seating on the cylinder

wall.

Fit

each

ring

to the cylinder

wall

at the bottom of its' travel, using the piston to

square

the

ring

in the bore. Check the gap

with

a feeler

gage.

It

should

be .010" to .020". If the gap is too small,

file

the

butt

ends

of the rings. Do not use rings that need a lot

of

filing,

they

will

not

seat

right

on the cylinder

wall.

If an

oversize piston is used, use the correct oversize rings.

CONNECTING

RODS

Clean the connecting rod and check for defects. Check the

connecting rod bushings for proper

clearance

with

the piston

pin.

Clearance should be .0002" to .0007".

If

the bushings are excessively

worn,

press

them out and

install

one new bushing

from

each

side of the bushing bore.

Press

the new bushings

only

until

flush

with

the

sides

of

the rod to leave 1/16" to 7/64" oil groove in the center

(Fig.

12-2).

CONNECTING

ROD

BEARINGS

Inspect the connecting rod bearings for burrs, breaks, pits

and wear. Measure the

clearance

between bearings and the

crankshaft

journal.

The

clearance

should be

.001"

to .003".

If

necessary,

replace

with

new standard or oversize pre-

cision

bearings.

For

information

about the crankpin journals, see Engine

Disassembly Section.

ASSEMBLY

AND

INSTALLATION

1.

Install

the connecting rod on the piston

with

the pin

and retaining rings. If new bushings were installed,

check to see that the

ends

are

flush

with

the connect-

ing

rod to provide for the

oil

recess

in the center.

.

2.

Install

the rings on the piston.- Tapered rings

will

be

marked top or

identified

in

some

pther manner.

Place

this

mark toward the closed end of the piston.

Space

the

ring

gaps

1/4 gap of the way around the piston

from

one another. No gap should be in

line

with

the piston

pin.

Oil

the rings and piston.

3. Position a bearing

half

in the connecting rod. Be

sure

there is no

dirt

under the bearing. This could

cause

high

spots

and early bearing

failure.

4.

Oil the cylinder

wall.

Install

the piston in the cylinder

using

a suitable installer. The assembly should be in-

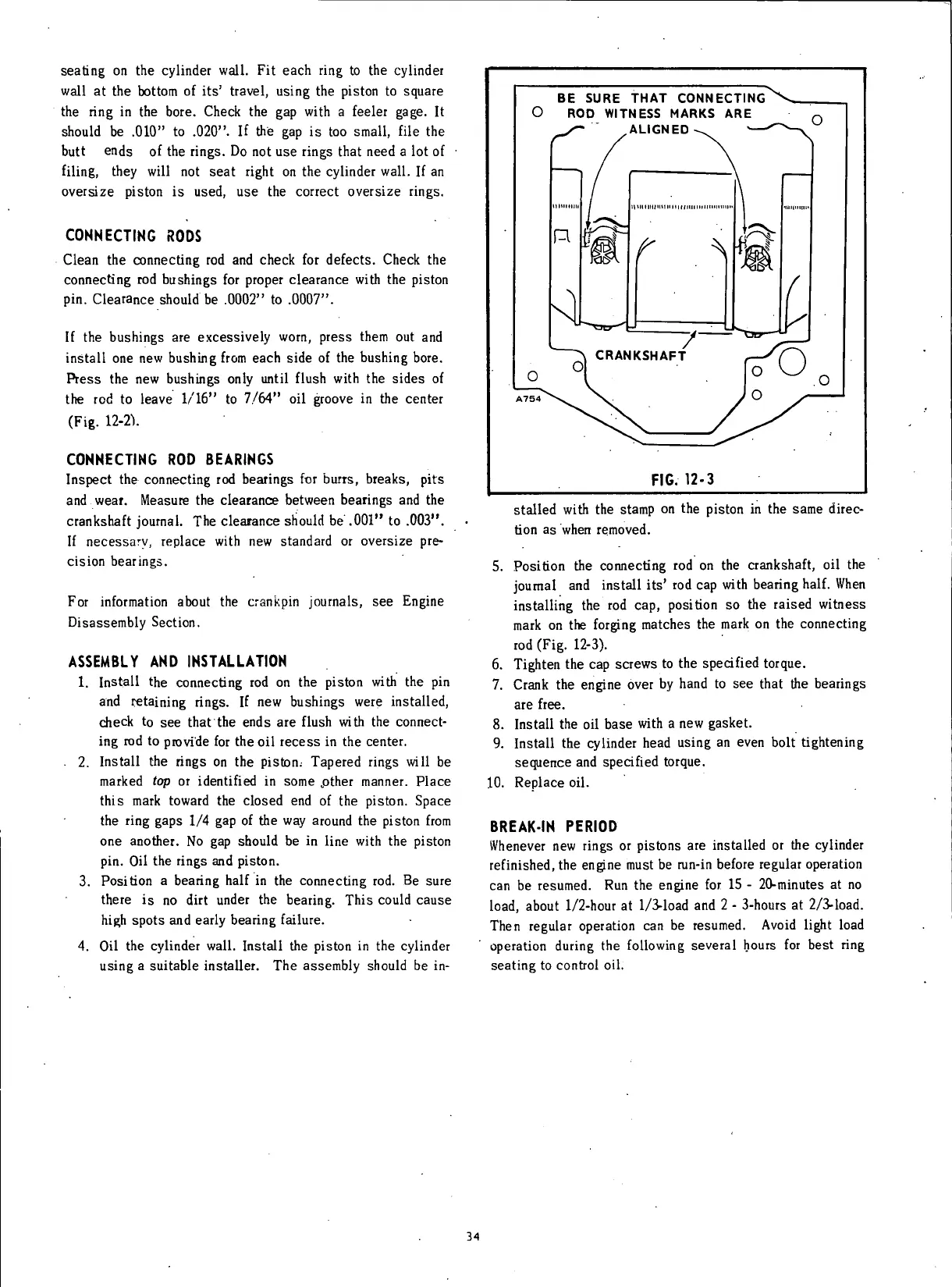

BE

SURE

THAT

CONNECTING

O

ROD

WITNESS

MARKS

ARE

ALIGNED

nmillU'ltlllllHimillil

y-

o

CRANKSHAFT

FIG.

12-3

stalled

with

the stamp on the piston in the

same

direc-

tion

as when removed.

5. Position the connecting rod on the crankshaft, oil the

joumal

and

install

its' rod cap

with

bearing

half.

When

installing

the rod cap, position so the raised witness

mark

on the

forging

matches

the mark on the connecting

rod

(Fig.

12-3).

6. Tighten the cap screws to the specified torque.

7. Crank the engine over by hand to see that the bearings

are free.

8.

Install

the oil

base

with

a new

gasket.

9.

Install

the cylinder head using an even

bolt

tightening

sequence

and specified torque.

10.

Replace

oil.

BREAK-IN

PERIOD

Whenever new rings or pistons are installed or the cylinder

refinished,

the engine must be

run-in

before regular operation

can be resumed. Run the engine for 15 - 20-minutes at no

load,

about

1/2-hour

at 1/3-load and 2 - 3-hours at 2/3-load.

Then

regular operation can be resumed.

Avoid

light

load

operation during the

following

several hours for

best

ring

seating to control oil.

34

Loading...

Loading...