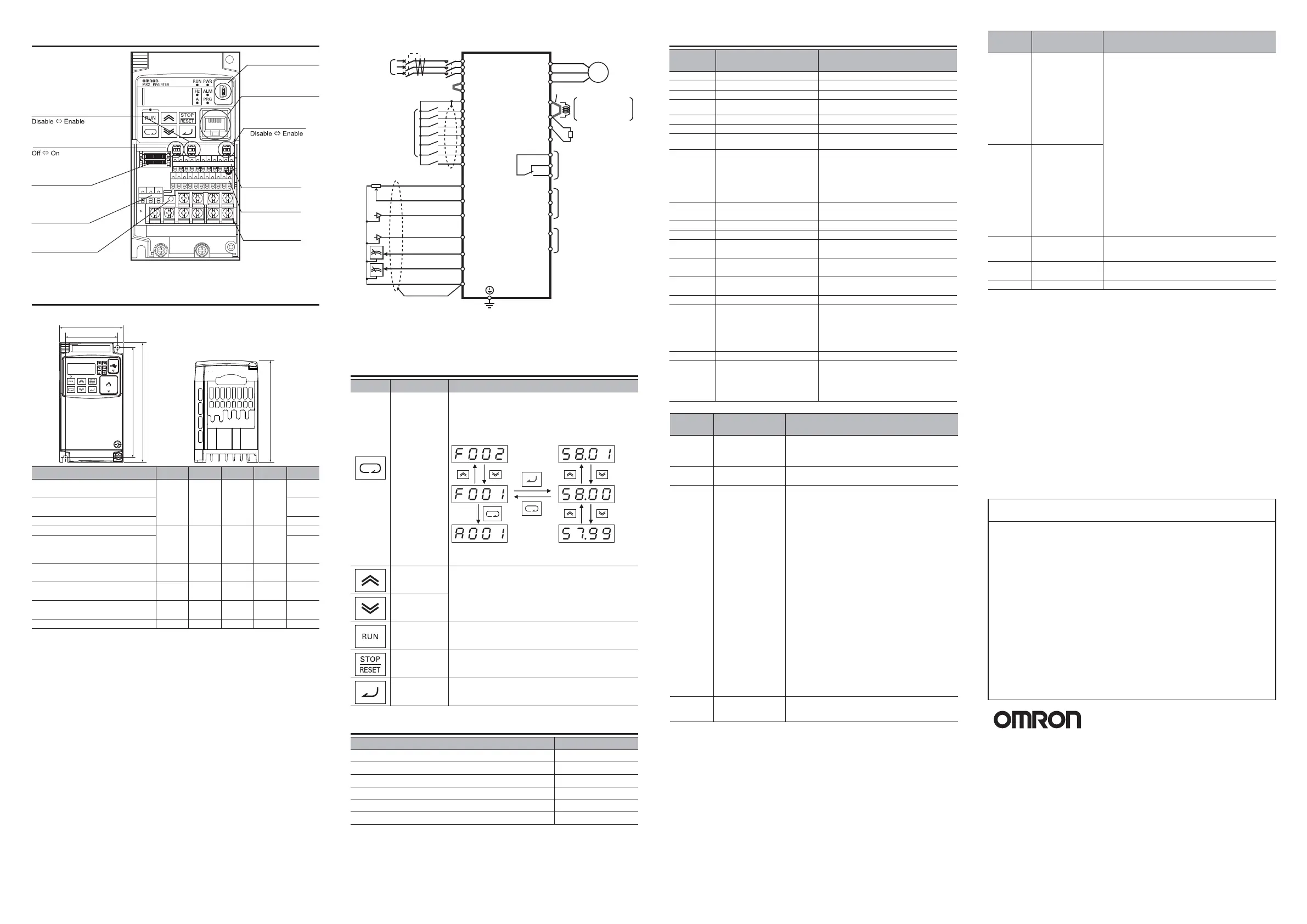

Installation and Wiring

Dimensions

A2150-V1 175336

AB007-V1, AB015-V1, AB022-V1

A2015-V1, A2022-V1, A4007-V1

A4015-V1, A4022-V1, A4030-V1

350192220

[mm]

A2110-V1

A4110-V1, A4150-V1

180 160 296 284 175

A2055-V1, A2075-V1

A4055-V1, A4075-V1

140 122 260 248 155

A2037-V1

A4040-V1

140 128 128 118 170.5

A4004-V1

108 96 128 118

170.5

143.5

A2007-V1

AB004-V1

A2004-V1

AB001-V1, AB002-V1

A2001-V1, A2002-V1

3G3MX2-

WW1H H1 D

68 56 128 118

145.5

122.5

109

W1

W

H1

H

D

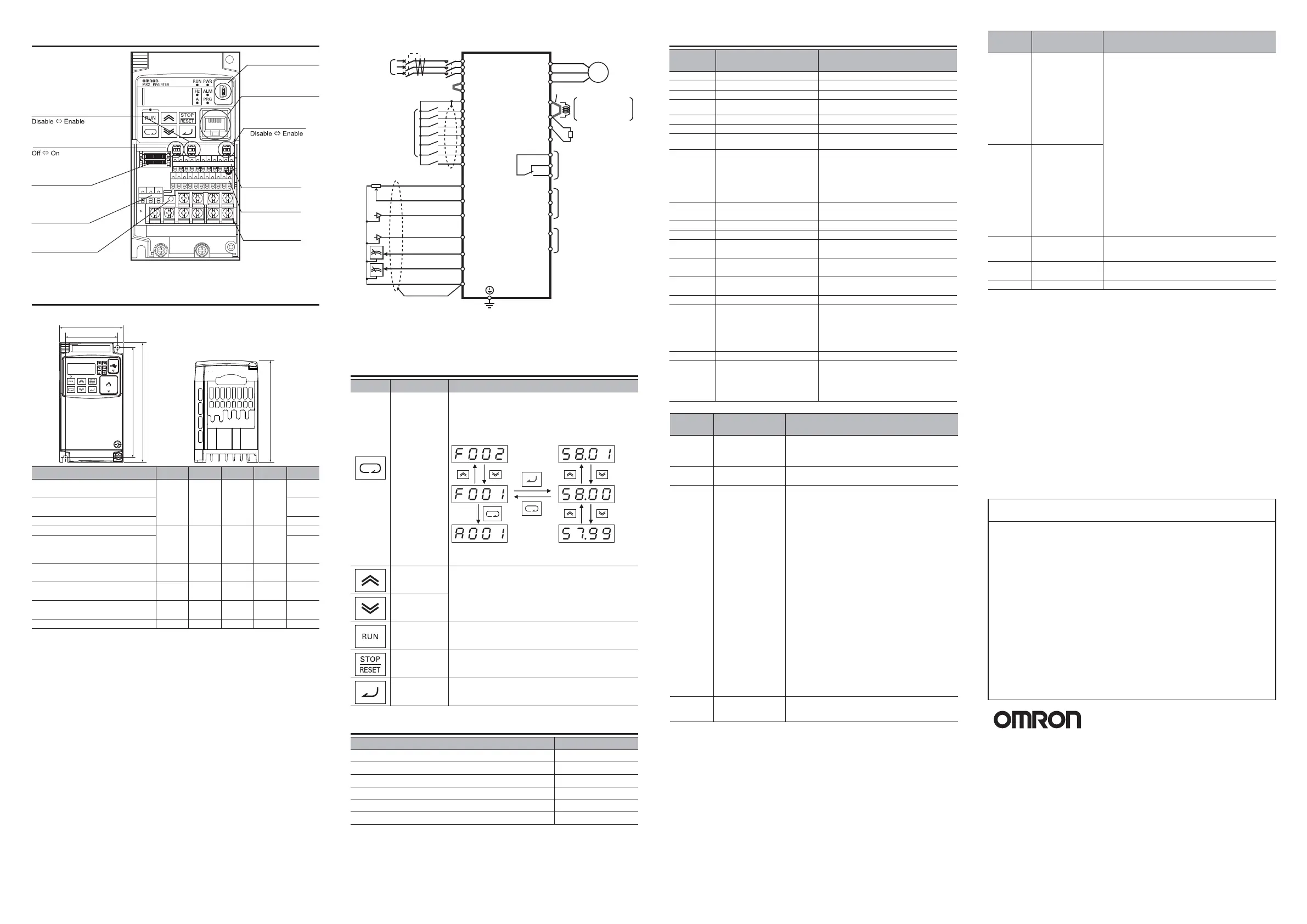

Standard Connection Diagram

*1. Connect a single-phase 200V AC input to terminals L1 and N.

*2. Factory default settings for relay output are NC contact for MA and NO

contact for MB.

Single-phase/

3-phase

power supply

Short-circuit bar

Short-circuit bar

Motor

ELB

MC

R/L1(L1) *1

S/L2

T/L3(N) *1

MC

S7/EB

S5/TH

S4/GS2

S3/GS1

S2

S1

FS

FV

FI

RP

AM

MP

RS-

RS+

PC

P1/EDM

P2

MB

MA

N/-

SC

S6

P24

DCL

PSC

SC

Multi-function input

(7 contacts)

Multi-function output

(2 terminals)

Multi-function contact output *2

Braking resistor

WRN

10V DC power supply

(10 mA max.)

Analog voltage input

0 to 10 V (10 bits)

Analog voltage output

0 to 10 V (10 bits)

Class D (200-V class)

Class C (400-V class)

Analog current input

4 to 20 mA (10 bits)

Pulse train input

5 to 24 V DC

(32 kHz max.)

Pulse train output

0 to 10 V (32 kHz max.

)

Serial communications

port

(RS485/Modbus)

RB

P/+2

+1

W/T3

V/T2

U/T1

M

3~

To connect the DC

reactor (DCL), remove

the short-circuit bar.

In case two or more

inverters are connected

to common I/O wiring,

special care to be taken

to avoid closed loop

circuit. Please refer to

user’s manual.

Keys

Name Description

Mode key

Increment

key

Decrement

key

RUN key

STOP/RESET

key

Enter key

x

Moves to the next function mode when the parameter

number is displayed.

x

Cancels the set data in the process of change and

displays the parameter number when the parameter

data is displayed.

Status transition

Changes the set values, parameters and Commands

Starts the operation. Forward / Reverse rotation

depends on the ‘F004’ setting.

Stops the operation. Functions as the Reset key

if an error occurs.

x

Switches the display from the parameter number to

set data.

x

Enters and stores the set data.

* Press and hold the Mode key for 3 seconds or more

to jump to the d 001 data display.

Related Manuals

W453-E1

I580-E1

I563-E1

I574-E1

I582-E1

I581-E1

Name Catalog No.

CX-Drive Operation Manual

DriveProgramming User’s Manual

Regenerative Braking Unit 3G3AX-RBU User’s Manual

EtherCAT Communication Unit User’s Manual

CompoNet Communication Unit User’s Manual

DeviceNet Communication Unit User’s Manual

Parameter

No.

Function name Monitor or data range

d001 Output frequency monitor 0.00 to 400.0 [Hz]

d002 Output current monitor 0.0 to 655.3 [A]

d003 Run direction monitor F: forward /o: stop /r: reverse

F001 Output frequency setting/ monitor Starting Frequency(b082) to max. Frequency

(A004) [Hz]

F002 1st Acceleration time1 0.00 to 3600. [s]

F003 1st Deceleration time1 0.00 to 3600. [s]

F004 1st Operator run direction

selection

00: forward

01: reverse

A001 1st Frequency reference

selection

00: Digital Operator(volume)

(Enable when 3G3AX-OP01 is used) /

01: Terminal /02: Digital Operator(F001) /

03: Modbus communication /04: Option /

06: Pusle train frequency /

07: DriveProgramming /

10: Frequency operation result

A002

1st Run command selection 01: Terminal /02: Digital Operator /

03: Modbus communication /04: Option

A003 1st Base frequency 30.0 to max. frequency(A004) [Hz]

A004 1st Maximum frequency Base frequency(A003) to 400.0 [Hz]

A019 Multi-step speed selection 00: Binary(16-step selection with 4 terminals)

01: bit (8-step selection with 7 terminals)

A020 1st Multi-step speed reference 0 0.00, /Starting Frequency(b082) to Max.

Frequency(A004) [Hz]

A021 to A035

Multi-step speed reference 1 to 15

0.00, /Starting Frequency(b082) to Max.

Frequency(A004) [Hz]

b012 1st Electronic Thermal Level 20% to 100% of the inverter rated current [A]

b037 Display Selection 00: Complete display

01: Individual display of functions

02: User setting + b037

03: Data comparison display

04: Basic display

05: Monitor display only

b082 Starting Frequency 0.01 to 9.99 [Hz]

b084 Initialization selection 00: Disabling /01: Clearing the trip history /

02: Initializing the data /03: Clearing the trip

history and initializing the data /04: Clear

fault monitor + initialize data + Clear

DriveProgramming

Parameter

No.

Function name Monitor or data range

C021

to C022

Multi-function

output P1, P2

selection

00:RUN(during RUN)) /01:FA1(constant speed reached) /

02:FA2(set frequency min. reached) /03:OL(overload

warning) /04:OD(PID excessive deviation) /05:AL(alarm

output) /06:FA3(disconnection defected) /07:OTQ(over

torque) /09:UV(signal during undervoltage) /10:TRQ(torque

limit) /11:RNT(RUN time over) /12:ONT(power on time

over) /13:THM(thermal warning) /19:BRK(brake release) /

20:BER(brake error) /21:ZS(0Hz) /22:DSE(excessive speed

deviation) /23:POK(position ready) /24:FA4(set frequency

exceeded 2) /25:FA5(set frequency only 2) /26:OL2

(overload warning 2) /27:FVdc(analog FV disconnection

detection) /28:FIDc(analog FI disconnection detection) /

31:FBV(PID FB status output) /32:NDc(network error) /

33-35:LOG1-3(logic operation output1-3) /39:WAC

(capacitor life warning) /40:WAF(cooling fan life warning) /

41:FR(starting contact signal) /42:OHF(fin overheat

warning) /43:LOC(low current signal) /44-46:MO1 to 3

(General-purpose Output 1 to 3) /50:IRDY(operation ready) /

51:FWR(during forward operation) /52:RVR(during reverse

operation) /53:MJA(fatal fault signal) /54:WCFV(window

comparator FV) /55:WCFI(window comparator FI) /

58:FREF(Frequency Command Source) /59:REF

(Run Command Source) /60:SETM(2nd Motor Selection) /

62:EDM(STO(Safe Torque Off) Performance Monitor(C021

only)) /63:OPO(Option) /no:NO(not assigned)

C026 Multi-function Relay

output (MA, MB)

function selection

C031

to C032,

C036

Multi-function Relay

output operation

selection

00:NO contact at P1, P2, MA, NC contact at MB

01:NC contact at P1, P2, MA, NO contact at MB

H003 1st Motor Capacity 0.1 / 0.2 / 0.4 / 0.55 / 0.75 / 1.1 / 1.5 / 2.2 / 3.0 / 3.7 / 4.0 /

5.5 / 7.5 / 11.0 / 15.0 / 18.5 [kW]

H004 1st Motor pole number 2 to 48 [pole] (Only even poles can be set.)

NT328XC

Parameter List

2272253-5D

Names of Parts

Modbus Communication

Termination resistor selector switch

Safety function selector switch

USB connector (mini-B)

Connector for

option

Multi-function contact

terminal block

CHARGE indicator

Connector for

Digital Operator (RJ45)

EDM function

selector switch

Control circuit

terminal block A

Control circuit

terminal block B

Main circuit

terminal block

Parameter

No.

Function name Monitor or data range

b180 Initialization Execution 00: Function is disabled

01: Execute initialization

C001

to C007

Multi-function

input S1 to S7

selection

00:FW(forward) /01:RV(reverse) /02-05:CF1-4(multi-step

speed1-4) /06:JG(jogging) /07:DB(external DC injection

braking) /08:SET(2nd control) /09:2CH(2-step acceleration

/deceleration) /11:FRS(free run stop) /12:EXT(external trip)

/13:USP(USP function) /14:CS(commercial switch) /15:SFT

(soft lock) /16:FV/FI(analog input switch) /18:RS(reset) /

19:TH(PTC thermistor Thermal Protection(C005 only)) /

20:STA(3-wire start) /21:STP(3-wire stop) /22:F/R(3-wire

forward/reverse) /23:PID(PID enable/disable) /24:PIDC

(PID integral/reset) /27:UP(UP/DWN function accelerated) /

28:DWN(UP/DWN function decelerated) /29:UDC(UP/DWN

function data clear) /31:OPE(forward operator) /32-38:SF1-

7(multi-step speed bit1-7) /39:OLR(overload limit switching)

/40:TL(torque limit enabled) /41:TRQ1(torque limit switching

1) /42:TRQ2(torque limit switching 2) /44:BOK(brake

confirmation) /46:LAC(LAD cancel) /47:PCLR(position

deviation clear) /50:ADD(frequency addition) /51:F-TM

(forced terminal block) /52:ATR(torque command input

permission) /53:KHC(integrated power clear) /56-62:MI1 to

7(General-purpose input 1 to 7) /65:AHD(analog command

held) /66-68:CP1-3(position command selection1-3) /

69:ORL(zero return limit signal) /70:ORG(zero return startup

signal) /73:SPD(speed/position switching) /77:GS1(GS1

input(C003 only)) /78:GS2(GS2 input(C004 only)) /81:485

(Start co-inverter communication) /82:PRG

(DriveProgramming start) /83:HLD(Retain output frequency)

/84:ROK(Permission of Run command) /85:EB(Rotation

direction detection(C007 only)) /86:DISP(Display limitation) /

91:PSET(Preset position) /no:NO(not assigned)

C011

to C017

Multi-function

input S1 to S7

operation selection

00: NO

01: NC

b094 Initialization Target

Setting

00: All data

01:

All data other than terminals/communications

02: U*** registration function only

03: Other than U*** registration function

SUITABILITY FOR USE

Omron Companies shall not be responsible for conformity

with any standards, codes or regulations which apply to

the combination of the product in the buyer’s application

or use of the product.

At buyer’s request, Omron will provide applicable third party certification

documents identifying ratings and limitations of use which apply to the product.

This information by itself is not sufficient for a complete determination of the

suitability of the product in combination with the end product, machine, system,

or other application or use. Buyer shall be solely responsible for determining

appropriateness of the particular product with respect to Buyer’s application,

product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS

RISK TO LIFE OR PROPERTY OR IN LARGE QUANTITIES WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY

RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD

Hoofddorp

The Netherlands

Tel: (31)2356-81-300

Fax: (31)2356-81-388

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08

(Lobby 2), Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011

Fax: (65) 6835-2711

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900

Fax: (1) 847-843-7787

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

Pu Dong New Area, Shanghai,

200120, China

Tel: (86) 21-5037-2222

Fax: (86) 21-5037-2200

OMRON Corporation

Industrial Automation Company

moc.normo.ai.www :tcatnoC

Tokyo, JAPAN

Note: Specifications subject to change without notice.

Loading...

Loading...