Do you have a question about the Parker Hiross Hyperchill ICE001 and is the answer not in the manual?

Key operational and safety guidelines for the unit, including user responsibilities and manufacturer liability.

Identifies potential hazards not eliminated in the design phase and necessary precautions.

Instructions for handling the unit during transport, including orientation and protection requirements.

Guidance on using appropriate lifting equipment and avoiding impacts during handling.

Procedures for checking the unit upon arrival, including immediate notification of damage.

Recommendations for storing the unit safely, including protection from elements and stacking restrictions.

Requirements for liquids used in the circuit, including compatibility, flammability, and environmental considerations.

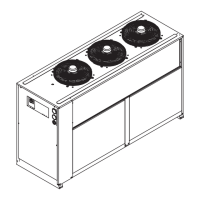

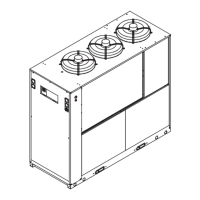

Minimum space required around the unit for proper operation and ventilation.

Notes on unit versions, specifically regarding axial fans and ventilation grille obstructions.

Details on water circuit installation, cleaning, checks, and connections.

Guidance on using ethylene glycol as antifreeze, including specific weight values and recommended percentages for different temperatures.

Recommendation for installing an expansion tank to manage fluid volume changes due to temperature variations.

Procedures for initial electrical checks, power supply connection, and subsequent verification of grounding and protection.

Description of the control panel components, including buttons (P1, P2, P3, S1) and indicators (L1, L2, L3, H1, A1).

Step-by-step instructions for turning on the chiller and setting the desired temperature.

Procedure for safely shutting down the chiller by turning off the On/Off switch.

Overview of parameter protection levels (Direct and Password) and detailed settings for Chiller, Sensor, Regulator, and Compressor parameters.

Visual guide illustrating the navigation and operation of parameter management through the control interface.

List of alarm codes (EO, EEV), their descriptions (Control sensor error, Data acquisition error), and reset method (M).

Essential safety precautions before maintenance, using original parts, and handling refrigerant leaks.

Recommended maintenance tasks and schedules, including cleaning condenser fins and installing maintenance kits.

Details on refrigerant charging safety, classification (R407C), and GWP, with precautions for leakage.

Procedures for recovering refrigerant and lubricating oil, and a table for recycling/disposal of unit components.

Explanation of symbols, abbreviations, and units used in the manual, covering technical terms and components.

| Brand | Parker Hiross |

|---|---|

| Model | Hyperchill ICE001 |

| Category | Chiller |

| Language | English |