FRONT END ALIGNMENT

3C-23

ing geometry, the following checks and inspections

must be made to insure correctness of alignment

equipment readings and alignment adjustments.

1. The front tires should have approximately the

same wear and all tires must be inflated to specified

pressures (see Wheel and Tire Specifications

-

Sec-

tion 3G).

2. Check front wheel bearings for looseness and ad-

just if necessary (see Front Suspension Adjustments

-

Section 3A).

3. Check for run-out of wheels and tires, (see Section

3G).

4. Check wheels and tires for balance and correct if

out-of-balance (See Section 3G).

5. Check for looseness at ball joints and tie

rdd ends;

if found excessive, it must be corxcted before align-

ment readings will have any value.

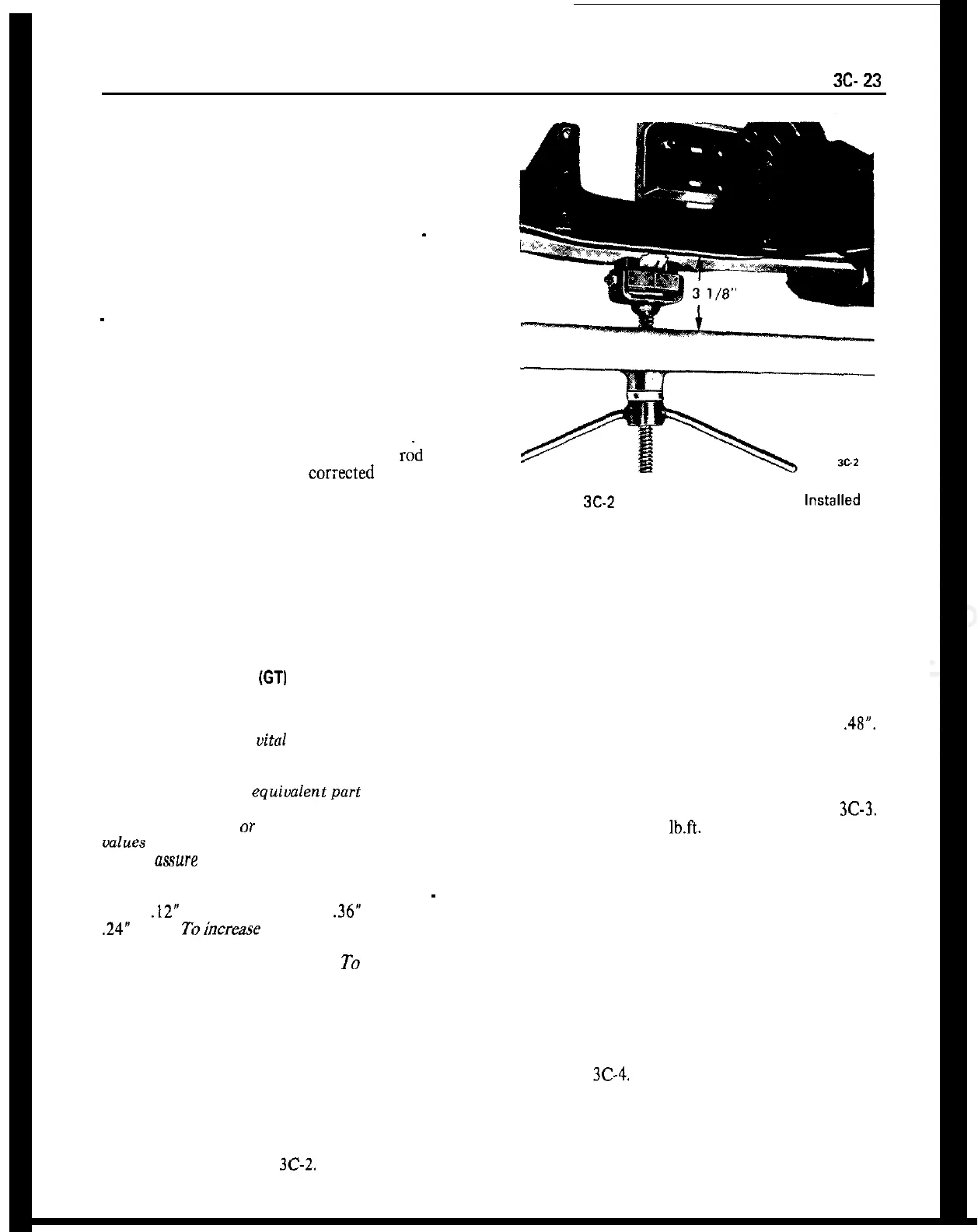

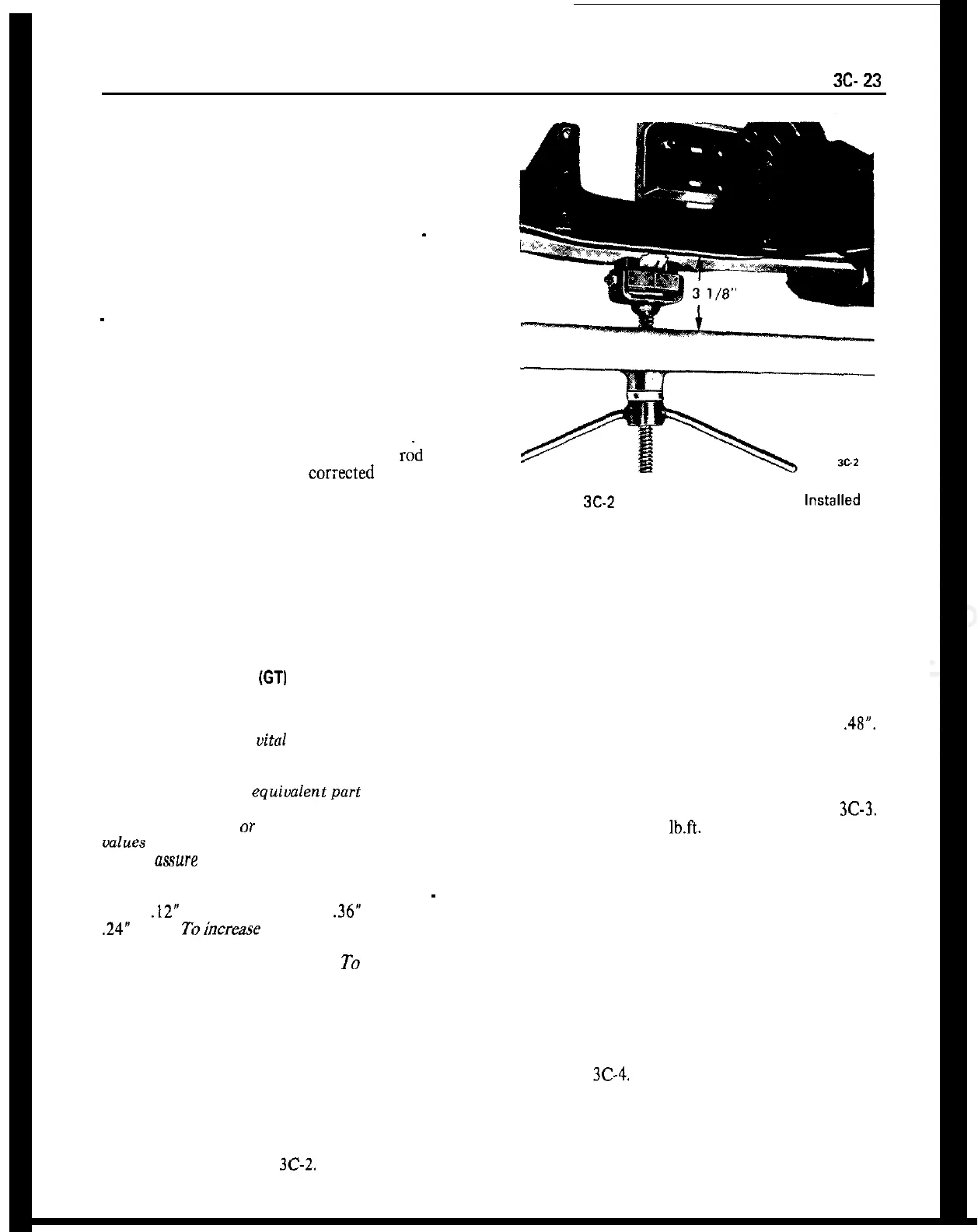

Figure

SC-Z

Spring Compressor J-2 1689 Installed

6. Check shock absorber action and correct if neces-

sary. Consideration must be given the optional

equipment on the car, undercoating, dirt, etc.

7. It is advisable to check the condition and accuracy

of any equipment being used to check front end

alignment and to make certain that instructions of

the manufacturer are thoroughly understood.

ADJUSTING CASTER

(GT)

4. Remove upper control arm shaft,

5. Remove upper control arm from shock absorber

support, being careful not to lose toothed washers.

6. Adjust caster by installing selective toothed wash-

ers on both sides of control arm shaft, between con-

trol arm and shock absorber support. Never use

CAUTION: Front suspension fasteners are impor-

more than one washer at any one location. The total

tant attaching parts in that they could

affect thickness, front and rear washer, must equal

.48”.

the performance of

uital

components and sys-

tems, and/or could result in major repair expense.

There are only two possible caster changes that can

be made.

They must be replaced with one of the same

part

number or with an

equiualentpart

ifreplacement

becomes necessary. Do not use a replacement part

Of lesser quality

or

substitute design. Torque

values

must be used as specified during reassem-

bly to

mure

proper retention of these parts.

7. Using a drift to align holes, replace control arm

shaft in the direction as shown in Figure

3C-3.

Torque hex nut to 33

lb.ft.

Make certain that crown

of both plate washers shows outward.

To change caster, three washers are available

-

one

with a

.12”

thickness, one that is

.36”

thick, and one

.24”

thick. Toincrease caster place one of the thin

washers at the front of the control arm shaft and one

of the thick washers at the rear.

To decrease caster

place one thick washer at the front of the control

arm shaft and one thin washer at the rear.

1. Position jack below front suspension cross mem-

ber and raise front end of car.

8. Remove spring compressor, and install front

wheel and torque wheel nuts to 72 ft. Ibs.

9. Recheck caster.

ADJUSTING CASTER (OPEL 1900. MANTA)

2. Place jack stands below front frame side members

and remove front wheel on side which caster is to be

adjusted.

1. Jack up vehicle and remove front wheel on the side

on which caster is to be adjusted.

3. Install front spring compressor J-21689 and com-

press spring. See Figure

3C-2.

2. Support vehicle below both lower control arms.

See Figure

3C-4.

3. Unscrew hex nut from upper control arm shaft

and pull out shaft.

4. Adjust caster by replacing washers (A) (front) and

Loading...

Loading...