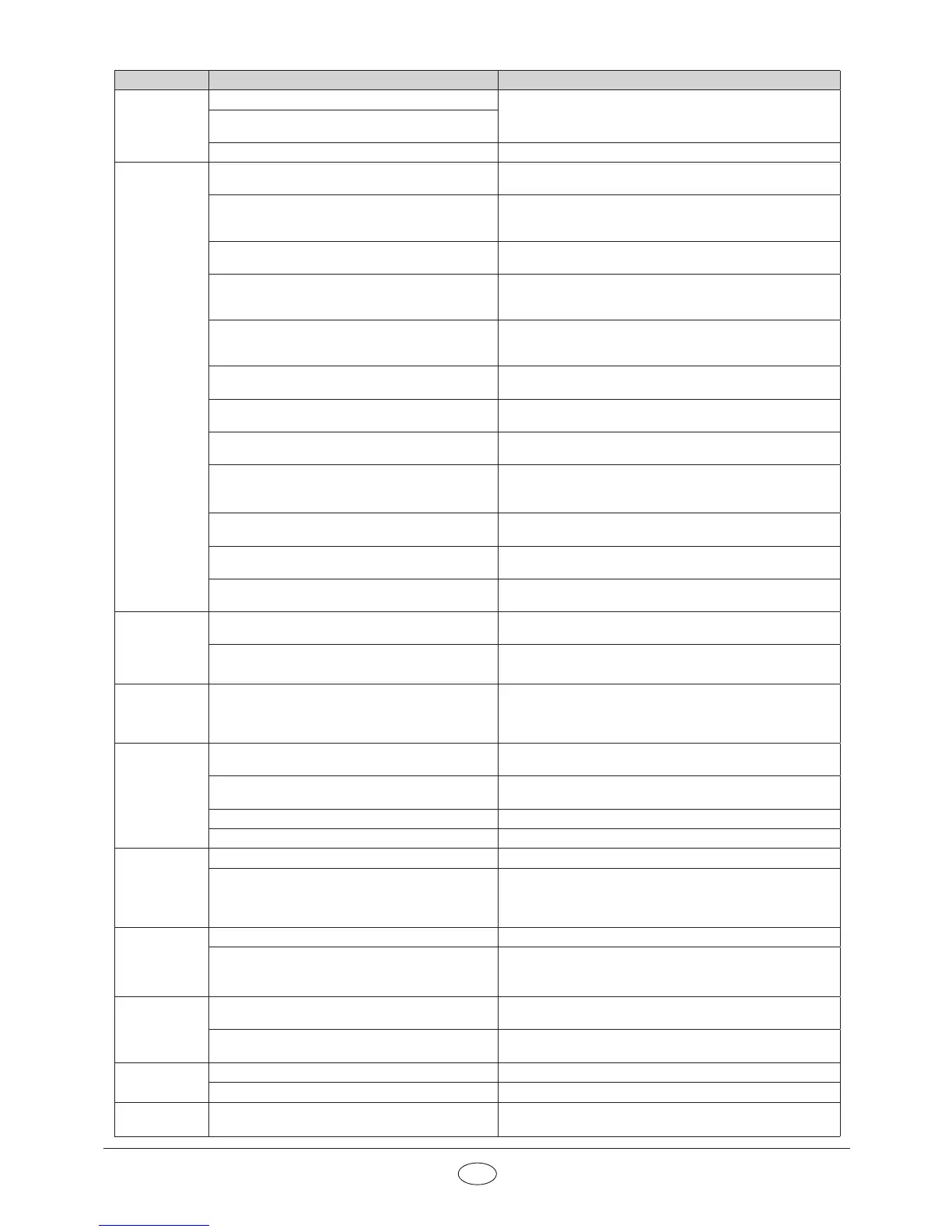

Some advice in case of combustion problems

Error Explanation Solution

No draught

The chimney is blocked

Contact a chimney sweeper / dealer for more information or clean

the ue, smoke bae and burn chamber.

The ue is sooty or there is accumulated soot on the

smoke bae

The smoke bae is wrongly positioned Verify the assembly of the smoke bae - see assembly instructions.

The stove

release smoke

when lighting

the re and

during combus-

tion

Downdraught in the room caused by no draught, that the

house is too “air tight”.

Light the re with an open window. If this helps, more/bigger vents

must be installed in the room.

Downdraught in the room – caused by extractor and/or

central ventilation system that pulls too much air out of

the room.

Turn o/regulate extractor and/or other ventilation. If this helps,

more vents must be installed.

The ues from two replaces/stoves are connected to

the same chimney at the same height.

One ue must be repositioned. The height dierence of the two ue

pipes must be of at least 30 cm.

The ue is in a declining position from the smoke dome

to the chimney.

The ue must be moved so that there is an inclination of at least

10º from smoke dome to chimney. Possibly install a smoke suction

device*.

The ue is too far into the chimney.

The ue must be reconnected so that it does not enter into the

chimney but ends 5 mm before the chimney inner wall. Possibly

install a smoke suction device*.

Soot hatch in the basement or attic that is open and thus

creating a false draught.

Soot hatches must always be closed. Hatches that are not tight or

are defected must be changed.

Damper/top draught vents or doors on replaces that are

not in use are open and create a false draught.

Close damper, doors and top draught vents on replaces that are

not in use.

An open hole in the chimney after that a replace has

been removed, thus creating a false draught.

Holes must be completely sealed o with masonry.

Defect masonry in the chimney, e.g. it is not airtight

around the ue pipe entry and/or broken partition inside

the chimney creating a false draught.

Seal and plaster all cracks and sites that are not tight.

The cross-section in the chimney is too large which

results in no or very low draught.

The chimney must be retted, possibly install a smoke suction

device*.

The cross-section in the chimney is too small and the

chimney cannot carry out all the smoke.

Change to a smaller replace or build new chimney with a larger

cross section. Possibly install a smoke suction device*.

The chimney is too low and hence a poor draught.

Increase the height of the chimney and/or install a chimney cap/

smoke suction device*.

The stove

releases smoke

inside when

it is windy

outside.

The chimney is too low in relationship to the surrounding

terrain, buildings, trees etc.

Increase the height of the chimney and/or install a chimney cap/

smoke suction device*.

Turbulence around the chimney due to the roof being

too at.

Increase the height of the chimney and/or install a chimney cap/

smoke suction device*.

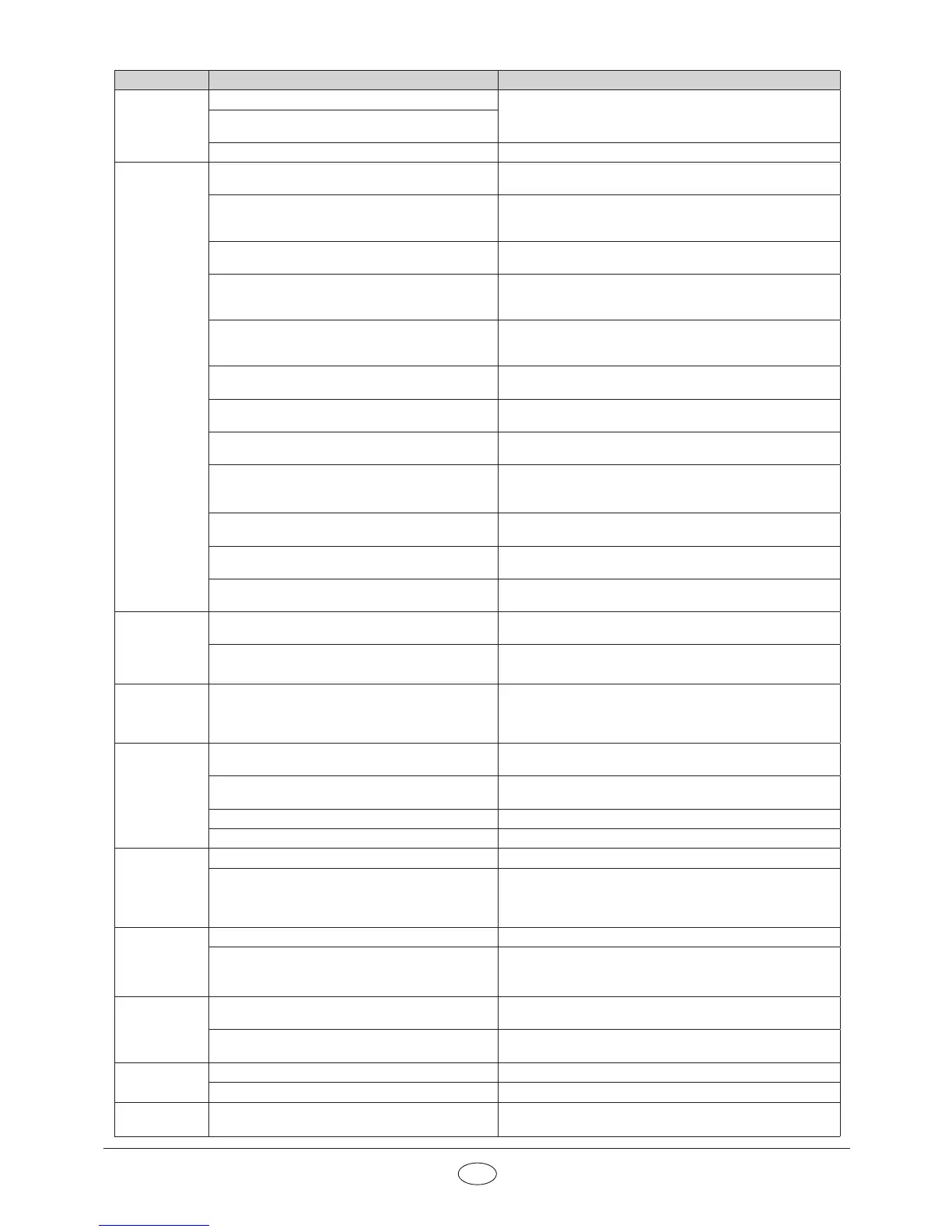

The stove does

not heat suf-

ciently.

The combustion receives too much oxygen due to a

leakage under the lower border of the stove or too strong

chimney draught. Dicult to regulate the combustion and

the wood burn up too quickly.

Any possible leakage must be sealed o. A draught regulator or

possibly a damper can reduce the chimney draught. NB! A leakage

of only 5 cm2 is enough for 30% of the heated air to disappear.

Too much

draught

The smoke buer is wrongly positioned.

Verify the positioning of the smoke buer – see assembly instruc-

tions.

In case of using oven-dried wood, this requires less air

supply than when using normal wood.

Turn down the air supply.

The gaskets around the door are worn and totally at. Replace the gaskets, contact your dealer.

The chimney is too large. Contact chimneysweeper or other professional for more details.

The glass is

sooty

The wood is too wet. Only use dry wood with a humidity of maximum 20%.

The air vent control is closed too tightly.

Open the air vent control to add air to the combustion. When new

wood logs are inserted all vent controls should be completely

opened or the door slightly opened until the ames have a good

take on the wood.

White glass

Bad combustion (the temperature is too low) Follow the guidelines in this user guide for correct combustion.

Using wrong material for combustion (such as: painted

or impregnated wood, plastic laminate, plywood etc)

Ensure to use only dry and clean wood.

Smoke is relea-

sed when the

door is opened

A levelling out of pressure occurs in the burn chamber.

Open the air vent control for about 1 min before opening the door

– avoid opening the door too quickly.

The door is opened when there is a re in the burn

chamber.

Open the door carefully and/or only when there is hot ember.

White smoke

The combustion temperature is too low. Increase the air supply.

The wood is humid and contains water damp. Ensure to use only dry and clean wood.

Black or grey/

black smoke

Insucient combustion. Increase the air supply.

Loading...

Loading...