Positioning

Temperature Control

■ New PID Command (F356 EZPID) Produces a Temperature

Control Program only in a Single Line.

■ Multi-point PID control

Modbus-RTU

Multiple temperature

controllers

Easy unification of

data management

The high-level PID control easily achieves high-speed, high-accuracy

multi-point temperature control.

R0

Control code

Y0

F356 EZPID, WR1, WX1, DT0, DT100

Measured value Target value Output value Output address

When using the

previous F355 command

• Target value

• Control code

• PID control elements

When using the new

F356 PID command

• Target value setup

• Auto-tuning execution

Program

Only a

single line

Parameter setup

Auto-tuning setup

Start bit ON

Auto-tuning end

Start bit OFF

Parameter storage

PID command execution

Bit processing

Timer set value

conversion

PWM output circuit

PWM output

PWM output

frequency setup

Executing F356 PID command

Touch Panel

°C

t

SSR

Heater

Thermocouple

Constant Temperature

PWM output

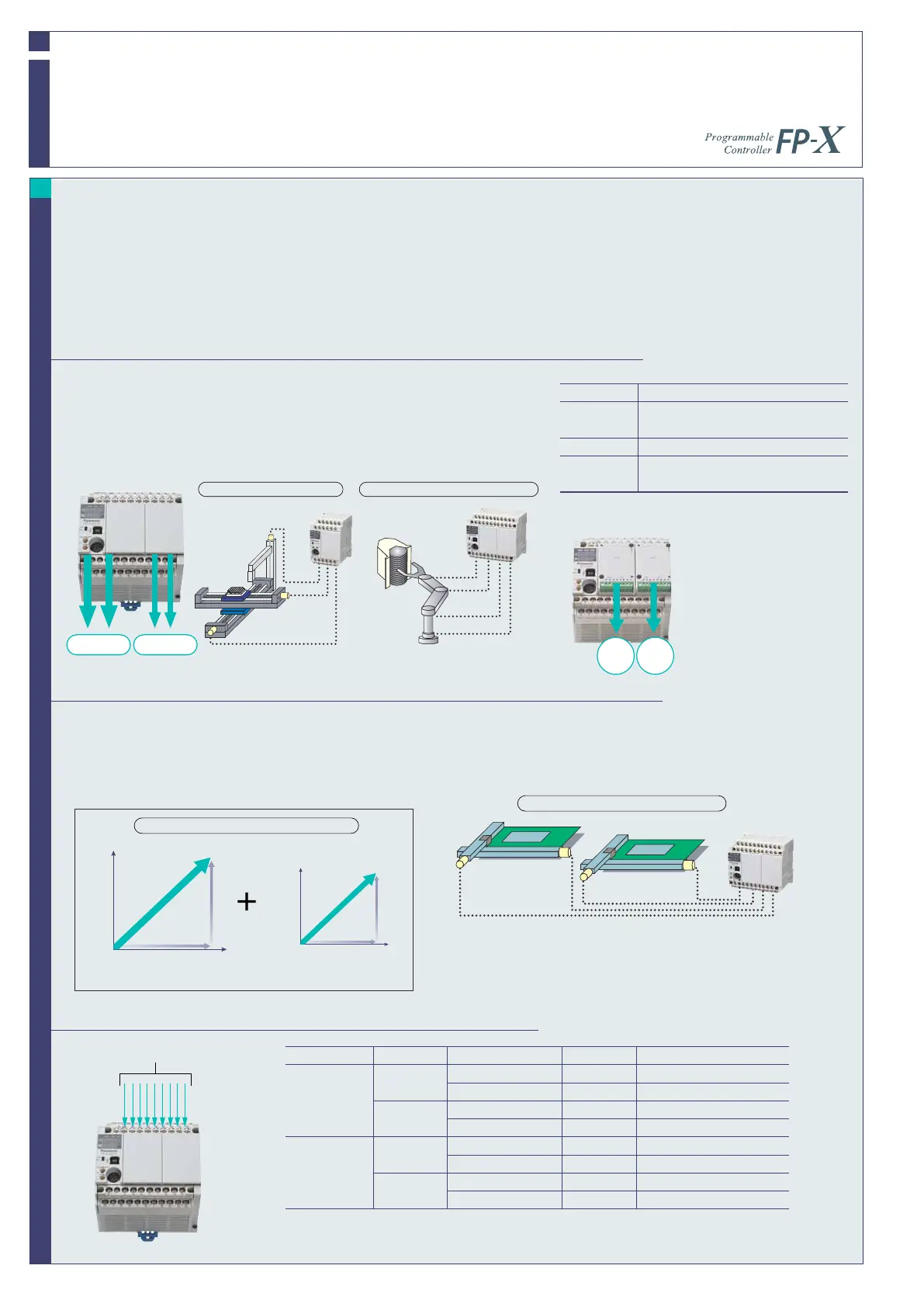

●The application of PLC-based temperature control has been

expanding such as multi-level temperature control, timer-

controlled temperature control, and a temperature control

relative to a variable based on a data computation results

etc. By using the new PID command (F356 EZPID), a PID

control program can be drastically simplified and the PLC-

based temperature control, which was previously thought

to be difficult by a PLC, can easily be achieved. The

example on the right, a simple uniform temperature control,

enables a surprisingly easily PID control with a single line

command by using a F356 command combined with a

touch-panel operation.

*1 Derivative type

*2 Proportional-derivative type

●High-accuracy PID control is possible by adopting a sophisticated

algorithm and floating-point operations.

●Higher accuracy is obtained by ultra high-speed computations in a

32 µs/loop. For example, a 16-loop control only adds a scan time of

0.5 ms by ensuring minimum impact on the tact time.

●The simultaneous multi-point auto-tuning simplifies complex

parameter setting.

●The high-speed control PI-D*

1

mode and overshoot suppression I-PD*

2

mode are available for selection according to the intended application.

●By combining with a sequence control, the parameters (Kp, Ti, Td, etc.)

can be changed during a PID control execution, thereby enabling

optimum temperature control in each stage including start up, mid-

range, and convergence.

The ability to change the target value easily enables multi-step

temperature control, which was difficult only with temperature

controllers. In addition, the multi-point temperature control enables

the centralized control of multiple temperature controllers with a

single FP-X for unified data management.

Two modes are selectable

Partial optimum control by changing parameters Multi-step control by changing the target value

PI-D mode

I-PD mode

Time

Target

value

Time

Target

value

Time

Target value

Overshoot suppression

Rapid acceleration

Smooth startup

High-speed PID

control

FP-X

The number can even be increased up to 28 channels by using

the thermocouple input cassette and FP0 thermocouple unit.

T/C T/C T/C T/CT/C

10 11

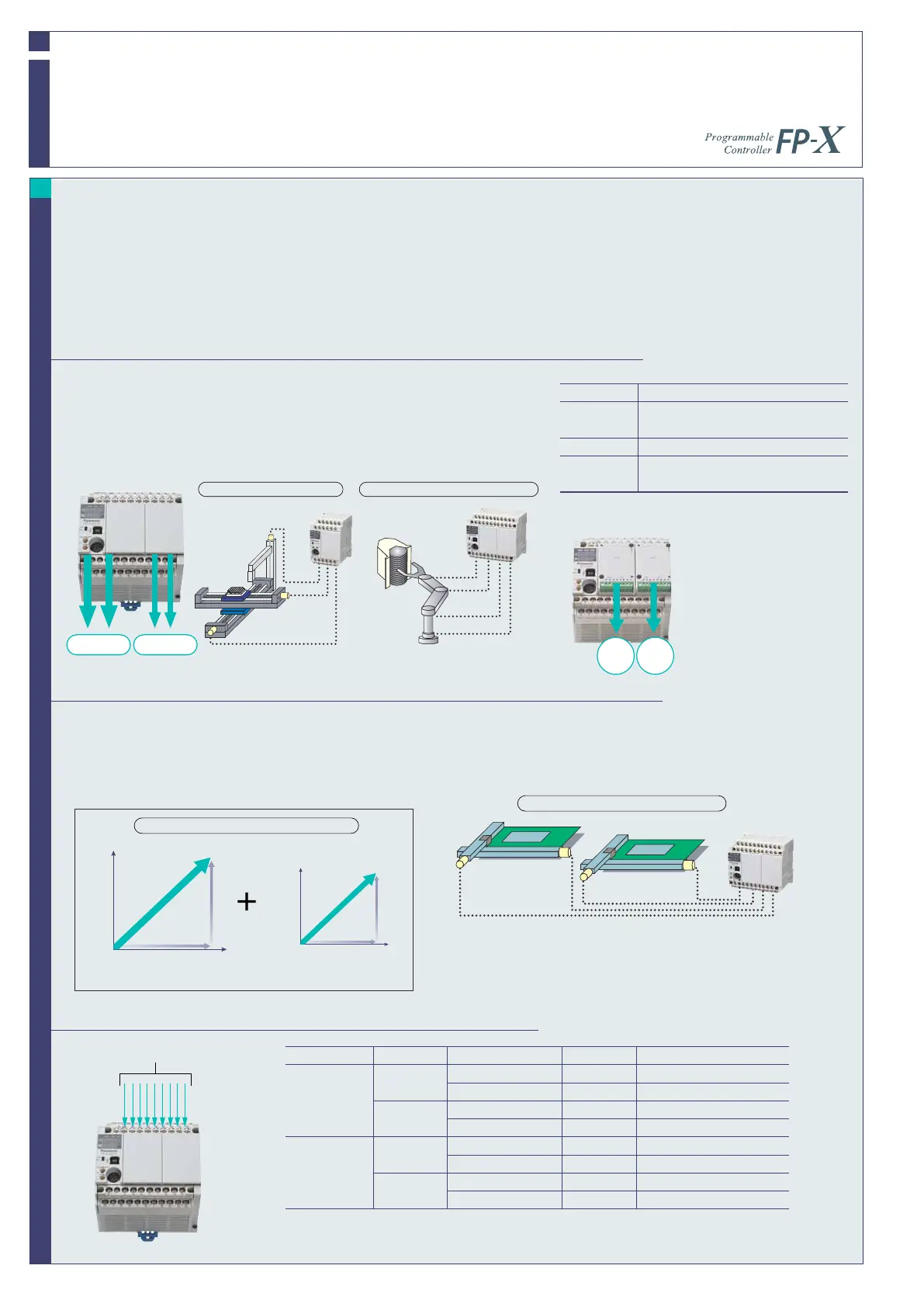

FP-X perfectly fits the need for low cost “multi-axis positioning control

in small-scale equipment”

■ Built-in 4-axis Pulse Output (Transistor Output Type)

The transistor output type C14 comes with 3-axis while C30/C60 comes with 4-axis

pulse output inside the control unit. The multi-axis control, which previously

required a higher-level PLC or additional positioning unit, or two or more PLC units,

can now be achieved with only one FP-X transistor output type unit in a small

space at a low cost. In addition, as this type does not require a pulse I/O cassette

needed for a relay output type, other function expansion cassettes such as

communication or analog input can be attached for more diversified applications.

2-axis linear interpolation refers to moving a robot arm or equipment head diagonally on a straight line by

simultaneously controlling two motor shafts. It is used for palletizing, component pick and place, XY table

control, contour cutting of a PC board etc. FP-X transistor output type is capable of simultaneously

controlling 2-axis linear interpolation, for the first time in the industry with a compact pulse-output PLC.

This unit drastically expands the range of applications along with the added convenience of programming

by using the linear interpolation commands F175 (SPSH).

■ 2-axis Linear Interpolation Simultaneously in two Sets (Transistor Output Type)

■ High-Speed Counters – Eight Built–in Sets

XY Table + Processing Head Semiconductor Wafer Takeout Blade

Eight single-phase or four dual-phase

sets (X0~X7)

3-axis Control with C14. 4-axis Control with C30/C60

Controls Two Units of 2-axis XY Table

C30/C60

100kHz x

2 axes

20kHz x

2 axes

Pulse Output

Max Frequency

Output Type

Function

C14: 100kHz(CH0,1), 20kHz(CH2)

C30,C60: 100kHz(CH0,1), 20kHz(CH2,3)

CW/CCW, Pulse + Direction Output

Trapezoidal control, multi-stage

operation, jog operation, origin return,

2-axis linear interpolation

Item Specification

● The relay output type can control two axes by

using the expansion cassettes

X-axis (CH0)

Simultaneous Control of Two Mechanisms

Maximum

composite speed

100kHz

Y-axis

(CH1)

X-axis

(CH2)

Maximum

composite speed

20kHz

Y-axis

(CH3)

By adding two pulse I/O cassettes (AFPX-PLS), linear

interpolation is possible at the maximum composite speed of

80kHz. The command used for this unit is F175 (SPSH), same

as that for the transistor output types.

● The relay output type is also capable of 2-axis linear interpolation.

When adding a pulse I/O cassette to the relay output type, two high-speed counter sets can

be added to every cassette. Please refer to the user manual for counter specification.

Transistor

output type

Relay output

type

Single Phase

Dual Phase

Single Phase

Dual Phase

During Halt

During Operation

During Halt

During Operation

During Halt

During Operation

During Halt

During Operation

100kHz

35kHz

35kHz

15kHz

10kHz

10kHz

5kHz

5kHz

50kHz × 4ch + 10kHz × 4ch

25kHz × 4ch + 10kHz × 4ch

25kHz × 2ch + 5kHz × 2ch

10kHz × 2ch + 5kHz × 2ch

10kHz × 8ch

10kHz × 8ch

5kHz × 4ch

5kHz × 4ch

Model Type Input Mode

Pulse Output (four axes)

One ch in use All channels in use

First

axis

80kHz

Second

axis

80kHz

Pulse output up to 2-axis

80kHz is possible by

loading two pulse I/O

cassettes (AFPX-PLS).

Also capable of

performing 2-axis linear

interpolation.

Remark)

Pulse I/O cassette doesn’t work

with control unit transistor output

type.

Loading...

Loading...