6.

Tighten

the cap screws to the specified torque.

7.

Crank the engine over by hand to see that the

bearings are free.

8.

Install

the oil

base

with

a new gasket.

9.

Install

the

cylinder

head using an even

bolt

tightening

sequence

and specified torque.

10.

Replace oil.

CAMSHAFT

The

camshaft is a one-piece machine casting,

driven

through

gears

by the crankshaft. It rides on sleeve

bearings pressed

into

the crankcase.

In

addition

to

providing

a

means

of opening and closing

the valves, the camshaft

operates

the

injection

pump

and

fuel

transfer pump.

Removal:

1.

Remove the rocker arms and push rods

from

the

valve

chambers.

2.

Remove the

injection

pump and

fuel

transfer pump

from

the engine.

3. Remove the crankshaft

gear

retaining washer by

removing

the

lock

ring

on the crankshaft.

4.

Lay the engine on side to

avoid

dropping tappets

and

remove the camshaft assembly as a group. If

necessary,

pry it out

with

a screwdriver between

the camshaft

gear

and crankcase..

5. Remove the valve tappets. These can be removed

only

from

the camshaft end of the push rod holes.

Repair: If a lobe has become

slightly

scored,

dress

it

smooth

with

a

fine

stone. If the camshaft is badly

worn

or

scored, replace it.

After

installing

a new camshaft,

retime

the

injection

pump to the engine.

Camshaft Gear: This

gear

is

&

pressed fit on the cam-

shaft and drives it at 1/2 the crankshaft

speed.

To

remove the goar, use a

hollcw

tool

or pipe that

will

fit

inside the

gear

bore and over the center pin.

Press

the camshaft out of the

'

gear

bore. Be careful not to

damage the cf.'nter pin.

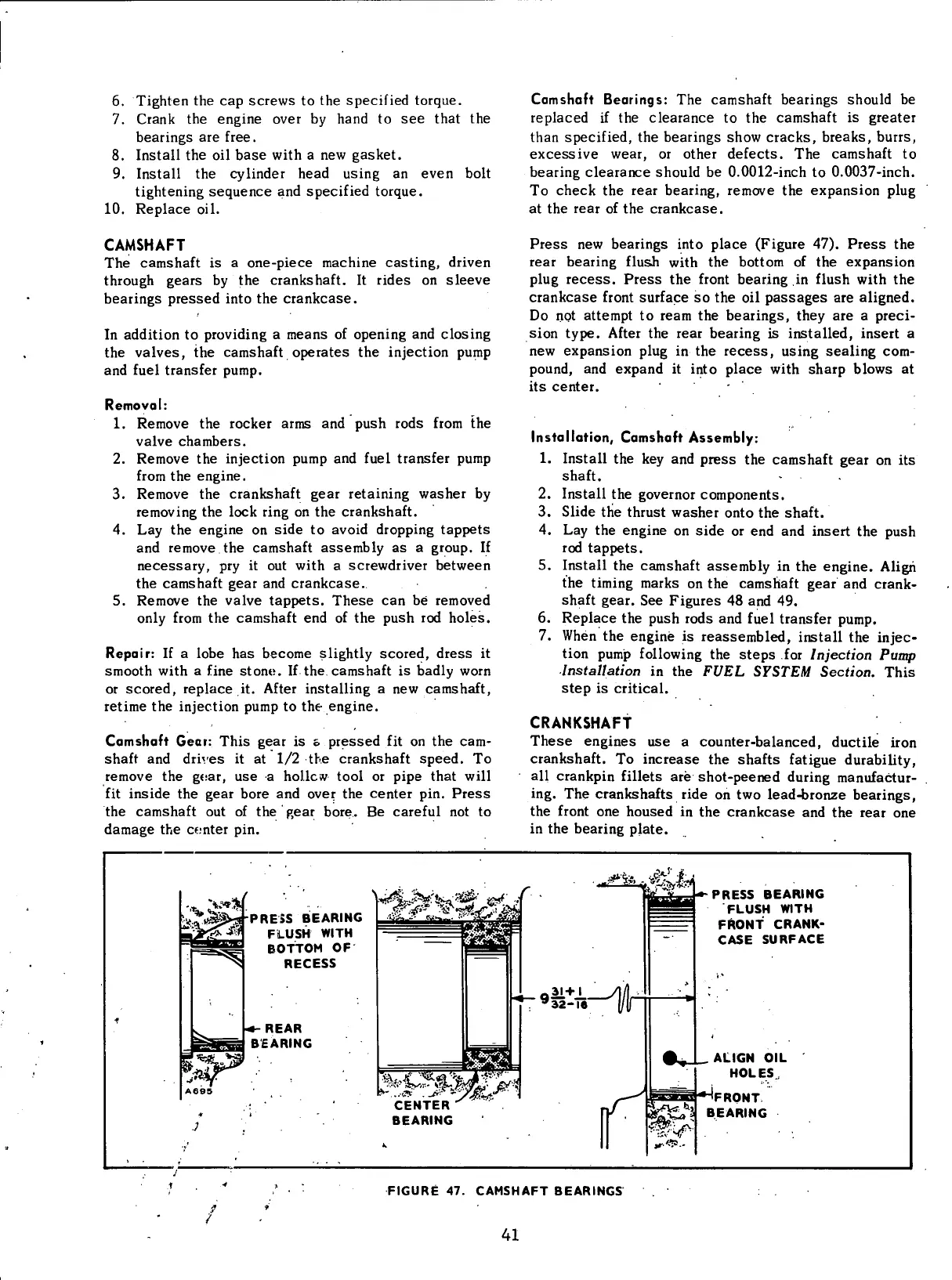

Camshaft Bearings: The camshaft bearings should be

replaced if the clearance to the camshaft is greater

than

specified, the bearings show cracks, breaks, burrs,

excessive wear, or other defects. The camshaft to

bearing

clearance should be 0.0012-inch to 0.0037-inch.

To

check the rear bearing, remove the expansion

plug

at the rear of the crankcase.

Press

new bearings

into

place (Figure 47).

Press

the

rear bearing

flush

with

the bottom of the expansion

plug

recess.

Press

the

front

bearing in

flush

with

the

crankcase

front

surface so the oil

passages

are aligned.

Do

not attempt to ream the bearings, they are a

preci-

sion

type.

After

the rear bearing is installed, insert a

new

expansion

plug

in the

recess,

using sealing com-

pound,

and expand it

into

place

with

sharp blows at

its

center.

Installation,

Camshaft

Assembly:

1.

Install

the key and

press

the camshaft

gear

on its

shaft.

2.

Install

the governor components.

3. Slide the thrust washer onto the shaft.

4.

Lay the engine on side or end and insert the push

rod

tappets.

5.

Install

the camshaft assembly in the engine.

Align

the

timing

marks on the camshaft

gear

and crank-

shaft

gear.

See Figures 48 and 49.

6. Replace the push rods and

fuel

transfer pump.

7.

When the engine is reassembled,

install

the

injec-

tion

pump

following

the

steps

for

Injection

Pump

•Installation

in the

FUEL

SYSTEM

Section. This

step

is

critical.

CRANKSHAFt

These engines use a counter-balanced, ductile

iron

crankshaft. To increase the shafts fatigue

durability,

all

crankpin

fillets

are shot-peened

during

manufactur-

ing.

The crankshafts ride on two lead-bronze bearings,

the

front

one housed in the crankcase and the rear one

in

the bearing plate.

PRESS

BEARING

FLUSH

WITH

BOTTOM

OF

RECESS

[4-

REAR

BEARING

•-PRESS

BEARING

FLUSH

WITH

FRONT

CRANK-

CASE

SURFACE

CENTER

BEARING

ALIGN

OIL

HOLES.,

FIGURE

47.

CAMSHAFT

BEARINGS

41

Loading...

Loading...