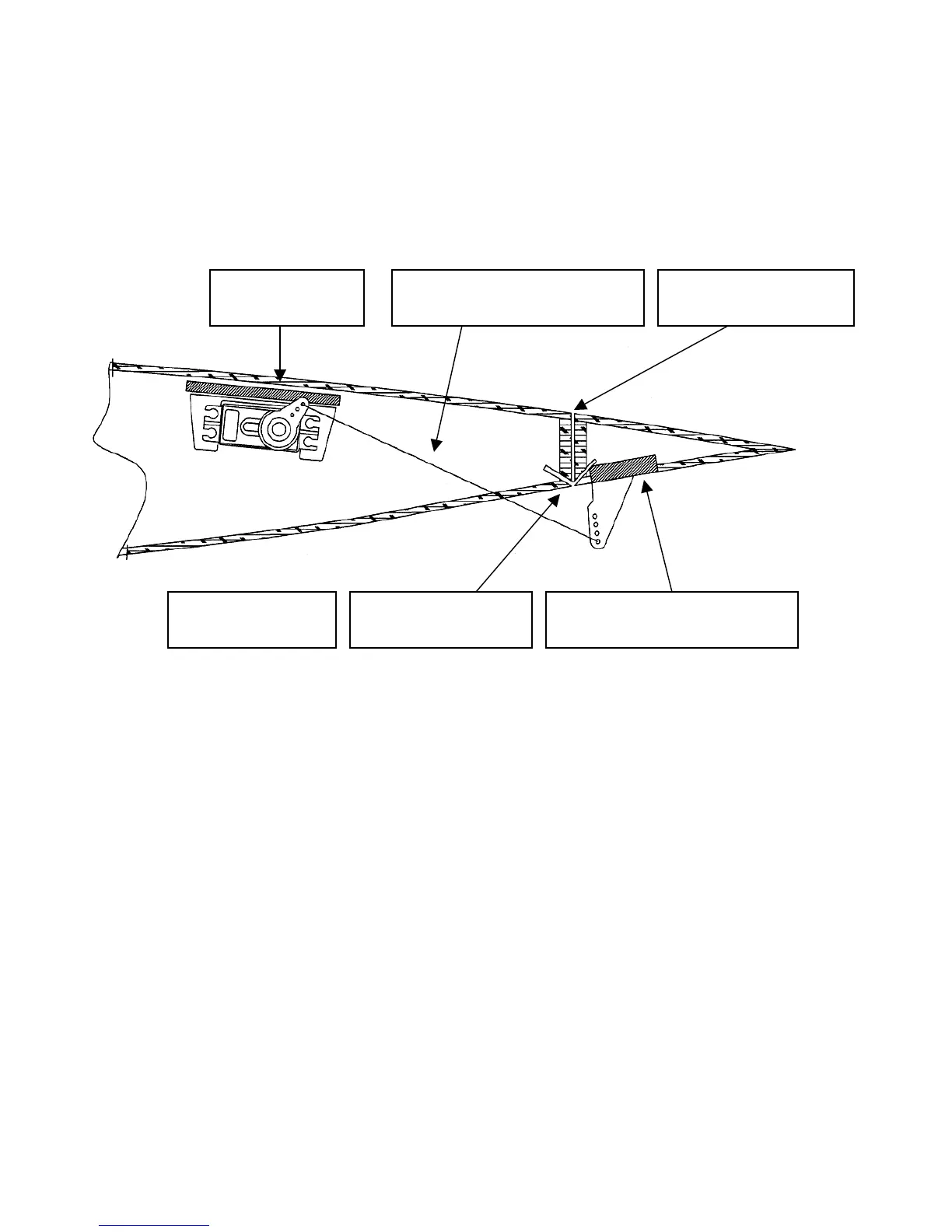

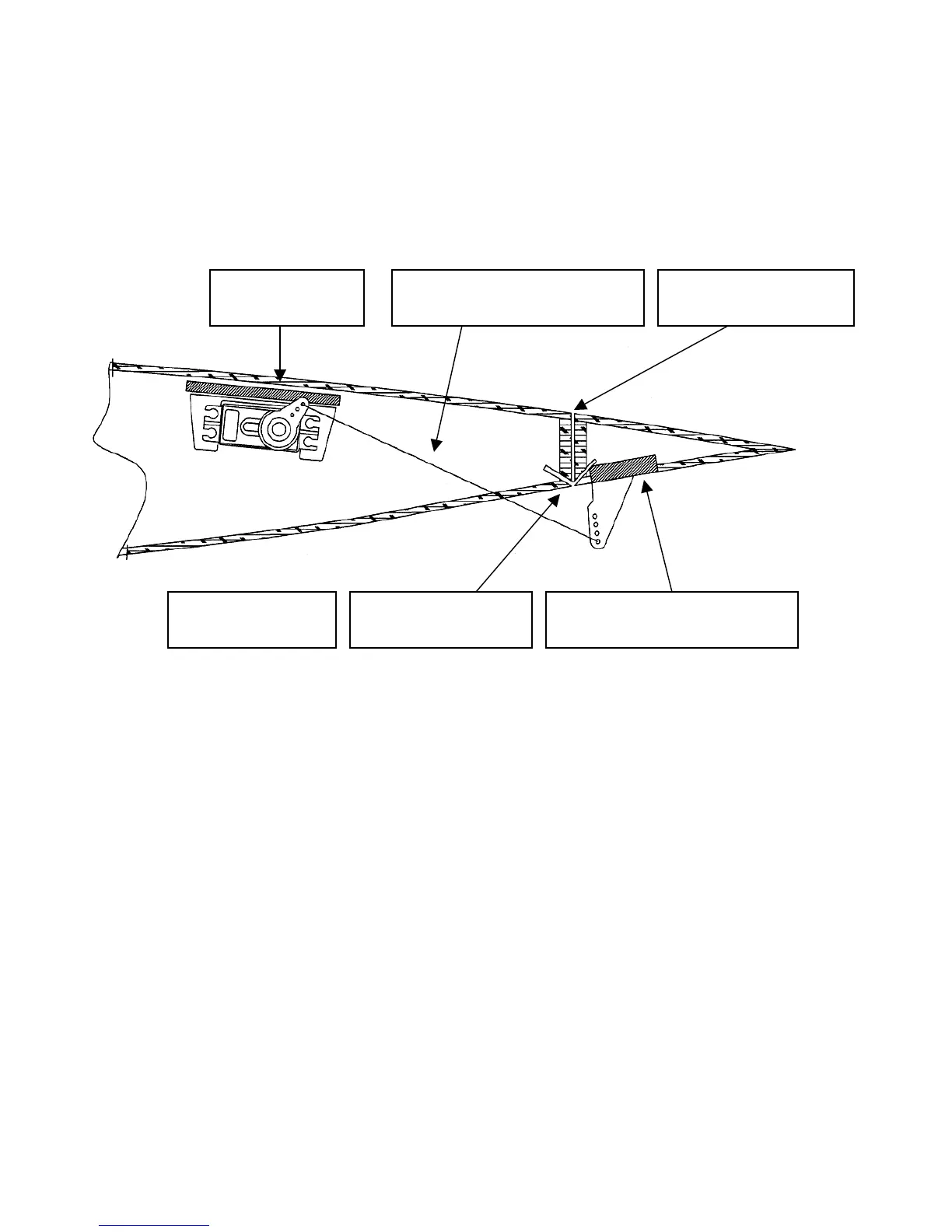

The two Flap servos are located within the gear bays. The 4-40 pushrod runs

underneath the gear leg (when retracted) and passes through the balsa sheeting and

out to the horn located in the top of the flap. The Flap is Bottom hinged.

Flap Detail Diagram

ote position of servo arm

and horn when flap is raised

ote there is no bevel

on the flap LE.

Flap is hinged on the

bottom as shown.

Steel control horn mounted on

¼ ply base embedded in wing

Servo mounted

in ServoPr

This drawing is

not drawn to scale

The servo is located between WR3 and WR2just in front of the retract air cylinder.

The horn is oriented towards the top sheeting as shown in order that the pushrod has a

straight shot to the control horn. It is important that you make sure your geometry of

the pushrod is correct. A flap, unlike an aileron or elevator is not at neutral travel in

the center rather it is at the end of its travel in one direction (raised) and then passes

through the mid way point on its way to full deployment. Ideally, the geometry of the

servo arm, pushrod and control horn should be at right angles when the flap is at half

travel. Note relative position of the control horn clevis pivot point and hinge point

location.

When the location of the control horn is determined, Imbed a ¼ x ¾ x 1-1/4 Plywood

Control horn base flush with the sheeting. First cut away the balsa skin then remove

enough foam underneath for the base to sit level. Use 5-minute epoxy

The control horn is mounted to the base with the supplied button head screws.

33

Loading...

Loading...