Read all safety warnings before operation.

WARNING!

Failure to obey these warnings may result in loss of load, damage to engine crane, and/or

engine crane failure resulting in personal injury or property damage.

WARNING!

Do not overload engine crane beyond rated capacity of each specified boom position.

Overloading can cause damage to or failure of the crane.

Always use crane on hard, level surface capable of sustaining the load. Use of crane on

other than hard level surfaces can result in crane instability and possible loss of load.

Boom and load must be in lowest possible position before moving. Move load slowly and

smoothly to avoid uncontrolled swinging and possible loss of load.

Be sure all personnel are clear of the load before lowering.

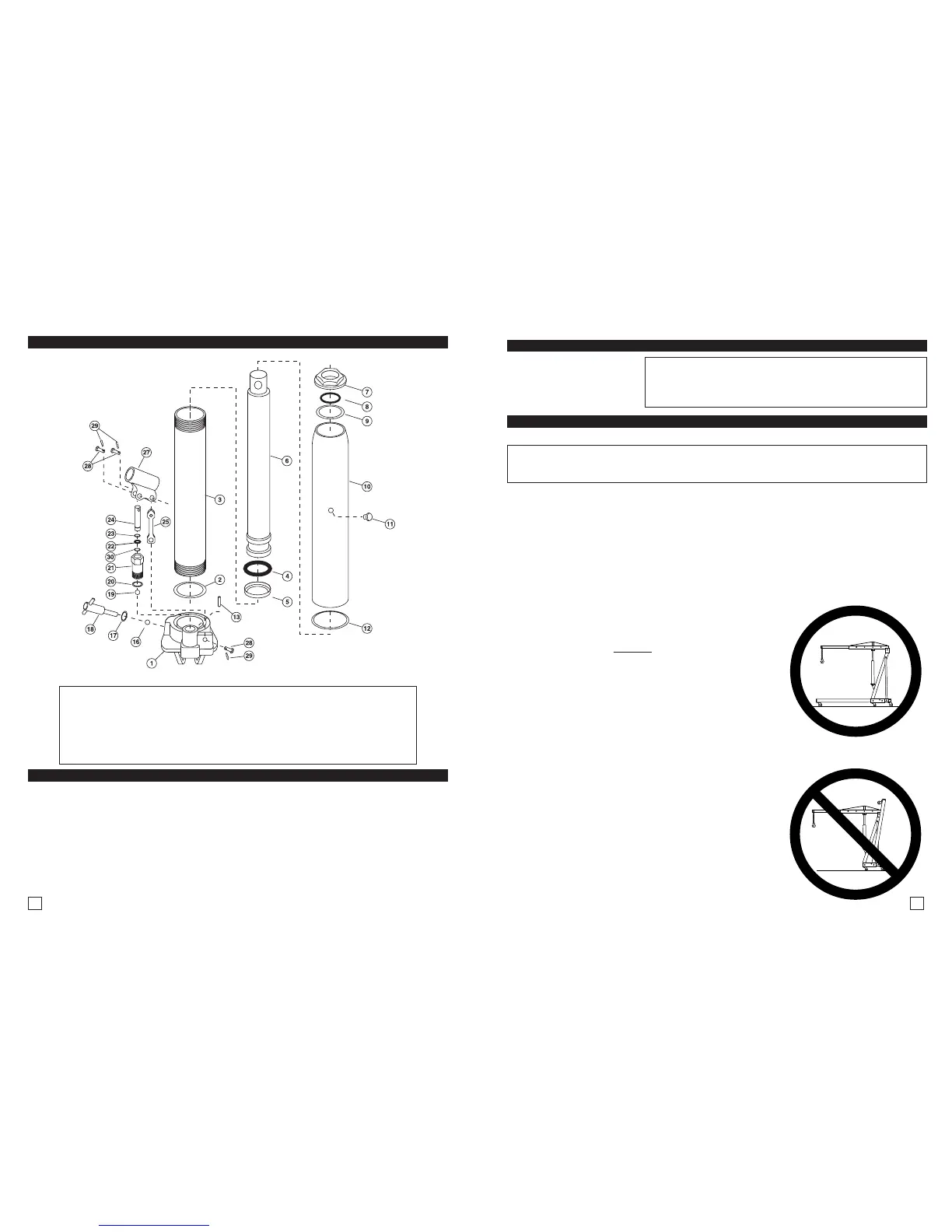

FRONT LEGS MUST ALWAYS BE LOCKED IN DOWN

POSITION BEFORE APPLYING LOAD AND/OR RAISING

BOOM (See Figure 2, page 5).

BOOM MUST BE IN FULLY LOWERED POSITION BEFORE

RAISING LEGS. LEGS MUST NEVER BE RAISED WHEN

CRANE IS CARRYING LOAD. LEGS MUST BE LOCKED IN

PLACE WHEN RAISED (See Figure 3, page 5).

NEVER WORK UNDER LOAD.

SPECIFICATIONS

Max. Capacity: ........... 4,000 lbs.

Base length: .......................... 69"

Base Width: ........................... 36"

Max. Height: (1/2 ton) ..... 90-3/4"

Max. Height: (2 ton) ........ 75-1/4"

Jack Capacity: (8 ton) 16,000 lbs.

Specifications are subject to change

without notice

IMPORTANT SAFETY INFORMATION

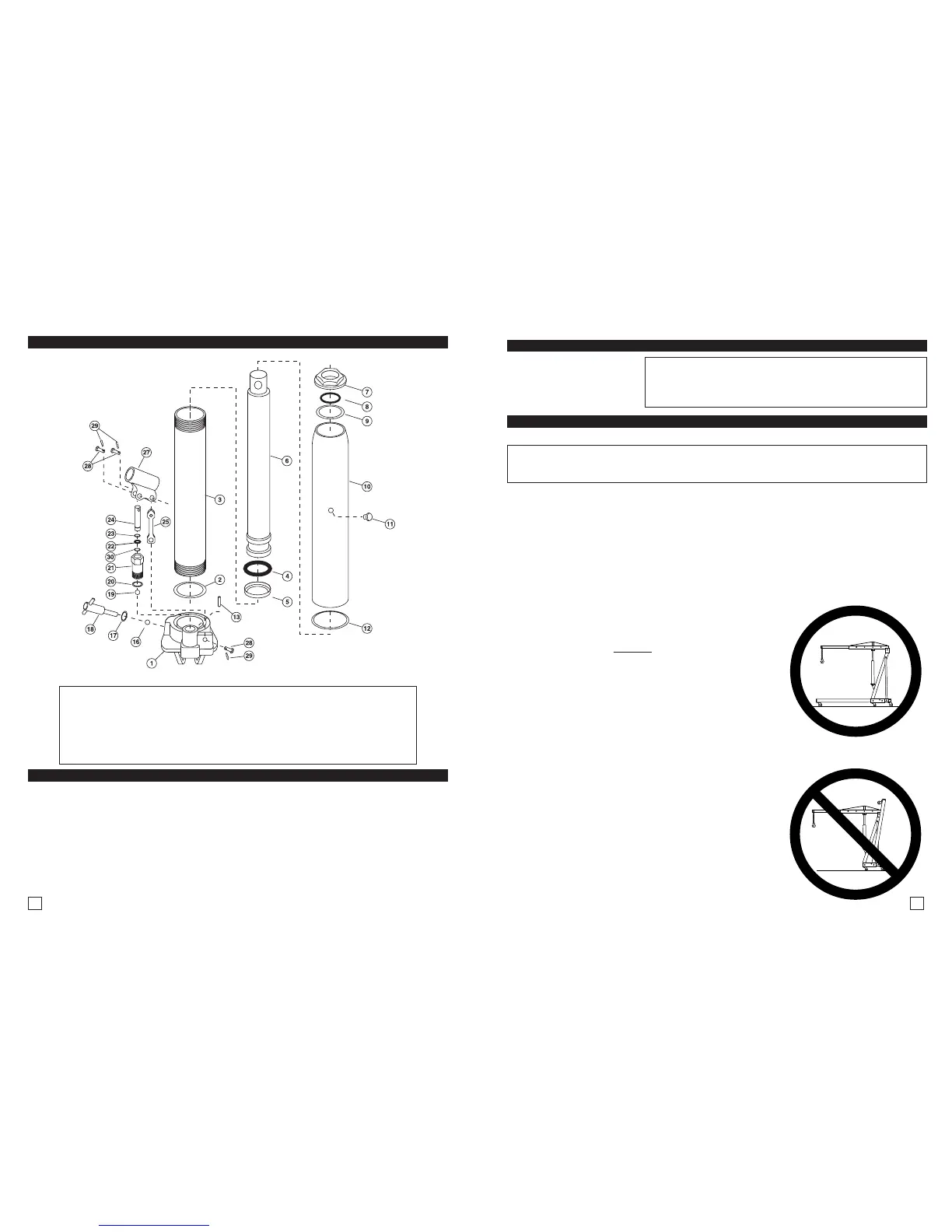

HYDRAULIC RAM ASSEMBLY

1. Visual inspection must be made before each use of the crane, checking for cracks, cracked welds

and missing and/or damaged parts. Any crane that appears to be damaged in any way must be

removed from service immediately.

2. BECAUSE OF THE POTENTIAL HAZARDS ASSOCIATED WITH THE MISUSE OF EQUIPMENT

OF THIS TYPE, NO MODIFICATIONS SHALL BE MADE TO THE PRODUCT.

3. Store crane with boom in fully lowered position and hydraulic ram valve closed when not in use to

prevent machined surfaces from exposure. Keep all moving parts clean and well lubricated.

4. Replace worn or damaged parts with Performance Tool replacement parts. Be sure that only

qualified personnel perform repairs.

MAINTENANCE and INSPECTION

# Description Qty.

1 Valve Body 1

2 Copper Washer 1

3 Cylinder 1

4 O-ring 1

5 O-ring Retainer 1

6 Ram 1

7 Top Nut 1

8 O-Ring 1

9 Sealing Gasket 1

# Description Qty.

10 Oil Chamber 1

11 Oil Plug 1

12 Seal Ring 1

13 Tube 1

16 Steel Ball 1

17 Seal Ring 1

18 Release Valve 1

19 Steel Ball 1

20 Copper Washer 1

# Description Qty.

21 Pump Cylinder 1

22 O-ring 1

23 Back-up Ring 1

24 Plunger 1

25 Link Pin 1

27 Handle Socket 1

28 Connecting Pin 3

29 Cotter Pin 3

36

Loading...

Loading...