EM-38

< REMOVAL AND INSTALLATION >

[VQ40DE]

OIL PAN AND OIL STRAINER

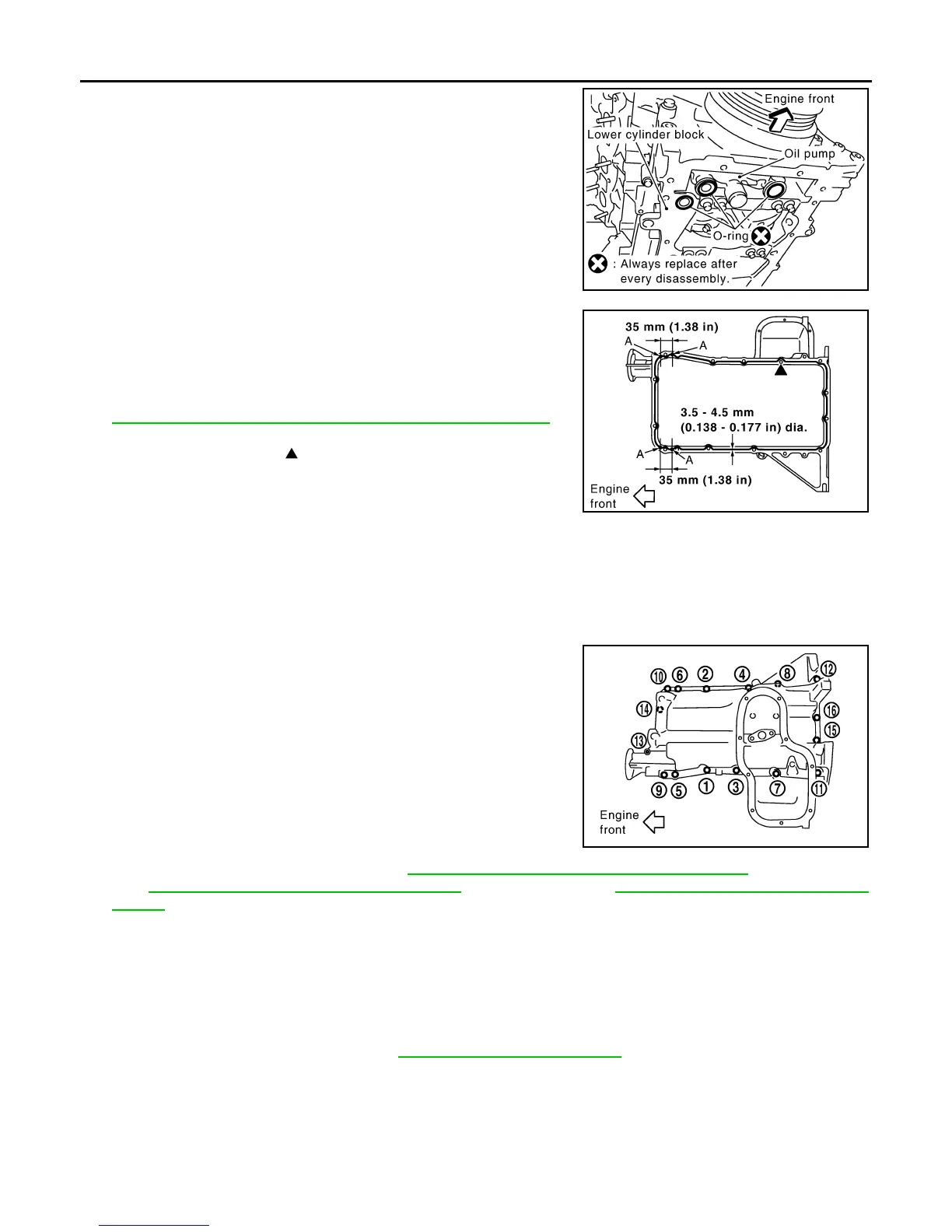

b. Install new O-rings on the bottom of lower cylinder block and oil

pump.

CAUTION:

• Do not reuse the three O-rings.

• Install a new O-ring in the upper oil pan and two new O-

rings in the front cover.

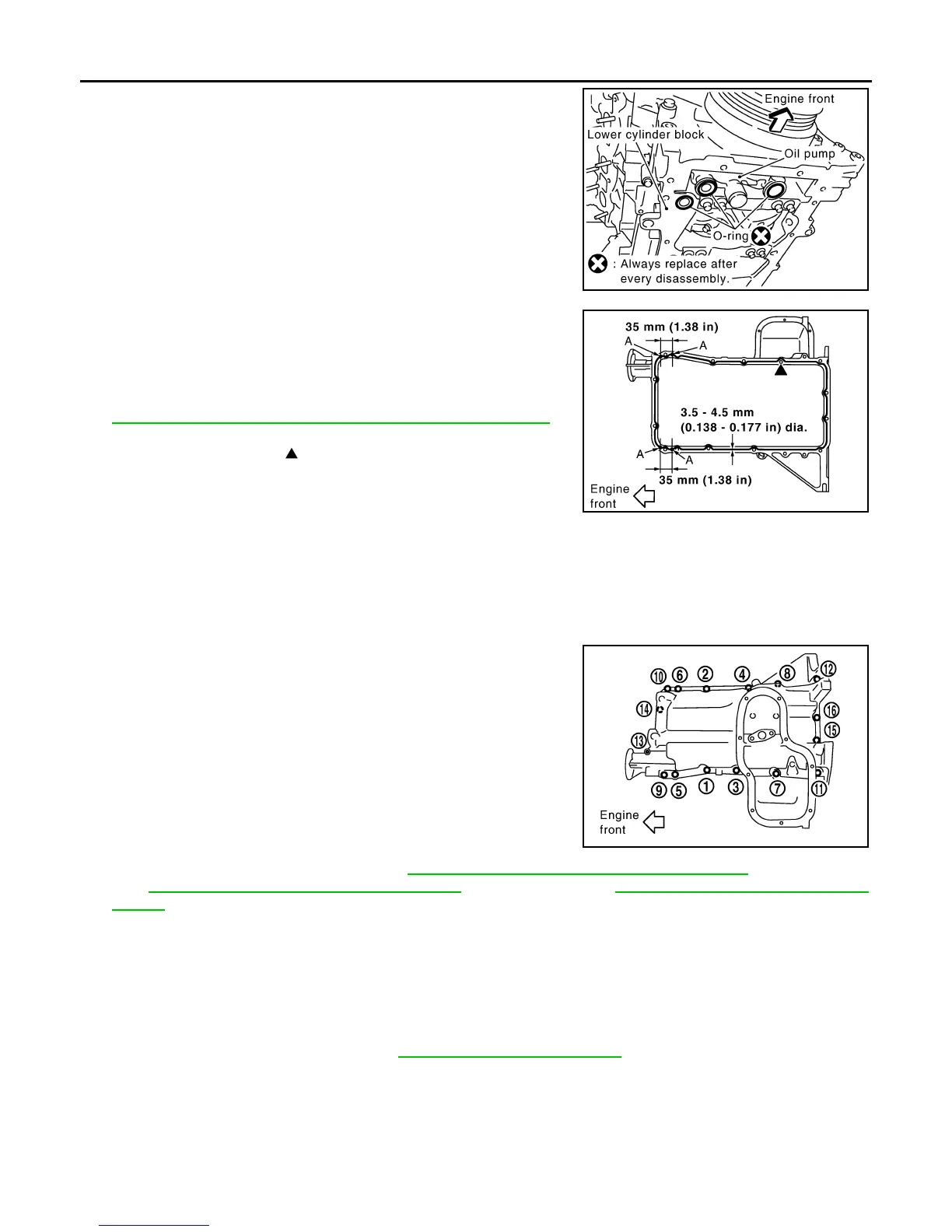

c. Apply a continuous bead of liquid gasket using Tool to the lower

cylinder block mating surfaces of oil pan (upper) as shown.

Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-17, "Recommended Chemical Products and Sealants"

.

CAUTION:

• For bolt holes with mark, apply liquid gasket outside

the hole.

• Apply a bead of 4.5 to 5.5 mm (0.177 to 0.217 in) in diame-

ter to area (A).

• Installation should be done within 5 minutes after coating.

d. Install oil pan (upper).

CAUTION:

• Do not reuse the three O-rings.

• Install a new O-ring in the upper oil pan and two new O-rings in the front cover.

• Install avoiding misalignment of both oil pan gaskets and O-rings.

• Tighten oil pan (upper) bolts in numerical order as shown.

• There are two types of bolts.

e. Tighten transmission joint bolts. Refer to TM-21, "Removal and Installation from Vehicle"

(4WD M/T mod-

els), TM-248, "Removal and Installation (2WD)"

(2WD A/T models), TM-250, "Removal and Installation

(4WD)" (4WD A/T models).

2. Install oil strainer to oil pan (upper).

3. Installation of the remaining components is in the reverse order of removal.

CAUTION:

Do not fill the engine with oil for at least 30 minutes after oil pan is installed.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-13, "Fluids and Lubricants"

.

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

NOTE:

PBIC2885E

Tool number : WS39930000 ( — )

PBIC2886E

M8 × 100 mm (3.97 in) : 7, 11, 12, 13

M8 × 25 mm (0.98 in) : All except the above

PBIC2887E

Revision: January 2013 2013 Xterra

Loading...

Loading...