MODEL#:

TU40

FEATURES:

• Rea l -Ti me Cl o c k Fa c e w i th

OFF/ AUTO/ ON Override Switch

•

Captive Trippers

• 15 Minute Intervals

• NEMA 3R Plastic Indoor/ Outdoor

Enc l o sur e

•

Green LED Indicates power

• Red LED indicates load status

•

40 AMP DPDT Contacts

• 8-18 AWG Screw Terminals

OUTPUT:

DPDT, Dry Contacts (Unpowered) all in one may also be used for SPST, SPDT, DPST

CONTACT RATINGS: NO CONTACTS:

40 AMPS RESISTIVE @ 120-277 VAC 60Hz

30 AMPS INDUCTIVE @ 120-277 VAC

1HP, 30FLA, 90LRA @ 120 VAC

2HP, 20FLA, 60 LRA @ 240 VAC

30 AMPS BALLAST @ 120 VAC

20 AMPS BALLAST @ 277 VAC

15 AMPS TUNGSTEN @ 120 VAC

20 AM PS RESISTIVE @ 2 8 VDC

720 VA PILOT DUTY @ 120-240 VAC

30 AMPS MAX ABOVE 104°F

NC CONTACTS:

30 AMPS RESISTIVE @ 120-277 VAC 60Hz

15 AMPS INDUCTIVE @ 120-277 VAC

1/ 4HP, 12FLA, 30 LRA @ 120 VAC

1/ 2HP, 12FLA, 33 LRA @ 250 VAC

10 AMPS BALLAST @ 120-277 VAC

290 VA PILOT DUTY @ 120VAC

360 VA PILOT DUTY @ 240 VAC

OPERATING TEMP:

-31°F to 116°F (-35°C to +47°C) Relative Humidity is 10% to 95%

TIM ER SUPPLY:

120/ 208-240/ 277VAC, 60Hz Detects voltage automatically (NO DIP SWITCH SETTING REQUIRED)

POW ER CON SUMPTION:

6VA Max @ 120VAC

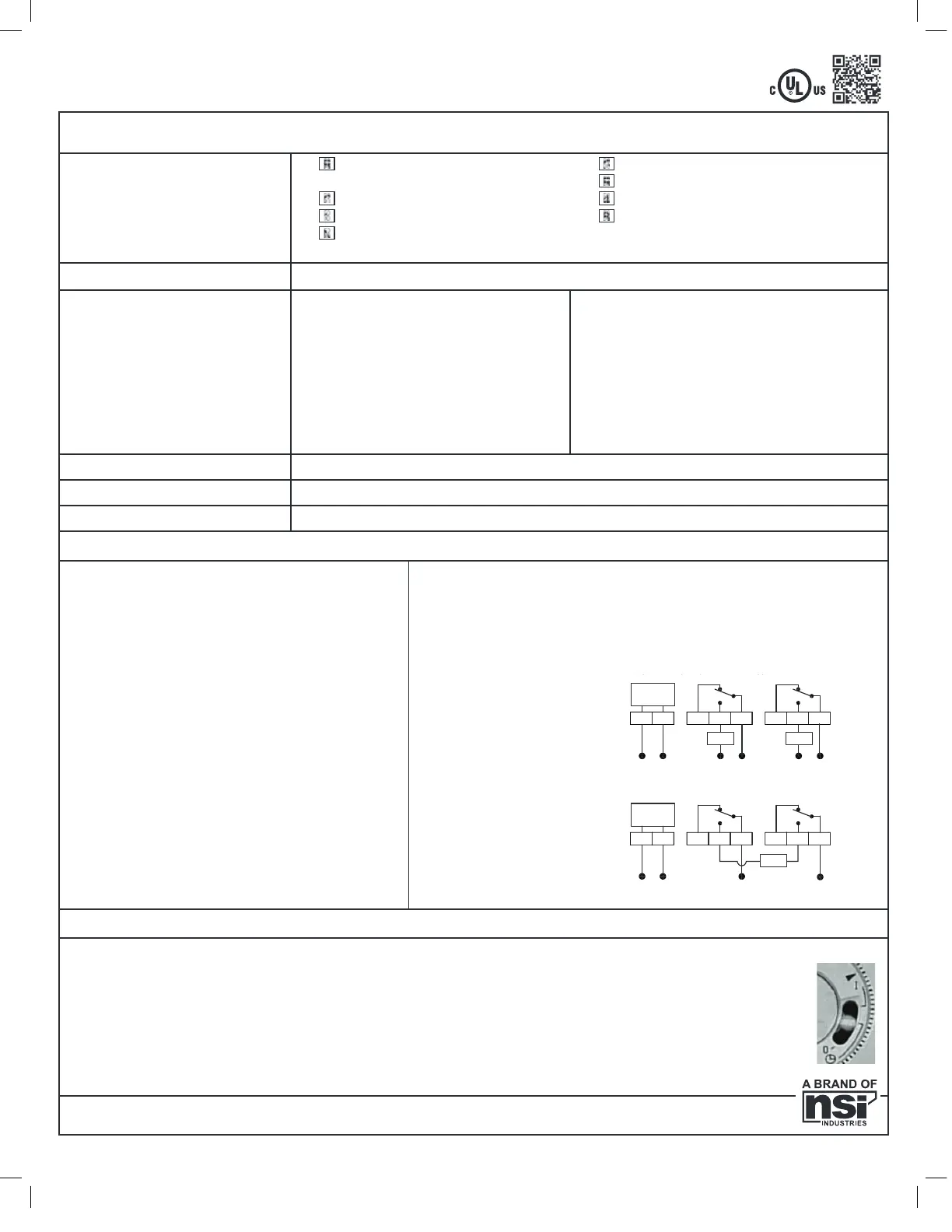

INSTALLATION & WIRING DIAGRAMS

UNIT IS TO BE INSTALLED BY A

LICEN SED ELECTRI CIA N

1. Mount the enclosure at eye level using screws or

other suitable fastening device. Bring supply and

load wires in through bottom or side knockouts.

2. Wire as per typical wiring diagram below, and

follow all local and NEC codes.

3. To ensure proper connection to the terminal

block, turn the screw fully counterclockwise

before inserting wires. Firmly fasten the screw

terminal

SETTIN G ON/ OFF TIM ES

1. The timer has 96 tabs which can turn loads ON or OFF every 15 minutes. Push tabs outward to turn the load ON,

and pull them inwards to turn the load OFF for the desired ON and OFF durations.

2 . Rotate di a l clockw i se to set the ti me. A li gn ti me w i th arrow. DO N O T ATTEM PT TO SET THE TIM E BY USIN G

THE M IN UTE HA N D IN THE CEN TER O F THE DIAL.

3. Automatic operation: To execute the programmed schedule, set the selector switch to the center position.

(Shown by clock symbol)

4. MANUAL OVERRIDE: Set the switch to the “ I” position to turn the load permanently ON.

Set the switch to the “0” position to turn the load permanently OFF.

877.230.7874 • www.nsiindustries.com

UNIVERSAL MULTI-VOLTAGE

ELECTRO M ECHA N I CA L TIM E SW ITCH

Use copper wire AWG 8-18 suitable for 90°C. WIRING TO COMPLY WITH ALL LOCAL AND NA-

TIONAL ELECTRICAL CODES. Bonding between conduit connection is not automatic and must

be provided as part of the installation. THE ENCLOSURE MUST BE PROPERLY GROUNDED.

Minimum 10.6 lb. in. torque required at the terminals to ensure proper connections. Strip the

supply and load wires to 1/ 2” .

LI-831( C)

PATENT PENDING

N

LN

NCNOC

LN

NCNOC

LN

Typical Wiring Diagram, 120 VAC Appl i cat i on

HN

L1 L2

NCNOC

L1

NCNOC

L2

TIMER

SUPPLY

TIMER

SUPPLY

LOAD LOAD

LOAD

H

Typical Wiring Diagram, 208-240 VAC Applicat ion

Typical Wiring Diagram, 120/ 277VAC Appl icat ion

Loading...

Loading...