IMPACT ECHO (IE)

www.olsoninstruments.com www.olsonengineering.com

Impact-Echo Scanner

The Impact-Echo rolling Scanner was first conceived by the second author of this paper and subsequently

researched and developed as a part of a US Bureau of Reclamation prestressed concrete cylinder pipe

integrity research project (6). This technique is based on the Impact-Echo method (5 and 7). In general,

the purpose of the Impact-Echo test is usually to either locate delaminations, honeycombing or cracks

parallel to the surface or to measure the thickness of concrete structures with typically one-sided access

for testing (pavements, floors, retaining walls, tunnel linings, buried pipes, etc.). To expedite the Impact-

Echo testing process, an Impact-Echo scanning device has been developed with a rolling transducer

assembly incorporating multiple sensors, attached underneath the test unit. When the test unit is rolled

across the testing surface, an opto-coupler on the central wheel keeps track of the distance. This unit is

calibrated to impact and record data at intervals of nominally 25 mm (1 inch). If the concrete surface is

smooth, a coupling agent between the rolling transducer and test specimen is not required. However, if

the concrete surface is somewhat rough, water can be used as a couplant to attempt to improve

displacement transducer contact conditions. The maximum frequency of excitation of the impactor in the

scanner used in research is 25 kHz. The impactor in scanner can be replaced for an impactor that

generates higher frequency.

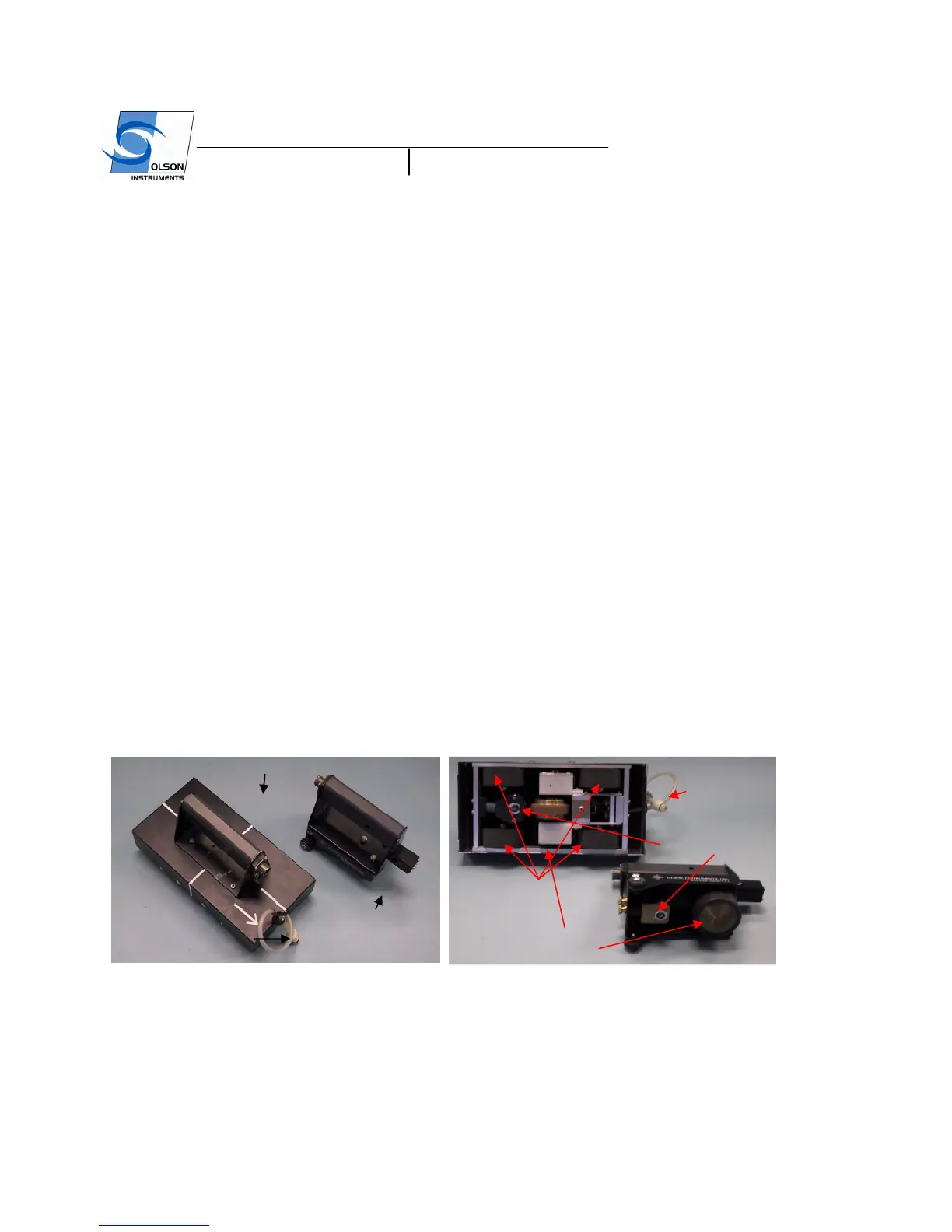

A comparison of the Impact-Echo Scanner and the point by point Impact-

Echo Scanner unit is shown in Figure 1. Typical scanning time for a line of 4 m (13 ft), approximately

160 test points, is 60 seconds. In an Impact-Echo scanning line, the resolution of the scanning is about 25

mm (1 inch) between IE test points. Data analysis and visualization was achieved using Impact-Echo

scanning software developed by the first author for this research project. Raw data in the frequency

domain were first digitally filtered using a Butterworth filter with a band-pass range of 2 kHz to 20 kHz.

Due to some rolling noise generated by the Impact-Echo Scanner, a band-stop filter was also used to

remove undesired rolling noise frequency energy. Automatic and manual picks of dominant frequency

were performed on each spectrum and an Impact-Echo thickness was calculated based on the selected

dominant frequency. A three-dimensional plot of the condition of the tested specimens was generated by

combining the calculated Impact-Echo thicknesses from each scanning line. The three-dimensional

results can be presented in either color or grayscale.

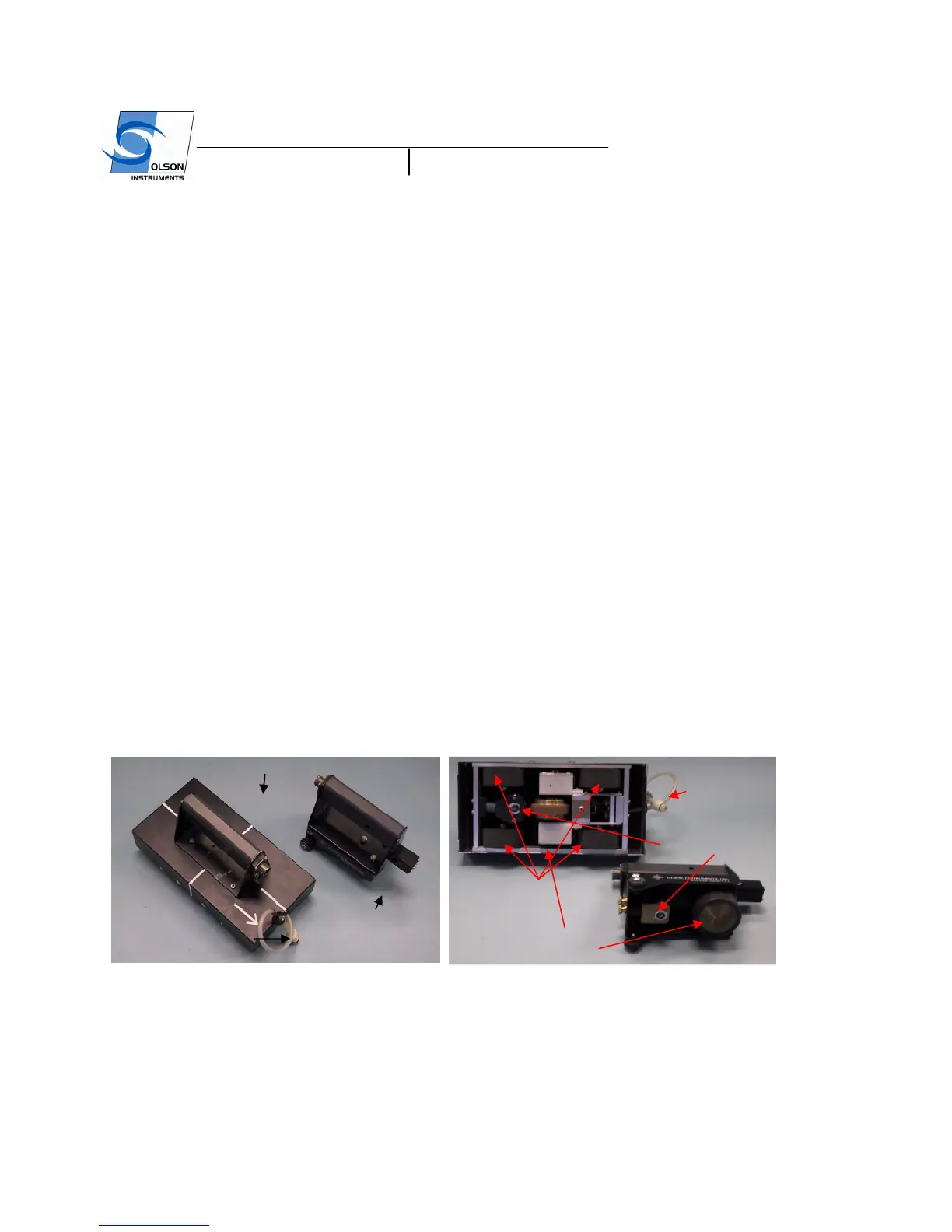

Figure 1 – Impact-Echo Scanner Unit and Point-by-Point Impact-Echo Unit

GENERAL DESCRIPTION OF THE SPECIMENS AND DEFECTS

Two mockup specimens were used in the study. The first specimen is a full scale pre-cast girder with

eight steel ducts inside. The second specimen is a mockup slab located at the BAM facility in Berlin,

Impact-Echo

Scanner

Point-by-point IE-1

tube to provide

water for

tube to provide

water for

Rolling transducer

Displacement transducer

automatic

impactors

wheels

Loading...

Loading...