21

Appendix B

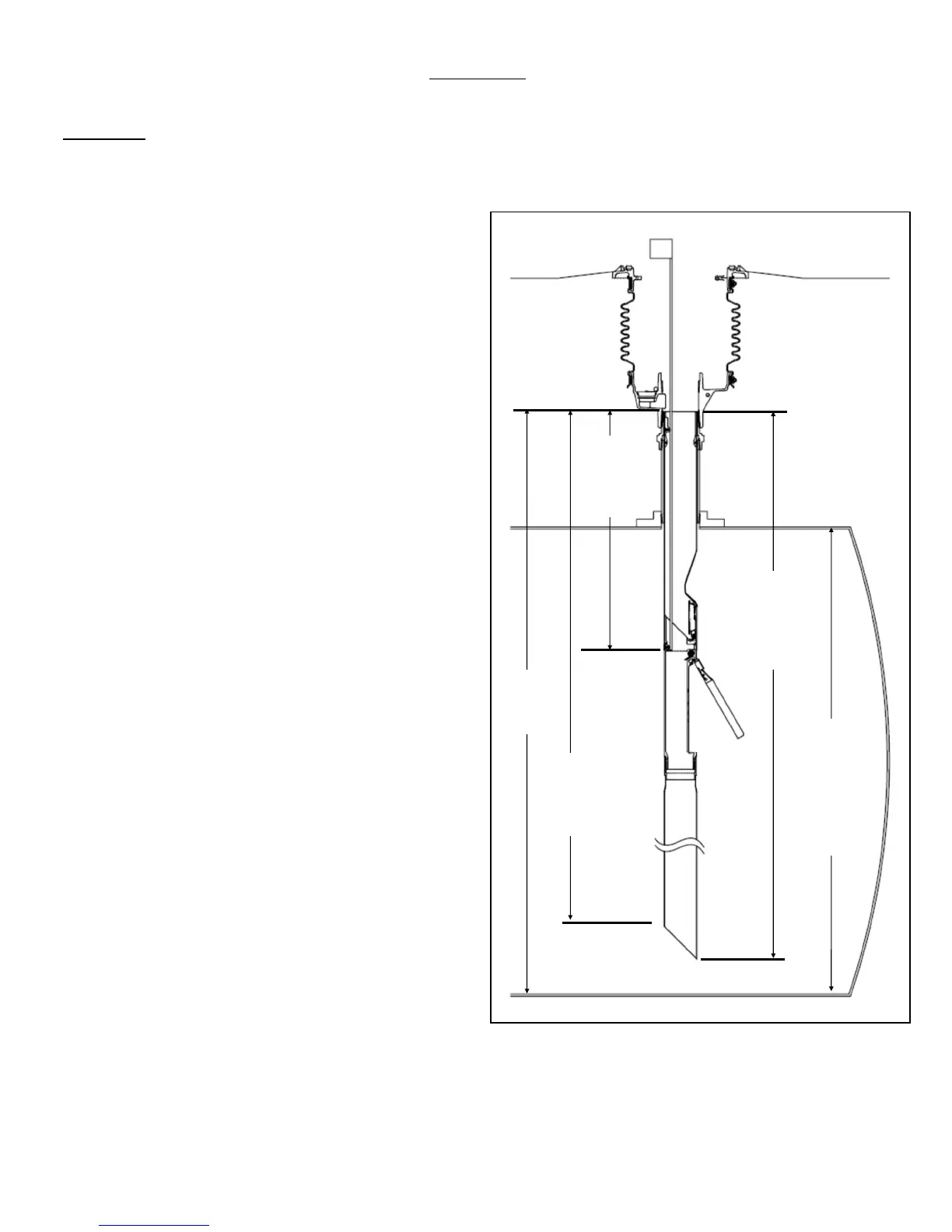

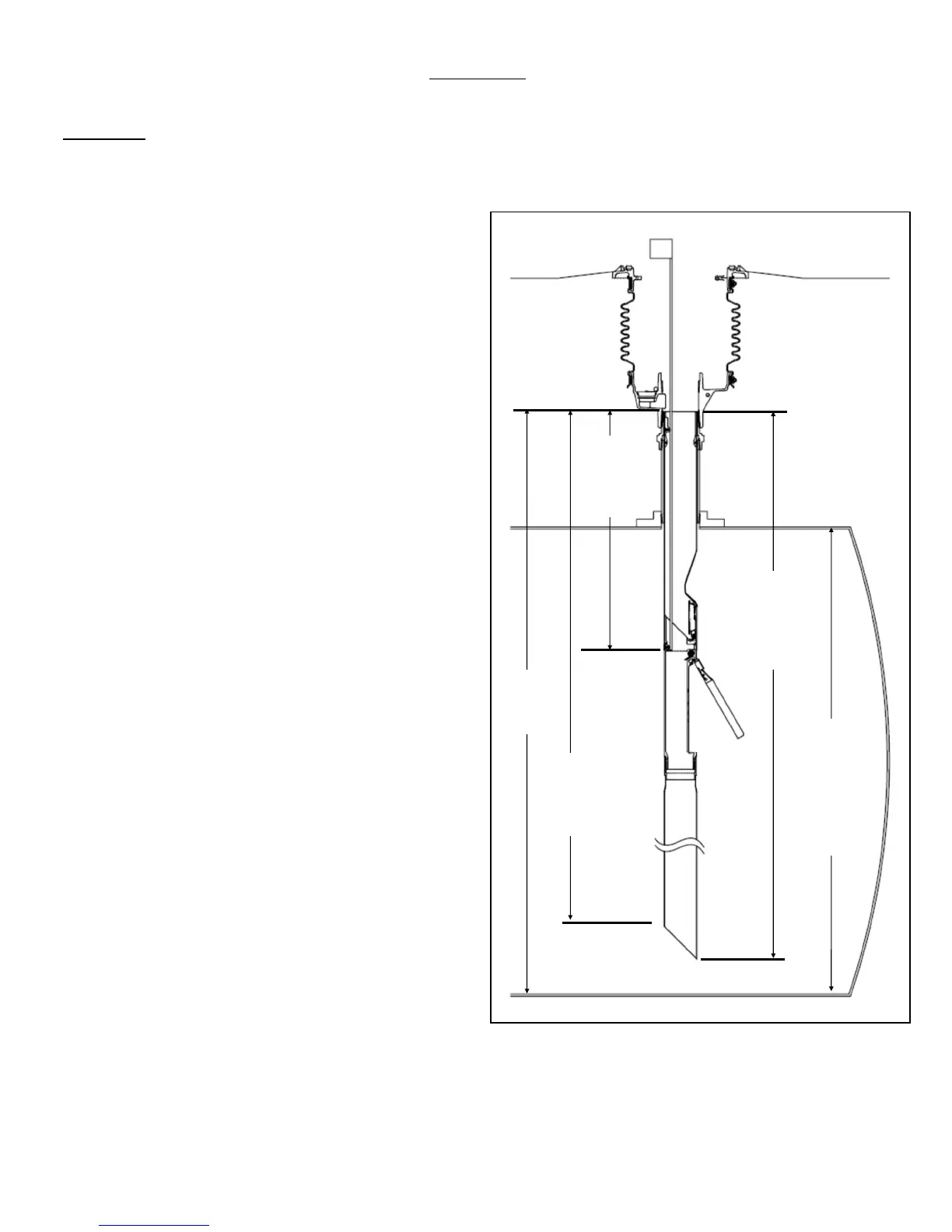

71SO Overll Valve in Tank Shut o Level Worksheet

Important: This is meant to be supplemental worksheet and not a substitute to following the installation

manual instructions. All length measurements are in inches. Please contact the Authority Having Jurisdic-

tion (AHJ) and review local, state, and national codes to determine the regulatory requirements governing

shut-o capacity in your region, as well as take into account other considerations such as extreme tank tilt.

Take the following measurements with the valve in-

stalled in the tank:

Distance from the 71SO inlet tube ange to the cast

lug in the 71SO body (see gures), upper tube length.

Note: the Upper Tube Length must be at least 16” to in-

clude the protective bend in the tube.

(D) = ______________________

Distance from the 71SO inlet tube ange to the top and

bottom of lower tube, valve length.

(W) = _____________

(U) = _____________

Distance from the 71SO inlet tube ange to the bottom

of the tank. Note: If a tank bottom protector is present it

may be necessary to add this thickness to dimension

(OPW 6111 & 61TP models add 0.6”)

(B) = _____________

From the tank calibration chart provided by tank manu-

facturer nd the dipstick number (Y) which corresponds

to the 100% volume.

(Y) = _____________

1. To determine shut-o percentage:

Subtract upper tube length (D) from distance to tank

bottom (B)

(X) = (B) – (D) - 2” =________________________

Using the tank calibration chart provided by the tank

manufacturer determine the tank capacity at the cal-

culated (X) dimension and the 100% volume (Y) tank

capacity.

(X) tank capacity in gallons = _______________

(Y) tank capacity in gallons = _______________

SO% = (X) capacity / (Y) capacity x100 = __________

Note: The overll valve must be installed per AHJ require-

ments and all applicable local, state, and national codes. If

the overll valve is set above the allowable shut-o percent-

age the overll valve must be removed and replaced. For

reference 40 CFR part 280 Subpart B Section 280.20 overll

valves should be set to a maximum of 95%.

(B)

To Tank

(D)

Upper

Tube

(W) Valve

Length,

bottom of

cut

(Y)

Tank

Chart

100%

Volume

Dipstick

(U) Valve

Length,

top of cut

Loading...

Loading...