38 • FLECK 2850 Control Valve Service Manual

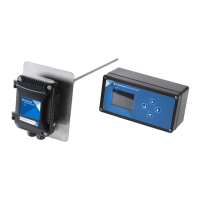

Figure 8

9. Alternately remove the remaining seals and spacers in

accordance with steps No. 6 and 8.

10. The last or end spacer does not have any holes for the pins of

the spacer tool to engage, therefore if the end spacer does

11. To replace seals, spacers and end ring, use special tool with

the brass sleeve on one end. This is a double-purpose tool.

The male end acts as a pilot to hold the spacers as they are

pushed into the valve body and the brass female end is used

to insert the seals into the

valve body.

Figure 9

12.

brass ring without holes), then with your thumb press the

button on the brass sleeve end. The large dia. inner portion

is now exposed (see Figure 8). Place the end ring on this pilot

with the lip on the end ring facing the tool. Push the tool into

the valve body bore until it bottoms. While the tool is in the

valve body, take a seal and press it into the inside diameter of

the exposed brass female end.

13. Remove the tool, turn it end for end and insert it into the

valve body bore. While holding the large dia. of the tool, slide

it all the way into the valve body bore until it bottoms. Then

push the center button to push the seal of the tool and leave

it in place in the valve body.

14. Remove the tool from the valve body and push the center on

the brass female end to expose the pilot on the opposite end.

Place a spacer on this end and insert the spacer and tool into

the valve.

SEAL & SPACER TOOLS & REPLACEMENT

CONTINUED

GENERALSERVICEHINTSFORMETER

CONTROL

Problem: Softener delivers hard water

Reason: Reserve capacity has been exceeded.

Correction: Check salt dosage requirements and reset program

wheel to provide additional reserve.

Reason: Program wheel is not rotating with meter output.

Correction: Pull cable out of meter cover and rotate manually.

Program wheel must move without binding and clutch must give

positive clicks when program wheel strikes regeneration stop. If

it does not, replace timer.

Correction: Check meter with meter checker.

Loading...

Loading...