Laying

the

Machine

Up

for

the

Winter

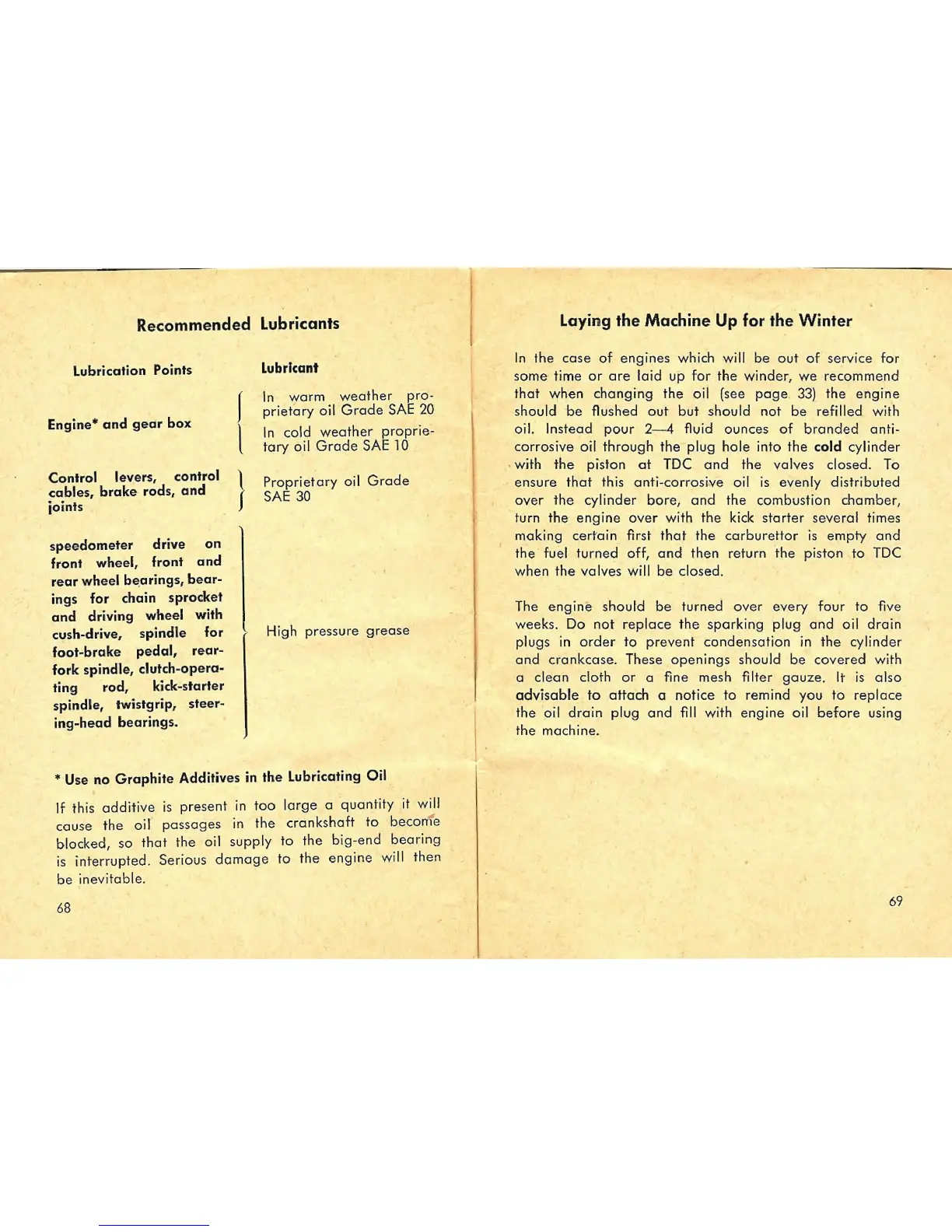

Recommended Lubricants

Lubrication Points

Lubricant

In

warm

weather

pra-

f

prietary oil

Grade

SAE

20

Engine"

and

gear

box

In

cold

weather

praprie-

t

tary

oil

Grode

SAE

10

Control levers, control

Proprietary

oil

Grade

cables,

brake

rods,

and

SAE

30

}

joints

speedometer

drive

on

front wheel, front

and

rear

wheel

b~arings,

bear-

ings for chain sproczket

and

driving wheel with

cush-drive

r

spindle

for

High pressure

grease

foot-brake

pedal,

rear-

fork spindle, clutch-opera-

ting rod, kick-starter

spindle, twistgriPr steer-

ing-head

bearings.

..

Use no

Graphite

Additives in the Lubricating Oil

If this additive

is

present

in

too

large

a quantity

it

will

couse the oil

passages

in

the crankshaft to beconi'e

blocked, so

that

the oil supply to the big-end

bearing

is

interrupted. Serious

damage

to the

engine

will then

be inevitable.

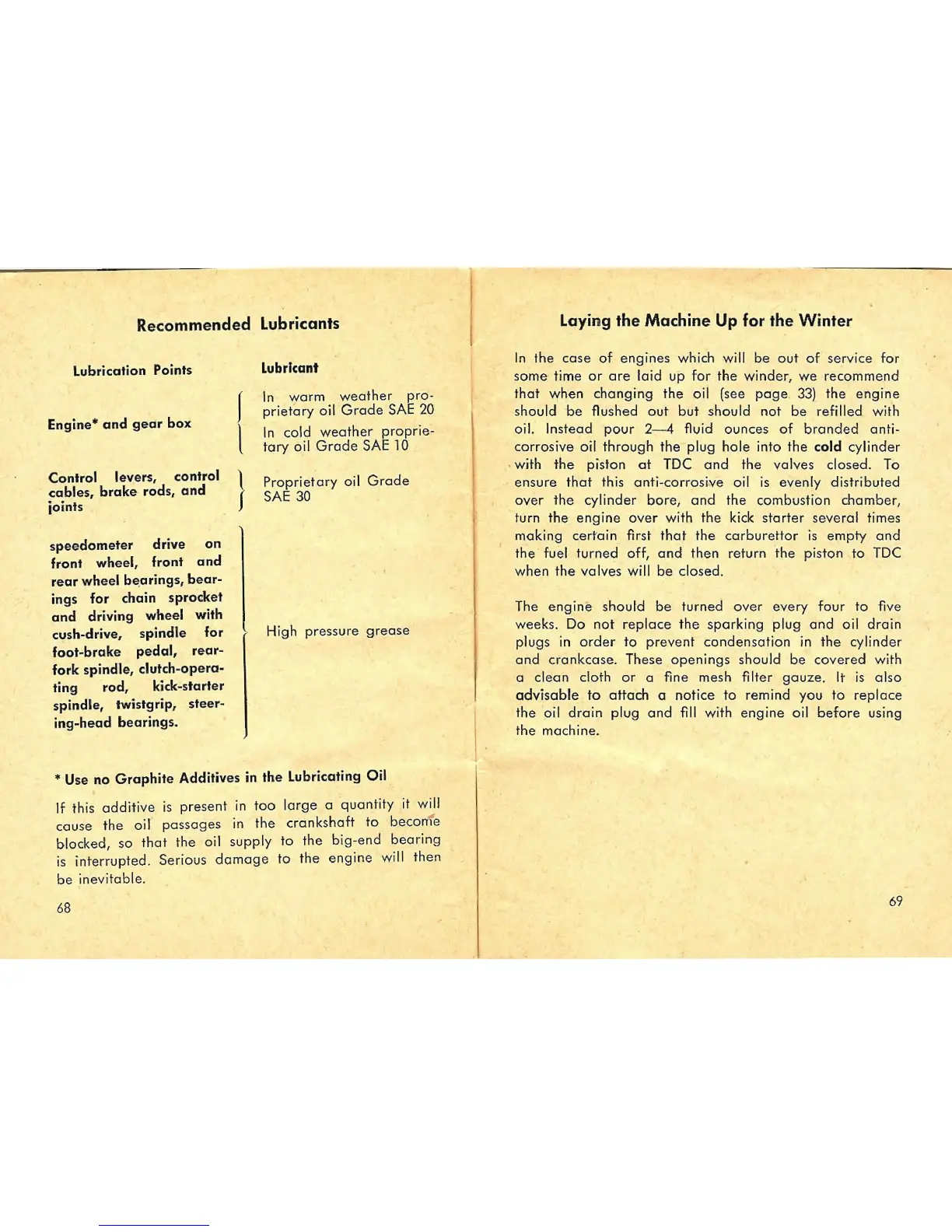

In

the

case

of

engines which will be

out

of

service for

some

time

or

are

laid up for the winder, we recommend

that

when changing the oil (see page.

33)

the engine

should be flushed

out

but should not be refilled with

oil. Instead

pour

2-4

fluid ounces

of

branded

anti-

corrosive oil

through

the plug hole into the cold cylinder

.with

the

piston

at

TDC

and

the valves closed.

To

ensure

that

this anti-corrosive oil

is

evenly distributed

over

the cylinder

bore,

and

the combustion

chamber

turn the

engine

over

with the

kick

starter

several

time~

making certain first

that

the

carburettor

is

empty

and

the fuel turned off,

and

then return the piston to

TDC

when

the

valves will

be

closed.

The

engine

should

be

turned

over

every four to five

weeks. Do not

replace

the sparking plug

and

oil drain

plugs

in

order

to prevent

condensation

in

the cylinder

and

crankcase. These

openings

should be covered with

a

clean

cloth

or

a fine mesh filter

gauze.

It

is

also

advisable

to

attach a notice to remind you to

replace

the oil

drain

plug

and

fill

with

engine

oil

before

using

the machine.

68

69

Loading...

Loading...