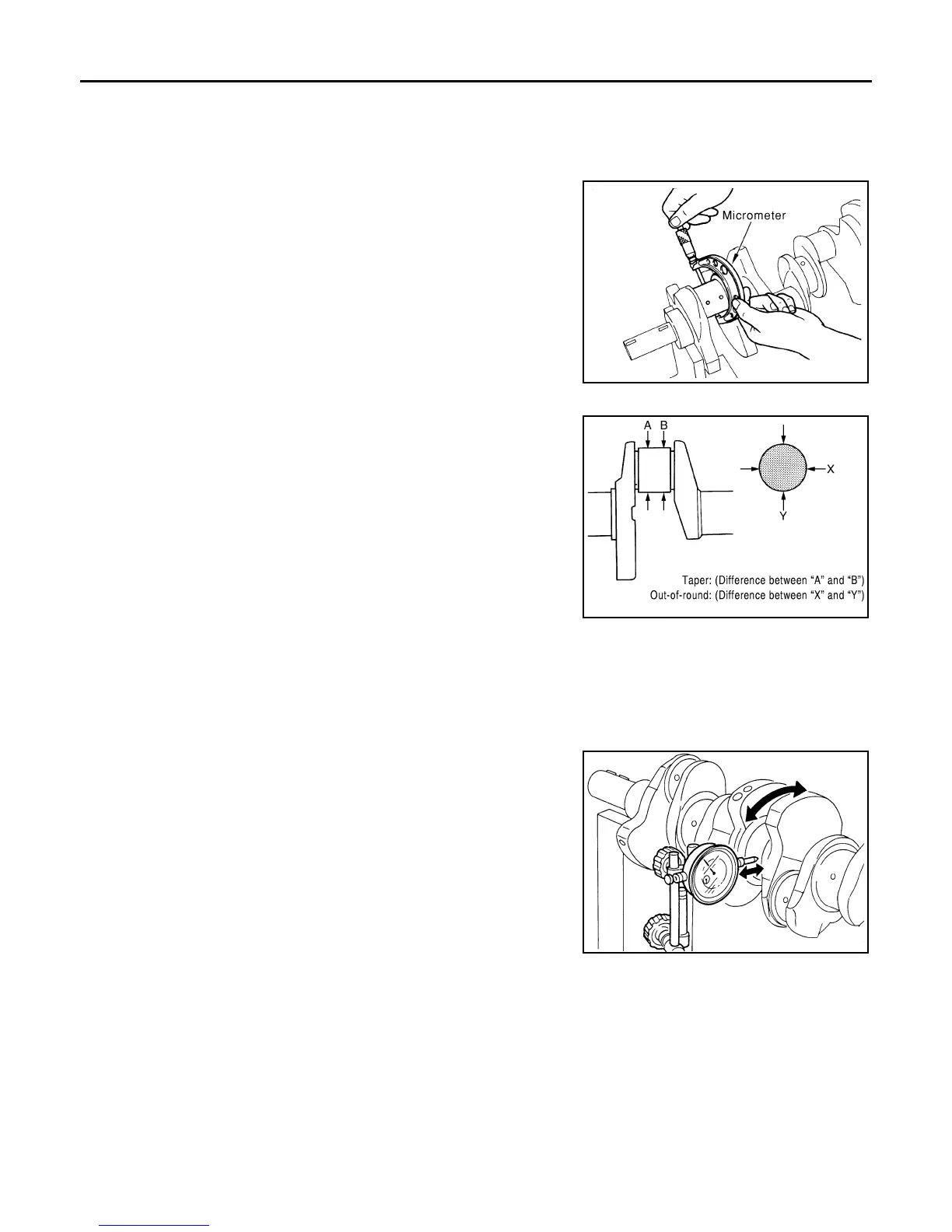

• Measure the outer diameter of crankshaft pin journal with

micrometer.

• If out of the standard, measure the connecting rod bearing oil

clearance. Then use undersize bearing.

OUT-OF-ROUND AND TAPER OF CRANKSHAFT

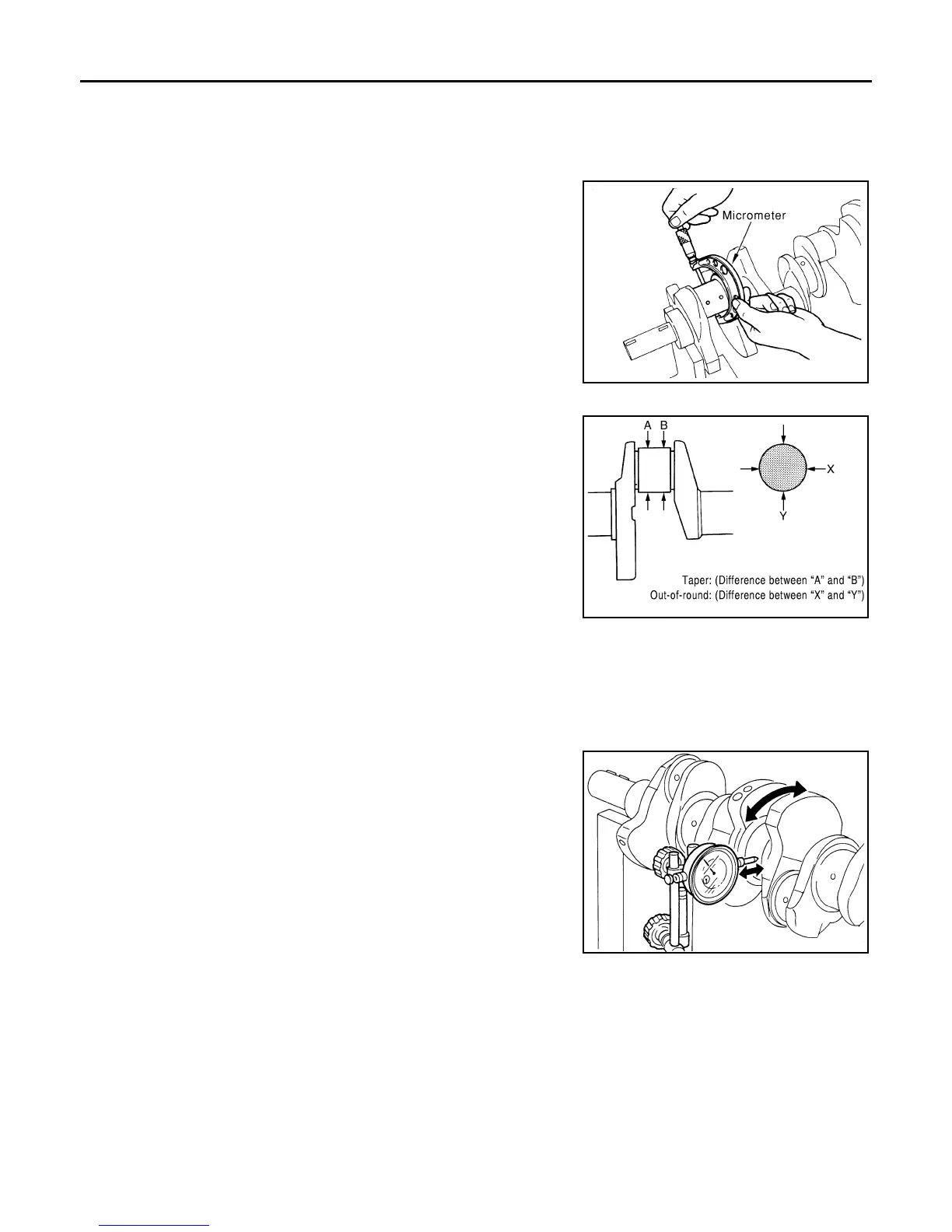

• Measure the dimensions at four different points as shown on each

main journal and pin journal with micrometer.

• Out-of-round is indicated by the difference in the dimensions

between (X) and (Y) at (A) and (B).

• Taper is indicated by the difference in the dimensions between (A)

and (B) at (X) and (Y).

• If the measured value exceeds the limit, correct or replace crankshaft.

• If corrected, measure the bearing oil clearance of the corrected main journal and/or pin journal. Then select

the main bearing and/or connecting rod bearing.

CRANKSHAFT RUNOUT

• Place V-block on precise flat table, and support the journals on

both ends of crankshaft.

• Place dial indicator straight up on the No. 3 journal.

• While rotating crankshaft, read the movement of the pointer on dial

indicator. (Total indicator reading)

• If it exceeds the limit, replace crankshaft.

CONNECTING ROD BEARING OIL CLEARANCE

Method by Calculation

Standard : 69.951 - 69.975 mm (2.7540 - 2.7549 in) dia.

Standard : 53.956 - 53.974 mm (2.1242 - 2.1250 in) dia.

PBIC0127E

Limit:

Out-of-round [Difference between (X) and (Y)]

: 0.002 mm (0.0001 in)

Taper [Difference between (A) and (B)]

: 0.002 mm (0.0001 in)

SBIA0535E

Standard : Less than 0.05 mm (0.002 in)

Limit : 0.10 mm (0.0039 in)

SEM346D

Revision: January 2013 2013 Xterra

Loading...

Loading...