Installer Manual Magnum 742-762 - Troubleshooting

88 / 106 Ref. MKT-IM-012 / C - 25.10.2019

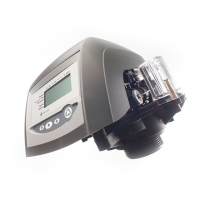

10.3. Magnum valve cartridge

The following procedure provides sequential troubleshooting steps to isolate a suspect cartridge.

Note

The dynamic pressure applied to the valve must be greater than 172.4 kPa at all times when

performing the following tests. If a cartridge needs to be removed, follow the removal

procedure in section 9.6.12. Cartridge replacement, page 83.

Loss of water

pressure.

Fouled resin bed due to iron

accumulation.

• Clean Magnum control valve and

mineral bed with cleaner.

Slots in riser pipe or laterals are filled

with resin fines.

• Inspect and clean distributor pipe

slots as needed.

Salt in water to

service after

regeneration.

The injector is too small for the system

size.

• Install the correct injector.

Brine draw time excessively long due

to low water pressure.

• Increase water pressure above

172 kPa minimum.

Restricted drain line.

• Remove drain line restriction.

Insufficient rinse volume.

• Increase slow rinse time, fast rinse

time or both.

Plugged injector and/or injector

screen.

• Inspect and clean the injector and/

or injector screen assembly.

Issue Cause Reset and recovery

#4 Inlet cartridge

#3 Outlet cartridge

#1 Drain cartridge

#2 Rinse cartridge

Loading...

Loading...