render them useless. Soft wheels give themselves up while

When grinding, only a small amount of material is removed,

and the wheel releases grains a little at a time, presenting new

cutting edges. This releasing activity helps to keep the tool from

heating up and gives a finer grinding result.

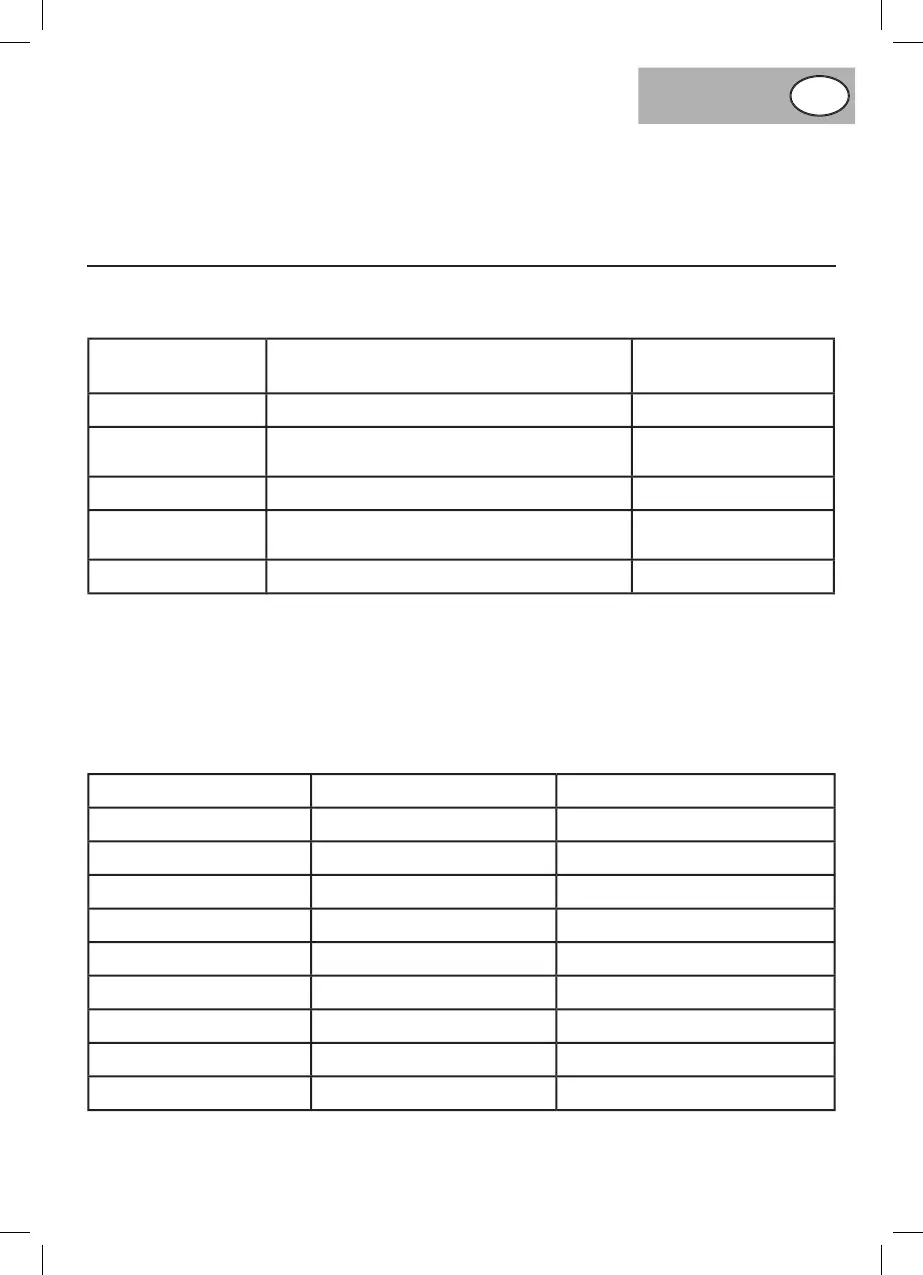

Table 2 shows wheel hardness and uses.

USES FOR DESIGNATED HARDNESS

Use these soft wheels to sharpen high-speed-steel tools,

such as router bits, drills, and tool bits.

Use these wheels for rough grinding on soft materials

This hard grade is used for dressing sticks to dress grinding

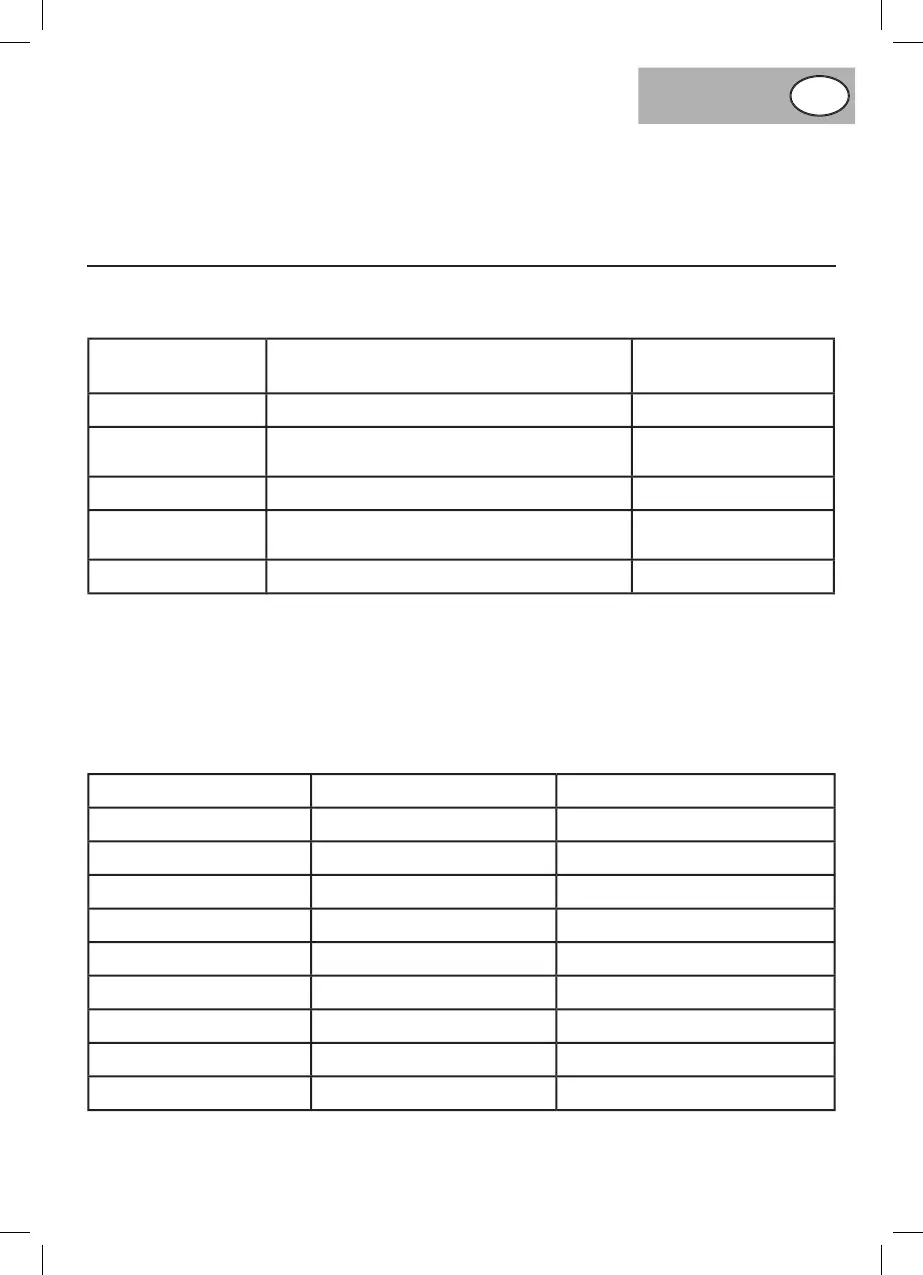

The following table 3 should help you to select the correct

grinding wheel for the job.

New bench grinders are supplied with grey wheels. All

other types of grinding wheel are available from your

Soft aluminium oxide (Pink or white)

Soft aluminium oxide (Pink or white)

Soft aluminium oxide (Pink or white)

High-speed steel carbide tipped

Hard steel (but not file hard)

Aluminium oxide (Pink or white)

Loading...

Loading...