9

Connection

6.3 Grounding

The wire used to ground the motor and driver must be as thick and short to the grounding point as possible so that no

potential dierence is generated. Choose a large, thick and uniformly conductive surface for the grounding point.

z

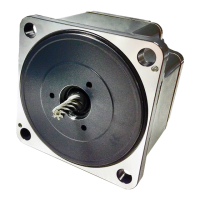

Grounding the motor

Connect the grounding wire along with a

set screw to the grounding point, using a

shakeproof washer.

For the 15 W type motor, remove the paint from

the mounting surface of the geared motor, and

install it to a metal surface that has grounded.

z

Grounding the driver

Install the driver to a metal surface that

has grounded.

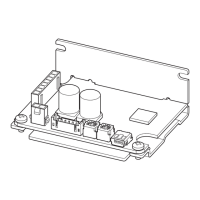

6.4 Connecting the I/O signals (CN2)

Insert the connector of the I/O signal cable into the I/O signal connector (CN2) of the driver.

Lead wire size: AWG26 (0.14 mm

2

)

CN2 pin assignment

Viewed from the direction of an arrow in the right gure

VR2CN2

21

43

65

87

109

1413

1211

Housing: PHDR-14VS (JST)

Terminal: SPHD-001T-P0.5 (JST)

Pin

No.

Lead wire

color

Terminal

name

Initial assignment

signal

*1

Description

14 Yellow/Black DIN0 [START/STOP]

These signals are used to operate the motor.

The motor rotates according to the acceleration time when both the

START/STOP input and the RUN/BRAKE input are turned ON.

If the START/STOP input is turned OFF, the motor stops according to the

deceleration time. If the RUN/BRAKE input is turned OFF, the motor stops

instantaneously.

13

Orange/

White

DIN1 [RUN/BRAKE]

12 Red/White DIN2 [FWD/REV]

This signal is used to change the motor rotation direction.

The motor rotates in the forward direction when the signal is turned ON.

*2

11 Brown/White DIN3 [M0]

The operation data number can be selected based on a combination of

ON-OFF status of the M0 and M1 inputs.

10 Black DIN4 [M1]

9 White DIN5 [ALM-RST]

This signal is used to reset the alarm.

(The alarm will be reset at the ON edge of the input.)

8 Gray VH

External analog

setting device

*3

These terminals are used when the rotation speed or torque limiting

value is externally set using an external analog setting device (external

potentiometer or external DC voltage).

7 Purple VM

6 Blue VL

5 Green GND GND I/O signals common

4 Yellow DOUT0 [SPEED-OUT] 30 pulses are output while the motor output shaft makes one revolution.

3 Orange DOUT1 [ALM-B]

This is a signal to output an alarm status.

It is turned OFF when an alarm is generated. (Normally closed)

2 Red DOUT2 [TLC] This is a signal to output when the motor output torque is limited.

*4

1 Brown DOUT3 [DIR]

This is a signal to output information of the motor rotation direction.

(It is turned ON when the motor rotates in the forward direction.)

*1

A signal assigned at the time of shipment is described in brackets [ ]. Functions for the pin No.1 to No.4 and No.9 to No.14

can be changed using the MEXE02.

*2

The rotation direction of the output shaft varies depending on the gear ratio of the gearhead.

The rotation direction can be changed by setting of the "Motor rotation direction" parameter.

*3

If the "External setting method" parameter is changed, the rotation speed and torque limiting value can be set with the

PWM signal input.

*4

The torque limiting value is set to 200% at the time of shipment and can be changed using the MEXE02.

Loading...

Loading...