WHEELS AND TIRES 3G- 57

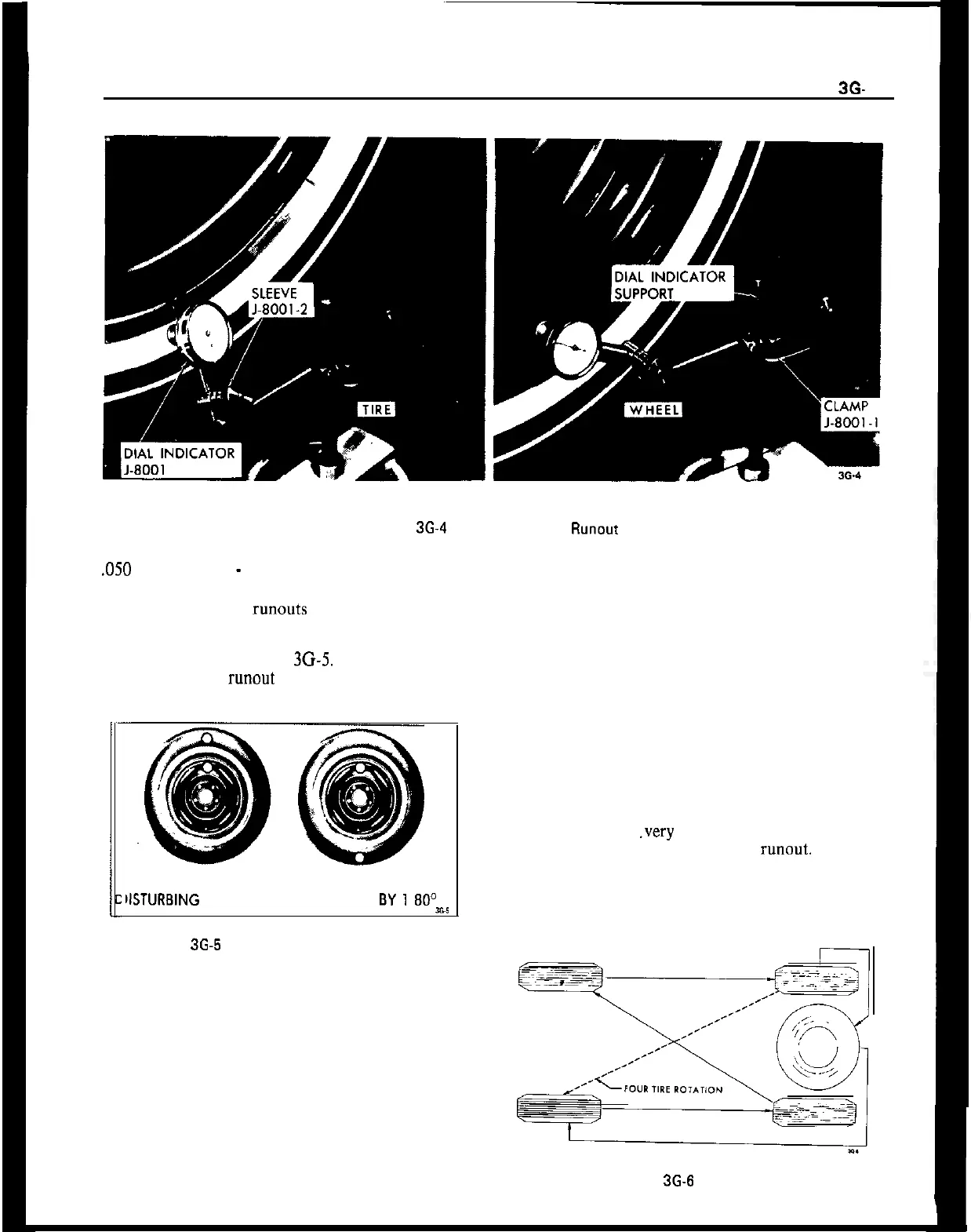

Figure

3G-4

Checking Lateral

Runout

,050

inch Lateral

-

Tire/Wheel Assembly

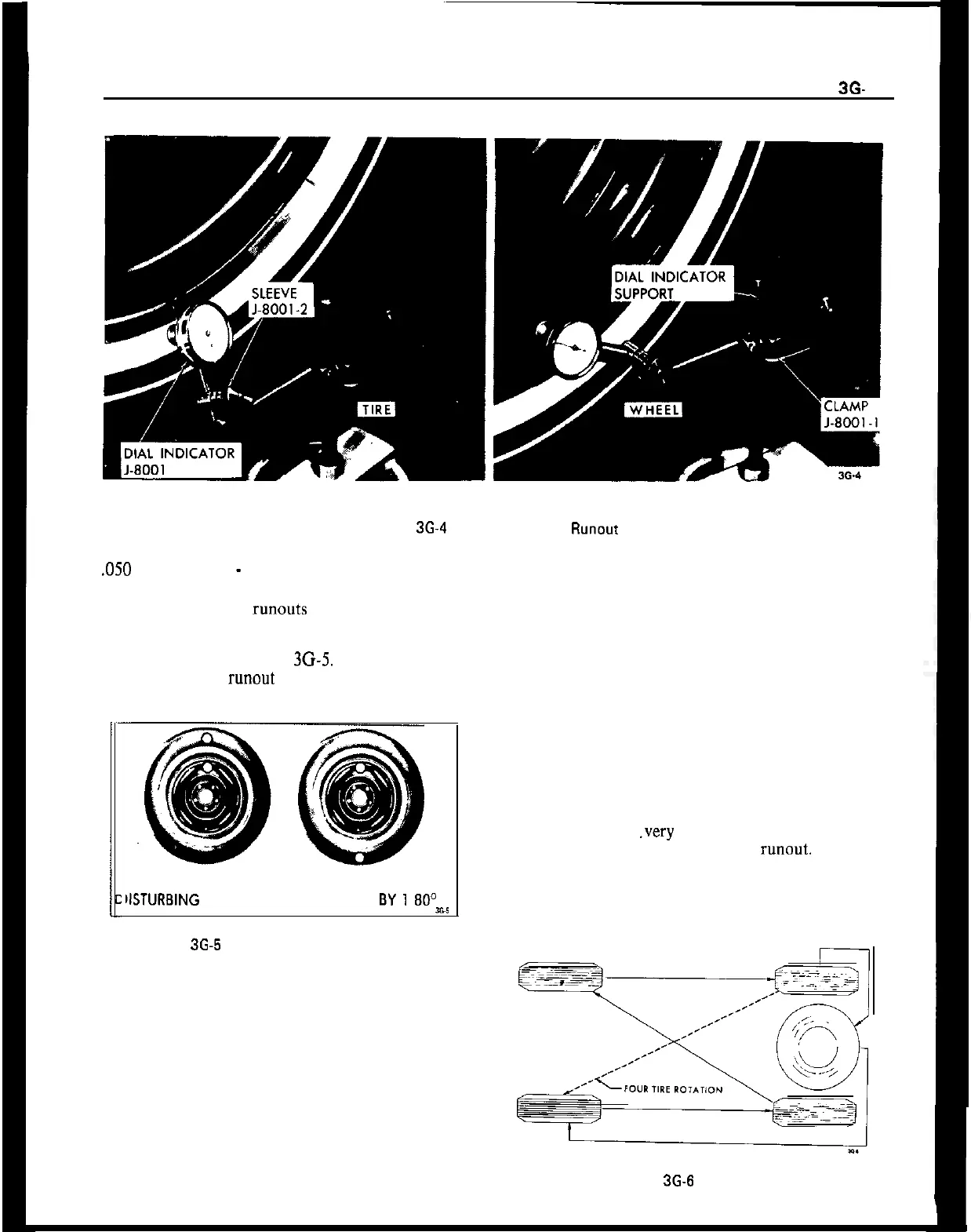

If the tire and wheel runouts are beyond any of the

maximum totals above, the tire should be reposi-

tioned 180 degrees opposite its original location on

the wheel. Refer to Figure

3G-5.

This will, in most

cases, reduce the runout and vibration to a satisfac-

tory level.

ASSEMBLY CAUSING REPOSITION TIRE/WHEEL

IISTURBING

VIBRATIONS MOUNTING

BY

1

80°

=%I

Figure

3G-5

Repositioning Tire on Wheel

There is no more work involved in repositioning a

tire on a wheel than there is in putting on a new tire,

and repositioning has a better chance of correcting

the difficulty.

It is important that only the tire/wheel assemblies

that are causing the disturbances be repositioned.

Since normally only one, and occasionally two, tire/-

wheel assemblies per vehicle could be causing the

disturbing vibration, it is recommended that reposi-

tioning be performed only when required. Reposi-

tioning of non-disturbing assemblies could cause

these assemblies to create vibration or roughness

problems.

After repositioning, balancing the tire/wheel assem-

bly is always necessary. It is very important that the

tire/wheel assembly be balanced accurately.

At this point, the car should be road-tested again to

assure that the disturbance has been corrected.

Tire Grinding

Tire grinding is

.very

effective in eliminating tire

complaints due to excessive tire runout. Grinding

can be accomplished on or off the car. Grinding is

approved by Opel, if done as recommended by the

equipment manufacturer

Figure

3G-6

Tire Rotation

Loading...

Loading...