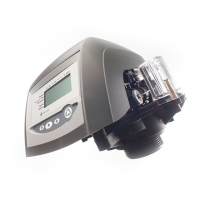

Installer Manual Magnum 742-762 - Installation

36 / 106 Ref. MKT-IM-012 / C - 25.10.2019

5.2.3. Mechanical

• Do not use petroleum-based lubricants such as vaseline, oils, or hydrocarbon-based lubricants.

Use only 100% silicone lubricants;

• all plastic connections should be hand tightened. PTFE (plumber’s tape) may be used on

connections that do not use an o-ring seal. Do not use pliers or pipe wrenches;

• all plumbing must be completed according to local codes;

• soldering near the drain line should be done before connecting the drain line to the valve.

Excessive heat will cause interior damage to the valve;

• the drain line may be elevated up to 1.8 m providing the run does not exceed 4.6 m and water

pressure at the softener is not less than 2.76 bar. Elevation can increase by 61 cm for each

additional 0.69 bar of water pressure at the drain connector;

• do not use lead-based solder for sweat solder connections;

• to prevent mineral loss during backwash and to ensure proper operation of the valve, a drain line

flow control must be plumbed into the drain line prior to placing the valve in service mode. Flow

controls from 18.92 to 151.4 L/min can be easily installed in the drain line. Flow controls greater

than 151.4 L/min must be plumbed externally. The selection of the proper drain line flow control

depends on the tank size and media used for the installation;

• the drain line must be a minimum of 12.7 mm (½") in diameter. Use 19 mm (¾") pipe if the

backwash flow rate is greater than 26.5 lpm or the pipe length is greater than 6 m;

• do not support the weight of the system on the control valve fittings, plumbing, or the bypass;

• it is not recommended to use sealants on the threads. Use PTFE (plumber’s tape) on the threads

of the 25.4 mm (1") NPT elbow, the drain line connections, and other NPT/BSP threads.

5.2.4. Outdoor Locations

When the water conditioning system is installed outdoors, several points must be considered:

• moisture — The valve and 700 controller are rated for NEMA 3 locations. Falling water should

not affect performance. The system is not designed to withstand extreme humidity or water

spray from below. Examples are: constant heavy mist, near corrosive environment, upwards

spray from sprinkler;

• direct sunlight — The materials used will fade or discolour over time in direct sunlight. The

integrity of the materials will not degrade to cause system failures;

• temperature — Extreme hot or cold temperatures may cause damage to the valve or controller.

Freezing temperatures will freeze the water in the valve. This will cause physical damage to the

internal parts as well as the plumbing. High temperatures will affect the controller. The display

may become unreadable but the controller should continue to function. When the temperature

drops back into normal operating limits the display will return to normal. A protective cover

(P/N 1267811) should assist with high temperature applications;

• insects — The controller and valve have been designed to keep all but the smallest insects out of

the critical areas. Any holes in the top plate can be covered with a metal foil ductwork tape. The

top cover should be installed securely in place;

• wind — The Logix cover is designed to withstand a 48 km/h (30 mph) wind when properly

installed on the valve.

Loading...

Loading...